Flotation composite inhibitor for inhibiting pyrite under low alkalinity and using method thereof

A compound inhibitor and pyrite technology, applied in flotation, solid separation, etc., can solve the problems of large CaO consumption, loss, and low gold recovery rate, so as to improve the effective utilization rate, reduce the activation effect, and improve economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The consumption of suppressor of the present invention is to add by relative to raw ore 1.5Kg / t:

[0032] CaO 79.5%

[0033] NaClO 17.0%

[0034] Sodium Humate 3.5%

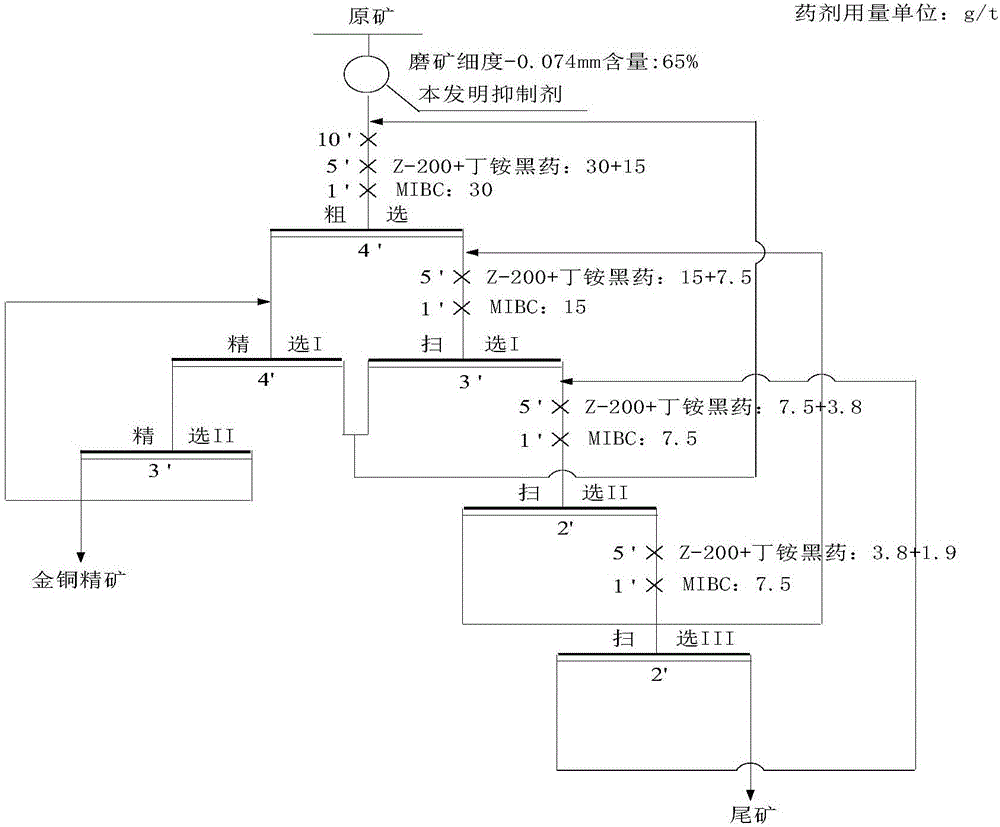

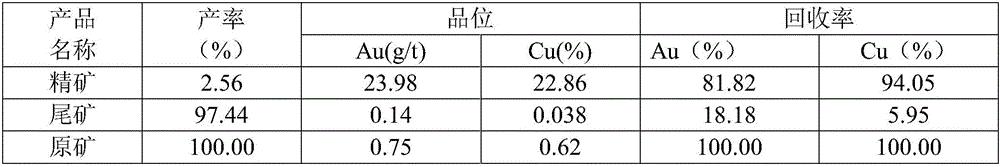

[0035] Attached figure 1 Procedures for closed circuit flotation test results:

[0036]

Embodiment 2

[0038] The consumption of suppressor of the present invention is to add by relative to raw ore 2.0Kg / t:

[0039] CaO 75%

[0040] NaClO 25%

[0041] Sodium Humate 4%

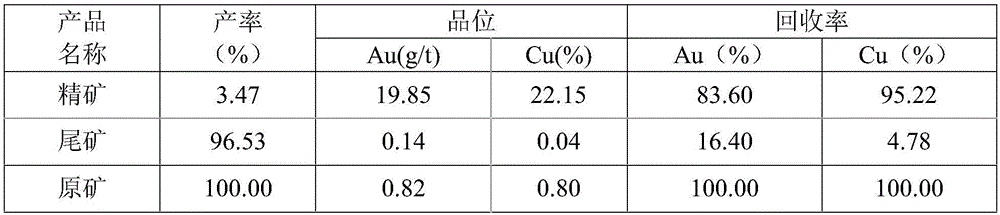

[0042] Attached figure 1 Procedures for closed circuit flotation test results:

[0043]

Embodiment 3

[0045] The consumption of suppressor of the present invention is to add by relative to raw ore 2.0Kg / t:

[0046] CaO 80%

[0047] NaClO 15%

[0048] Sodium Humate 5%

[0049] Attached figure 1 Procedures for closed circuit flotation test results:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com