No-cable electrical system of micro integrated aircraft

An electrical system and aircraft technology, which is applied in the directions of aircraft, aerospace aircraft, and aerospace aircraft guidance devices, etc., can solve the difficulty of aircraft assembly and overall measurement, the increase in the number and weight of cables, and the difficulty in cable routing and layout. problems, to achieve the effect of reducing repetitive functional equipment configuration, improving space utilization, and improving the efficiency of final assembly and testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

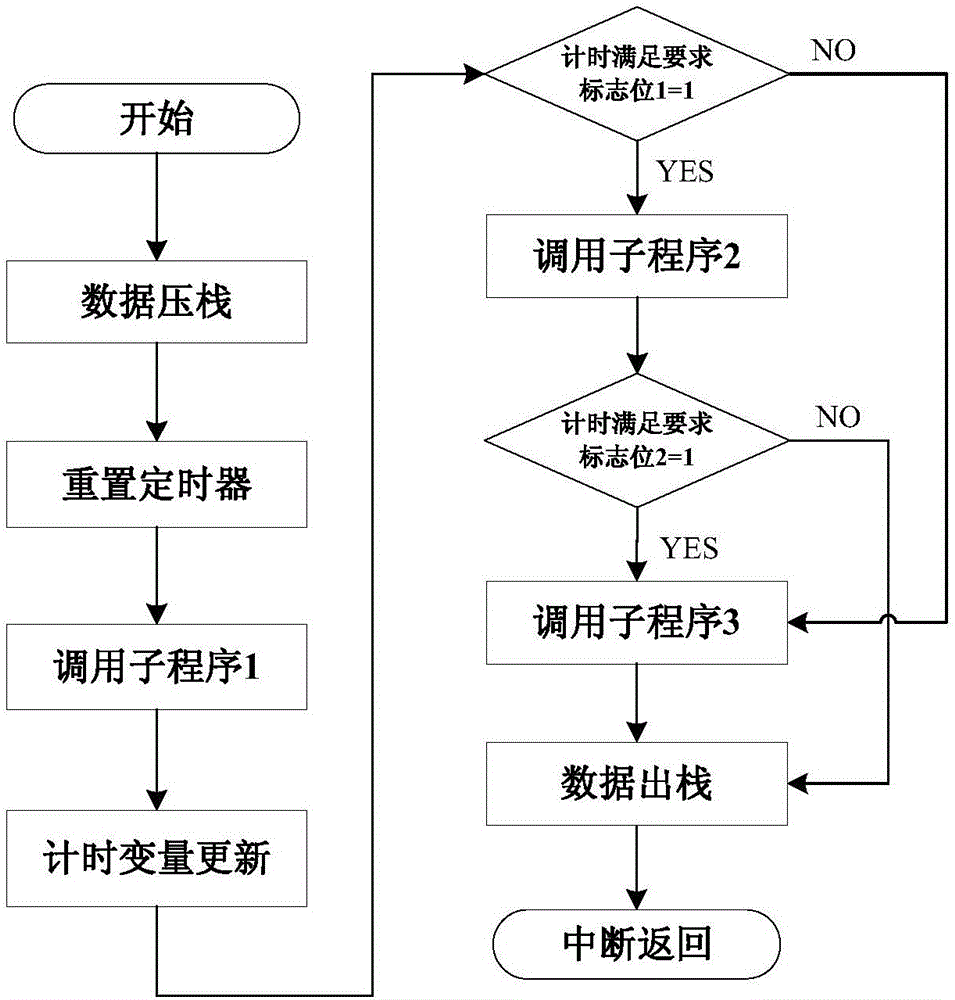

[0048] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

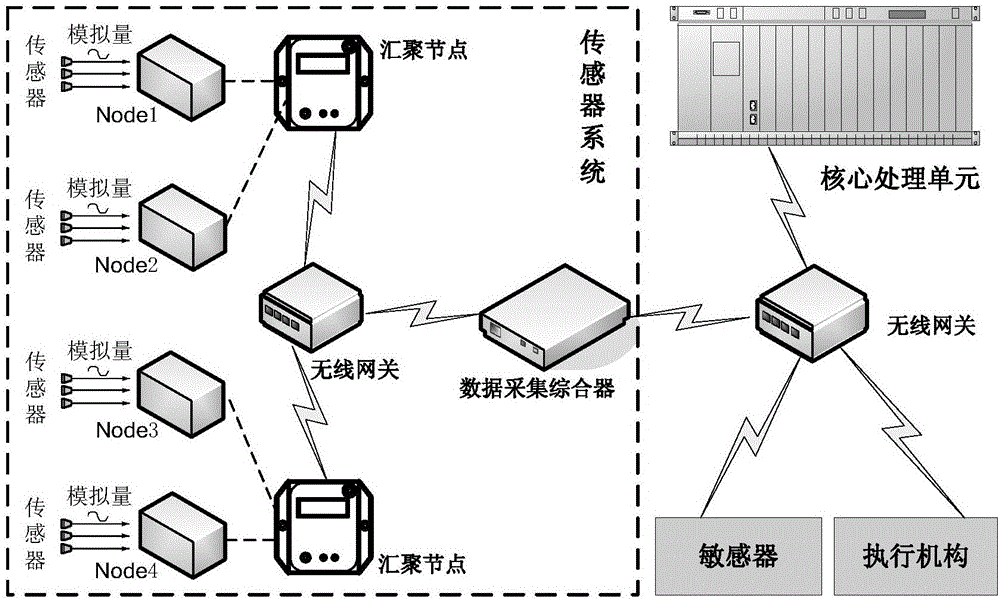

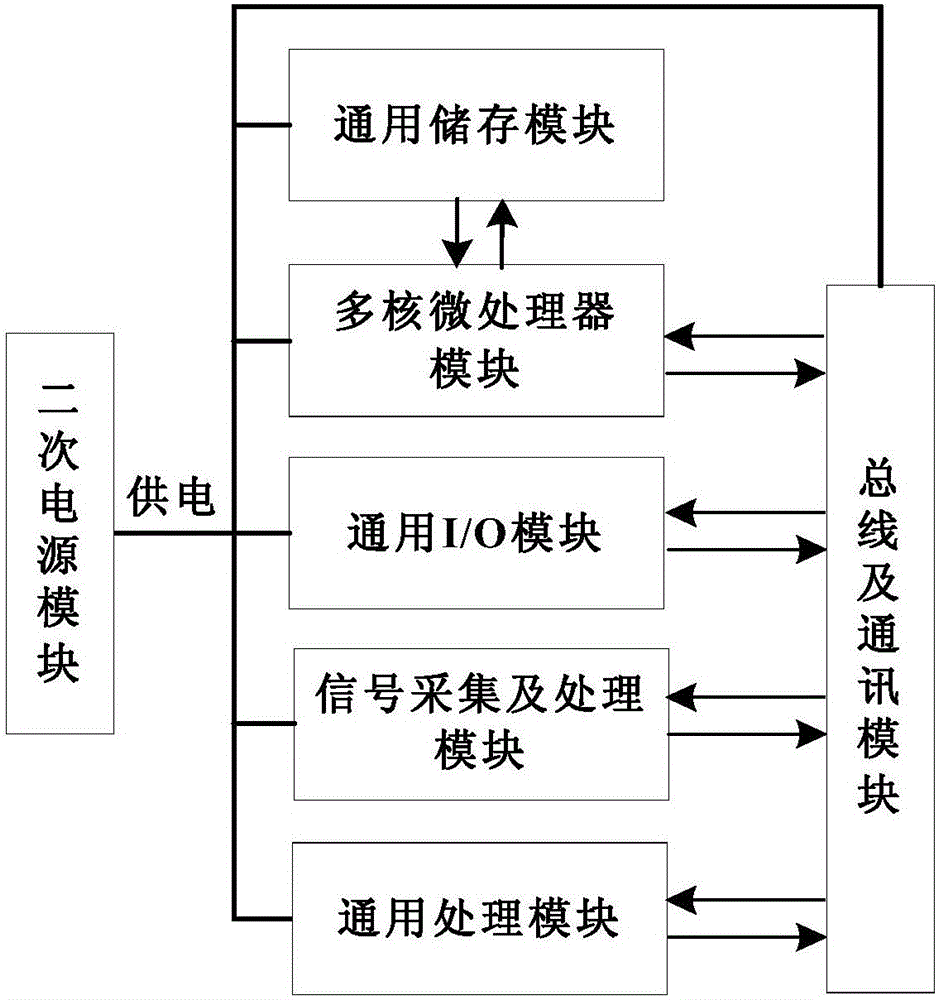

[0049] like figure 1 Shown is a structural diagram of the electrical system of the present invention, from which it can be seen that the micro-integrated aircraft cableless electrical system of the present invention includes a core processing unit, a sensor system, a sensor, an actuator and a wireless ad hoc network.

[0050] Wherein the core processing unit collects aircraft attitude angle, attitude angular velocity, altitude and acceleration signals from the sensor, and after analog-to-digital conversion of the signals, calculates the current position, trajectory and attitude information of the aircraft, and then according to the target position and trajectory of the aircraft, and the attitude information to obtain the control command of the executive agency, and send the control command of the executive agency to the executive agenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com