Method of wafer scale fabrication and assembly of a liquid crystal electro-optic device

An electro-optical device, liquid crystal technology, applied in chemical instruments and methods, optics, liquid crystal materials, etc., can solve problems such as pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The above problems can be solved according to the proposed solution, where:

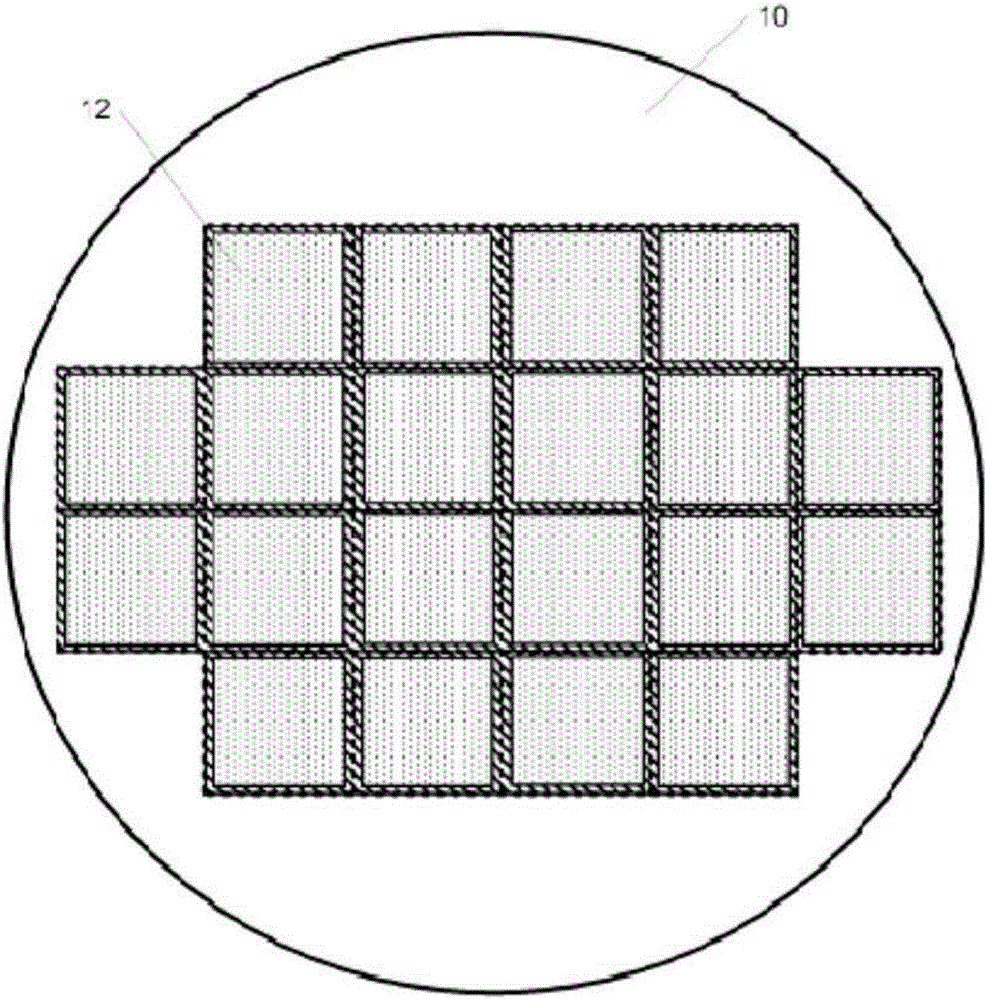

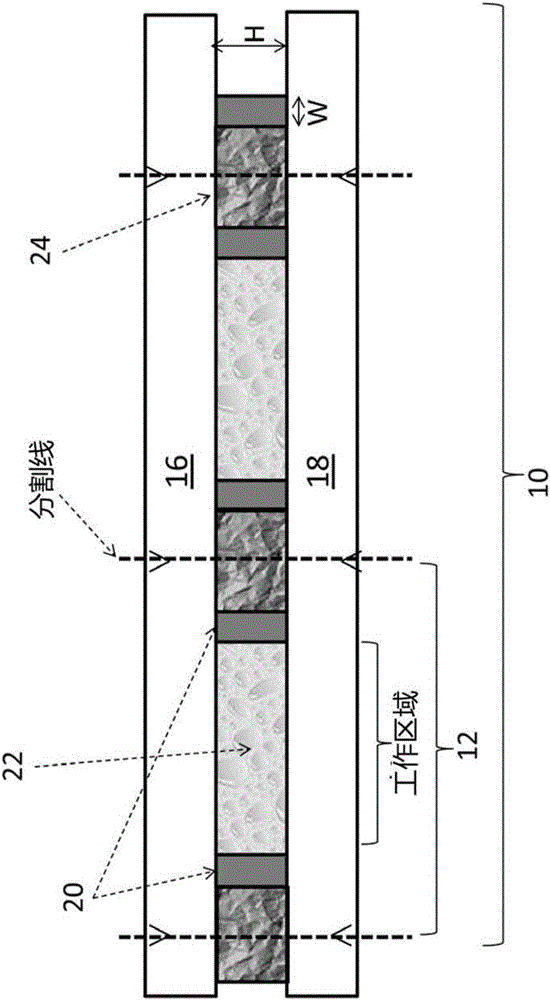

[0031] The fabrication of LCL optics is delicate and, in particular, more complex than fabrication of conventional all-solid-state integrated circuits. Referring to Fig. 1, an LCL wafer 10 is a 2D array of several thousand LCL optical devices 12, which, due to the liquid nature of the LC layer(s) employed, must contain a large number of liquid reservoirs. In the context of this patent application, "wafer" may refer to a substrate of any shape (eg round, rectangular, etc.) and of any type (eg glass, silicon, sapphire).

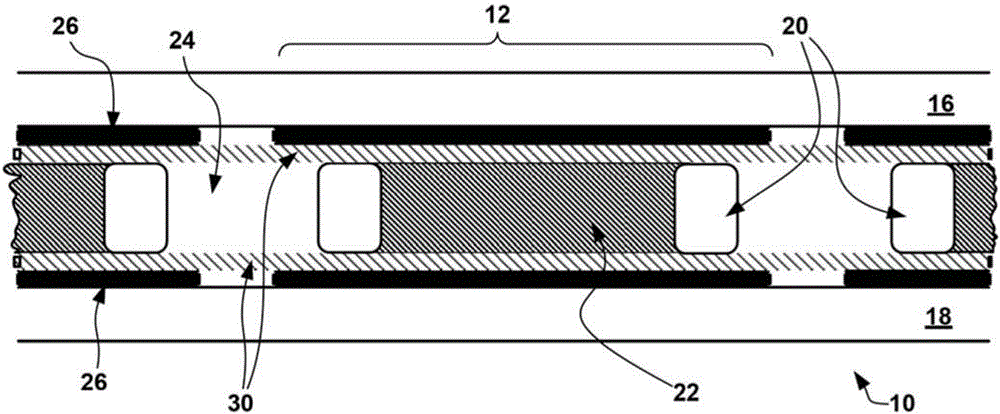

[0032] For simplicity of illustration, the LC material is birefringent and the figures show polarization-dependent LCL optics (one layer of LC on a single wafer). For example, referring to FIG. 2, each final (cut from wafer) LCL optical device 12 includes a substrate 16, 18, and an LC reservoir 22 containing a working fluid separated by a (viscous) reservoir wall 20 which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com