Manufacturing method of spectacle lens with meshes

The technology of a spectacle lens and a manufacturing method, which is applied in the field of glasses, can solve problems such as inability to cut off and eliminate strong light, fail to achieve visual effects, and fail to achieve eye protection effects, so as to relieve eye fatigue, have good eye protection effects, and improve vision. effect of object

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

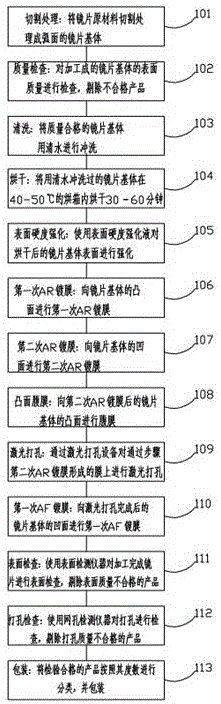

[0058] like figure 1 Described, the manufacturing method of the spectacle lens with mesh described in this embodiment, comprises the following steps:

[0059] 101. Cutting treatment: cutting the raw material of the lens into a curved lens base 14;

[0060] 102. Quality inspection: inspect the surface quality of the processed lens substrate 14, and reject unqualified products;

[0061] 103. Cleaning: Rinse the qualified lens substrate 14 with clean water;

[0062] 104. Drying: drying the lens substrate 14 rinsed with clean water in an oven at 40-50°C for 30-60 minutes;

[0063] 105. Surface hardness strengthening: use surface hardness strengthening liquid to strengthen the surface of the lens base 14 after drying;

[0064] 106. The first AR coating: perform the first AR coating on the convex surface of the lens base 14;

[0065] 107. The second AR coating: the second AR coating is applied to the concave surface of the lens base 14;

[0066] 108. Convex peritoneum: perform ...

Embodiment 2

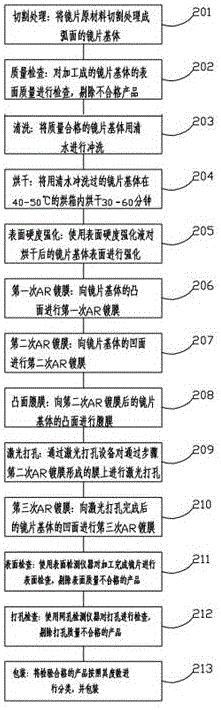

[0075] like image 3 Shown, another kind of manufacturing method of the spectacle lens with mesh described in this embodiment comprises the following steps:

[0076] 201. Cutting treatment: cutting the raw material of the lens into a curved lens base 24;

[0077] 202. Quality inspection: inspect the surface quality of the processed lens substrate 24, and reject unqualified products;

[0078] 203. Cleaning: Rinse the qualified lens substrate 24 with clean water;

[0079] 204. drying: drying the lens substrate 24 rinsed with clear water in an oven at 40-50°C for 30-60 minutes;

[0080] 205. Surface hardness strengthening: use surface hardness strengthening liquid to strengthen the surface of the lens matrix 24 after drying;

[0081] 206. The first AR coating: perform the first AR coating on the convex surface of the lens base 24;

[0082] 207. The second AR coating: the second AR coating is applied to the concave surface of the lens base 24;

[0083] 208. Convex peritoneum:...

Embodiment 3

[0092] like Figure 5 Shown, another kind of manufacturing method of the spectacle lens with mesh described in this embodiment comprises the following steps:

[0093] 301. Cutting treatment: cutting the raw material of the lens into a curved lens base 33;

[0094] 302. Quality inspection: inspect the surface quality of the processed lens base 33, and reject unqualified products;

[0095] 303. Cleaning: washing the qualified lens base 33 with clean water;

[0096] 304. drying: drying the lens substrate 33 rinsed with clean water in an oven at 40-50°C for 30-60 minutes;

[0097] 305. Surface hardness strengthening: use surface hardness strengthening liquid to strengthen the surface of the lens base 33 after drying;

[0098] 306. Laser drilling: use laser drilling equipment to perform laser drilling on the concave surface after the step of surface hardness strengthening. Specifically, the shape of the drilling can be a linear structure, and the thickness of the line is 0.1 ~ 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com