Removable lithium-ion battery unit free of spot welding, battery module and application thereof

A lithium-ion battery, battery cell technology, applied in battery pack parts, batteries, electrical components, etc., can solve the problems of cumbersome series-parallel process, high cost, environmental pollution, etc., to improve production efficiency and production quality, and simplify production. Craftsmanship, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

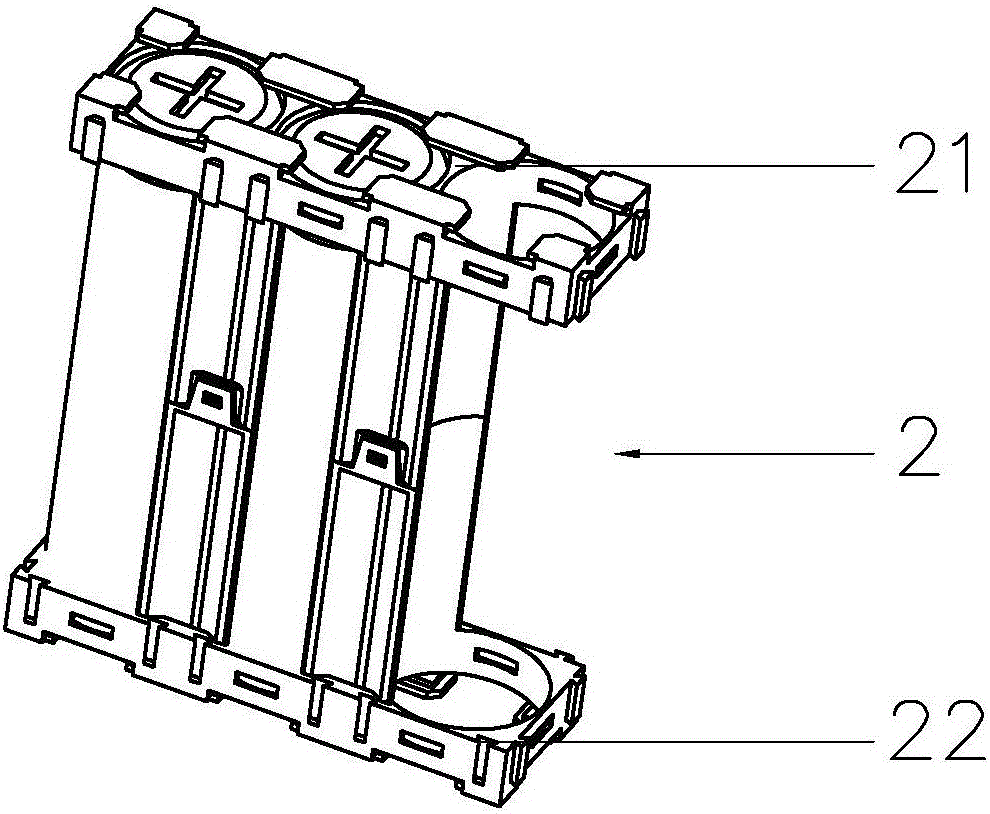

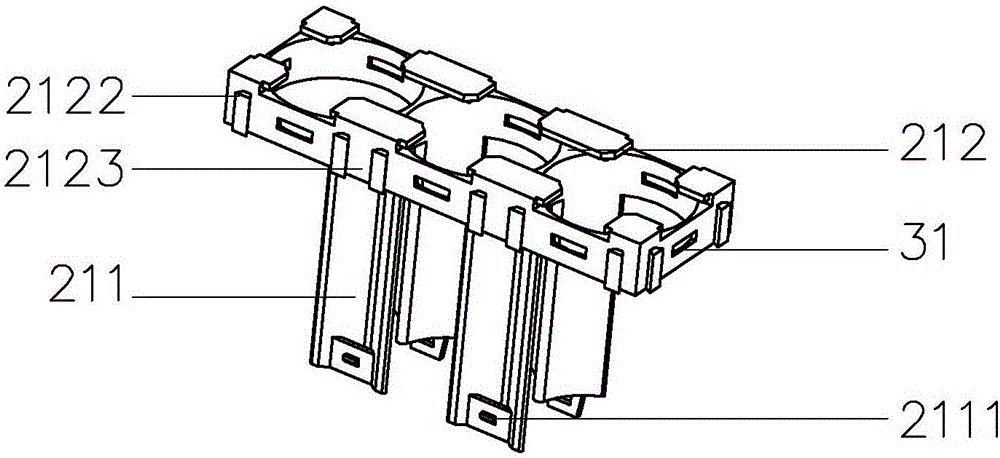

[0089] See Figure 2-5 As shown, a detachable lithium-ion battery unit without spot welding includes a battery 1 and a support 2, and the battery 1 is installed in the support 2 without loosening and detachable; the contact between the battery 1 and the support 2 is guaranteed without loosening It is tight enough that the resistance and current will not change due to the loosening of the battery 1. It is safe and reliable. The installation method is detachable, easy to operate, and does not require spot welding. The bracket 2 can be installed with 2n batteries 1, where n is positive Integer, when an even number of batteries 1 needs to be installed, the scheme of installing 2n batteries 1 is adopted; the bracket 2 can be installed with 2n+1 batteries 1, when an odd number of batteries 1 needs to be installed, 2n+1 batteries 1 are installed The scheme of battery 1, where n is a positive integer.

