Double helix pipe reactive tank ore pulp gas circulation device

A gas circulation and reaction tank technology, applied in the field of mineral processing, can solve problems such as insufficient oxygen, physical hazards of workers, and easy corrosion of motor stirring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

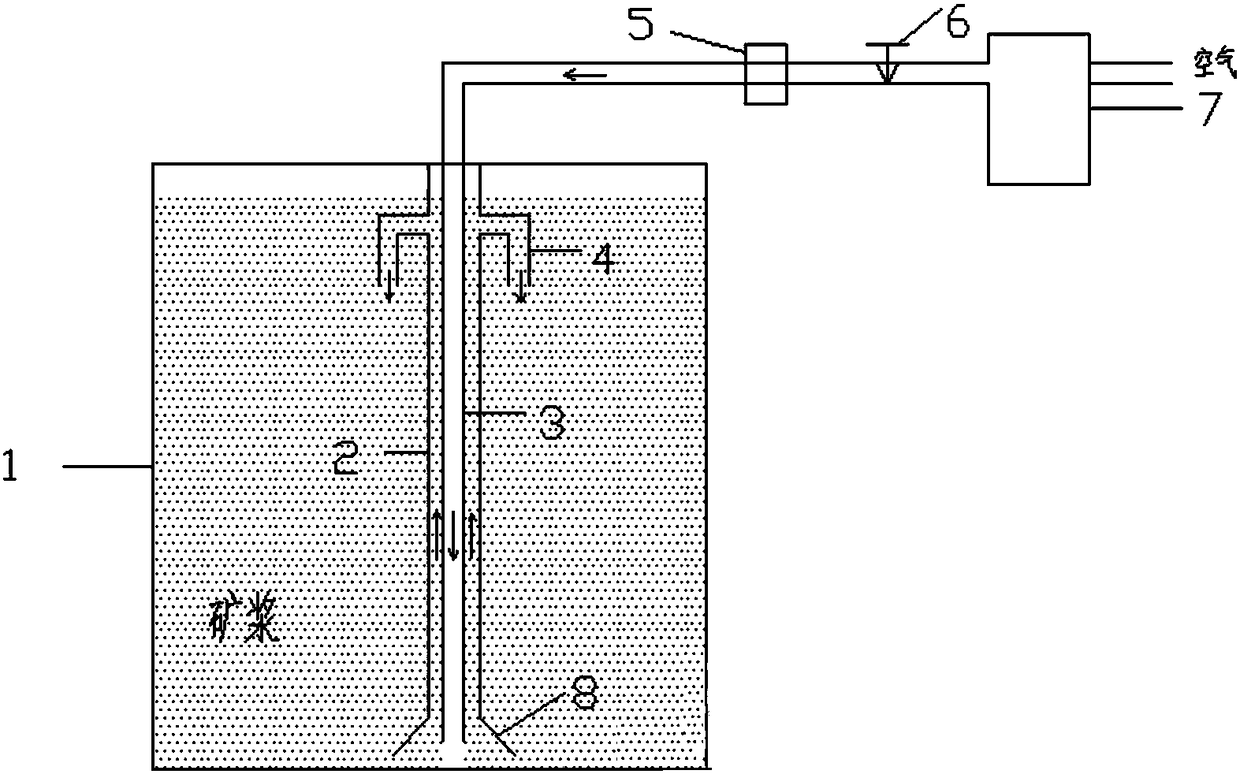

[0007] The present invention is specifically described below in conjunction with accompanying drawing, as figure 1 As shown, it includes a tank body 1, an air pipe 3 is arranged in the tank body 1, and a spiral pipe 2 is arranged on both sides of the air pipe 3; Pipe 4; the height of the lower end of the air duct 3 is lower than the height of the lower end of the spiral pipe 2; the lower end of the air duct 3 is arranged on the upper part of the collection cover 8; the upper end of the air duct 3 is connected with the air compressor 7 through a pipeline; Flow meter 5 and regulating valve 6.

[0008] The present invention uses an air compressor to compress the air, so that high-pressure air enters the bottom of the pulp in the reaction tank, and the high-pressure air makes the local pulp concentration smaller, and the surrounding pulp compresses this part, so that the local pulp rises into the circulation elbow, and then the pulp circulates in the entire reaction tank flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com