Separation method for phenolic compounds in rubus corchorifolius

The technology of a phenolic compound and a separation method is applied in the field of separation of phenolic compounds in raspberries, which can solve the problem of high difficulty in determination and separation, and achieve the effects of stable and reliable method, easy process control, and simple and effective method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Follow the steps below to perform pretreatment before separation of various phenolic compounds in raspberry

[0031] 1) 3g raspberry sample and 15mL acetone were placed in a 50mL centrifuge tube and stirred with a homogenizer at 15000rpm for 80 seconds to obtain a mixture of sample and acetone;

[0032] 2) and the mixture obtained in step 1) was filtered under vacuum, and the residue was washed 3 times with 5 mL of acetone, and the 3 times of filtrates were combined, wherein the filtering operation was carried out using a funnel filter paper, and a layer of glass was covered on the funnel filter paper cotton;

[0033] 3) Use a rotary condensation evaporator to evaporate the filtrate at 35°C until small yellow particles appear and stop evaporating;

[0034] 4) After evaporation, the concentrated sample was dissolved in 5 mL of 2% acetic acid, and passed through the C18Sep-Pak column, wherein, before the C18Sep-Pak column was used, it was activated with 5 ml of methanol,...

Embodiment 2

[0038] Follow the steps below to perform pretreatment before separation of various phenolic compounds in raspberry

[0039] 1) 3g raspberry sample and 15mL acetone were placed in a 50mL centrifuge tube and stirred with a homogenizer at 17500rpm for 1 minute to obtain a mixture of sample and acetone;

[0040] 2) and the mixture obtained in step 1) was filtered under vacuum, and the residue was washed 5 times with 5 mL of acetone, and the 5 times of filtrates were combined, wherein the filtering operation was carried out using a funnel filter paper, and a layer of glass was covered on the funnel filter paper cotton;

[0041] 3) Use a rotary condensation evaporator to evaporate the filtrate at 30°C until small yellow particles appear and stop evaporating;

[0042] 4) After evaporation, the concentrated sample was dissolved in 5 mL of 3% formic acid, and passed through a C18Sep-Pak column, wherein the C18Sep-Pak column was activated with 5 ml of methanol, 6 ml of deionized water,...

Embodiment 3

[0046] Follow the steps below to perform pretreatment before separation of various phenolic compounds in raspberry

[0047] 1) 3g raspberry sample and 15mL acetone were placed in a 50mL centrifuge tube and stirred with a homogenizer at 20000rpm for 40 seconds to obtain a mixture of the sample and acetone;

[0048] 2) and filter the mixture obtained in step (1) under vacuum, and wash the residue 3 times with 5 mL of acetone, and combine the 3 times of filtrate;

[0049] 3) Use a rotary condensation evaporator to evaporate the filtrate at 40°C until small yellow particles appear and stop evaporating;

[0050]4) After evaporation, the concentrated sample was dissolved in 5 mL of 5% formic acid and passed through a C18Sep-Pak column;

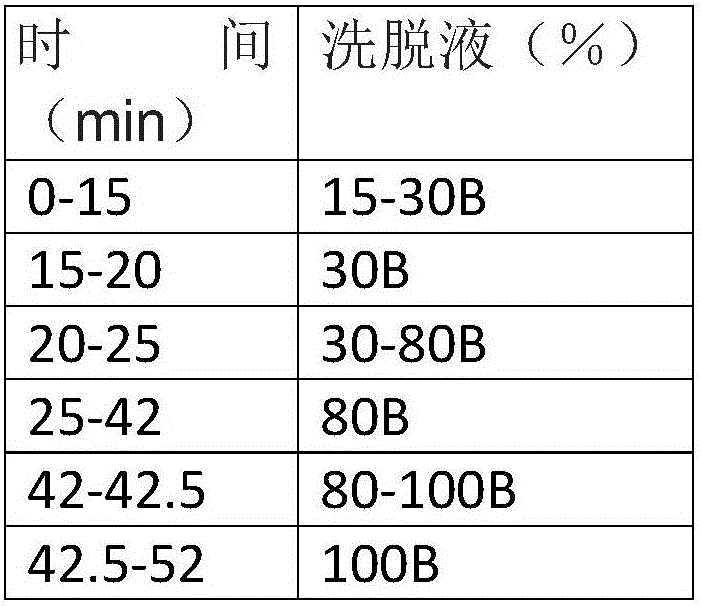

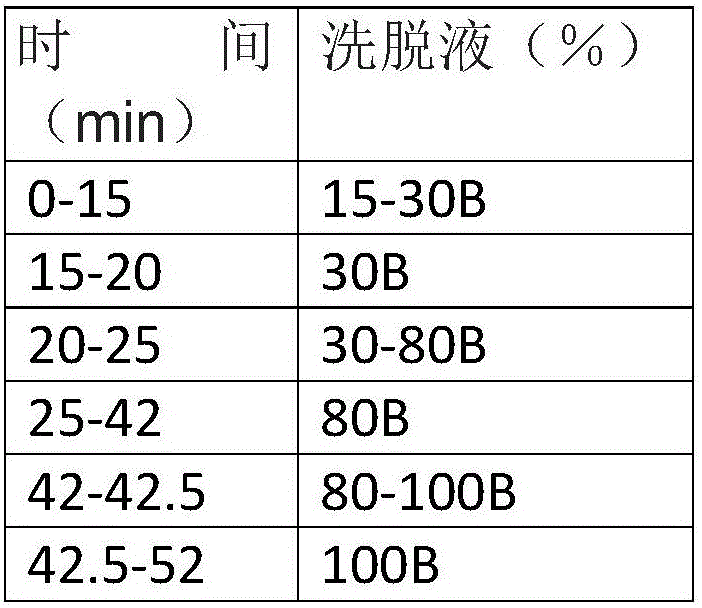

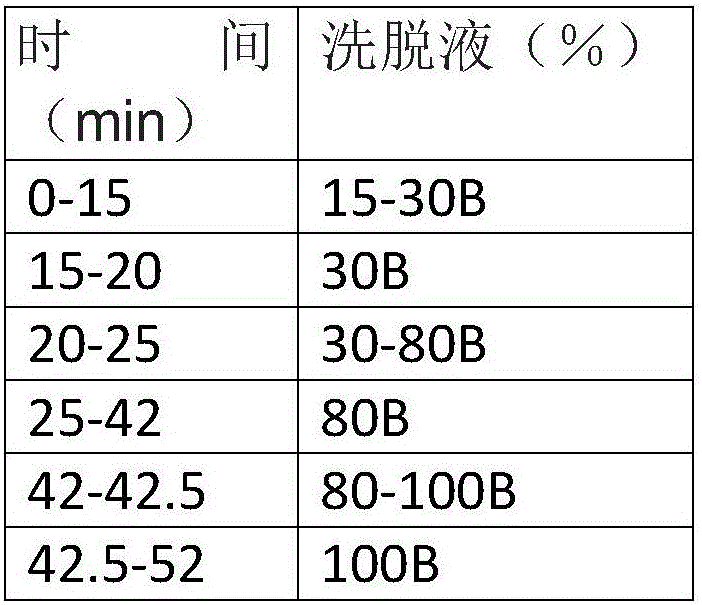

[0051] 5) Reactivate anthocyanins and other phenolic compounds with 2 mL of acidified methanol containing 5% formic acid and recover them. All recovered samples are filtered through a 0.45 μm syringe filter, and 10 μL of each sample’s extract is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com