[0090] The bracket 2 in this embodiment includes a positive mounting part 21 and ...

specific Embodiment approach 2

[0093] See Figure 6-7 As shown, the difference between this embodiment and specific embodiment 1 lies in the structure of the bracket 2,

[0094] The support 2 is composed of an upper top plate 23, a lower bottom plate 24, a side plate 25, a rear side plate 26, and a front cover plate 27. It forms a storage space for the battery 1 and protects the battery 1 from damage on three sides. The battery 1 is not loose after being installed. The upper top plate 23 and the lower bottom plate 24 are provided with corresponding guide grooves 31 for the metal connecting pieces in the longitudinal and transverse directions. The periphery of the upper top plate 23 is provided with clips 231 and fasteners 232 , and the periphery of the lower bottom plate 24 is also provided with fasteners 241 and fasteners 242 for connecting and assembling with another battery unit. The side panels 25 , the rear side panels 26 and the front cover 27 are all provided with hollow areas, which can effectivel...

specific Embodiment approach 3

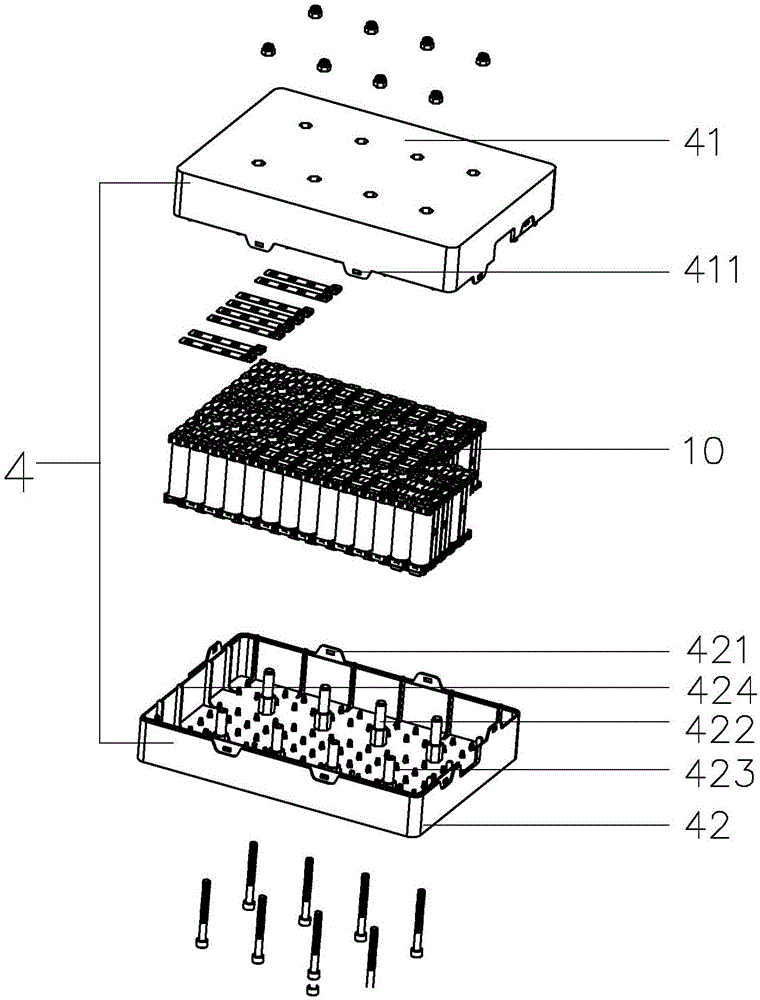

[0096] See Figure 1-5 As shown, in this embodiment, a spot-welding-free detachable lithium-ion battery module that can be flexibly disassembled and assembled includes a number of battery units 10 described in Embodiment 1, and the battery units 10 are detachably assembled through activities. , the assembly direction of the battery unit 10 is the three-dimensional X-axis, Y-axis and Z-axis directions. The assembly direction of this embodiment is the horizontal direction of the X-axis and the vertical assembly of the Y-axis. It also includes a casing 4 for protecting the battery module. The battery module is accommodated in the casing 4. The casing 4 includes a shell cover 41 and a shell cavity 42, and the shell cover 41 is connected with the shell cavity 42. The shell cover 41 is detachably connected to the shell cavity 42 , and the detachable connection includes snap joints, screw joints and hinge joints. The two symmetrical sides of the shell cover 41 are symmetrically pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com