Method for synthesizing mesoporous carbon material

A synthesis method and mesoporous carbon technology, applied in the preparation/purification of carbon, can solve the problems of waste of raw materials, difficult recovery of organic solvents, environmental pollution, etc., and achieve the effect of accelerating the volatilization rate and avoiding the difficulty of solvent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 0.8g of F127 to 40g of deionized water and stir to dissolve, then add 4.0g of water-soluble phenolic resin to the solution, stir to dissolve at 40°C, continue to stir for 1h, pour the solution into an enamel tray, put it in a vacuum oven, and put it in a vacuum oven at 70 After vacuuming and evaporating the water solvent at ℃ for 10h, heat at normal pressure and 150℃ for 10h for further thermal polymerization, and then heat up and roast in a tube furnace under the protection of nitrogen at a heating rate of 1℃ / min. 3h, kept at 600°C for 2h to obtain ordered mesoporous carbon with a pore diameter of 3.2nm and a specific surface area of 620m 2 / g, pore volume 0.482cm 3 / g.

Embodiment 2

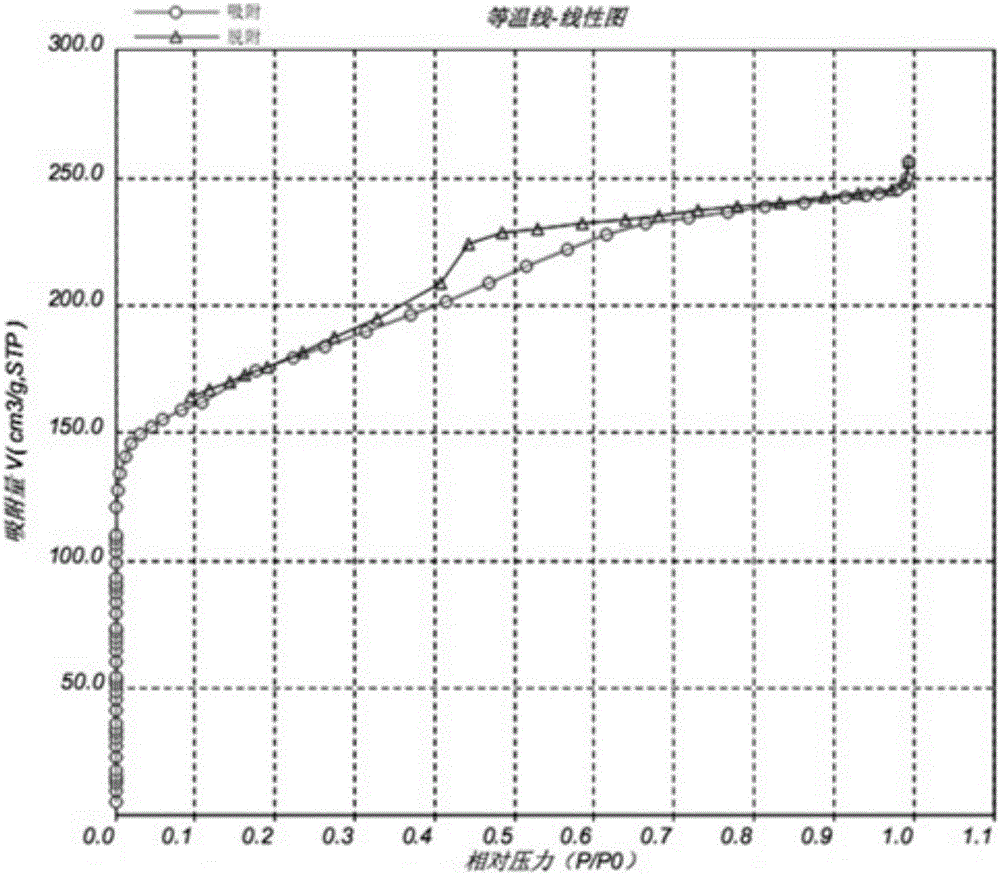

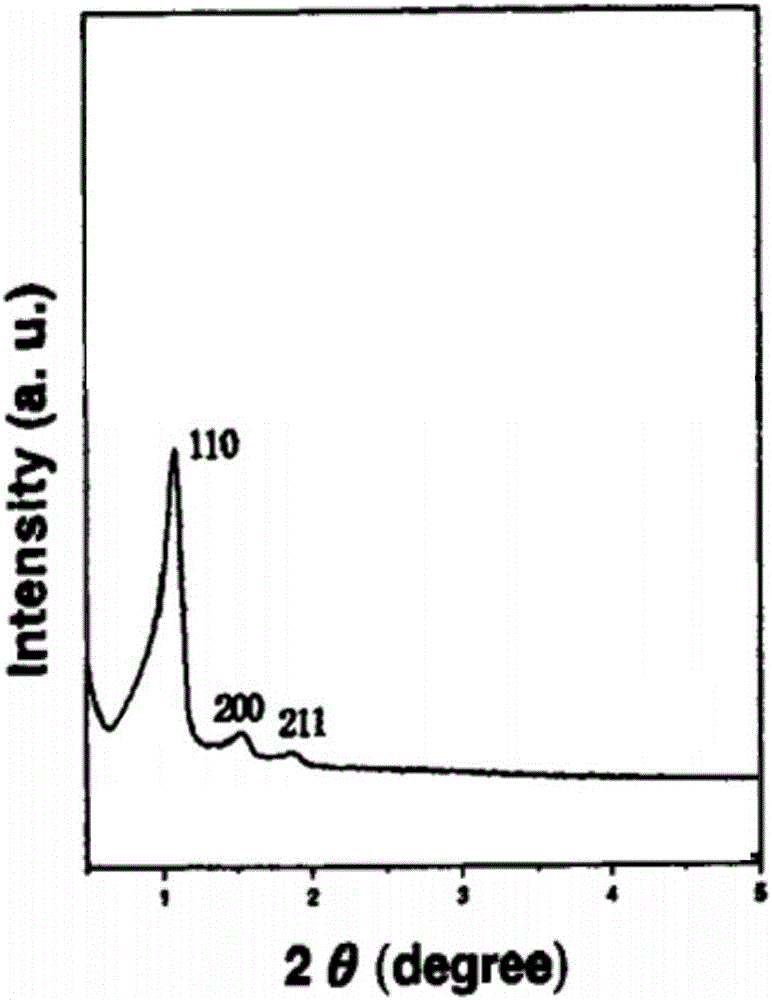

[0024] Add 1.5g of F127 and 0.5g of P123 into 100g of deionized water and stir to dissolve, then add 5.0g of soluble phenolic resin to the solution, stir and dissolve at 30°C to obtain a transparent solution, continue stirring for 0.5h, pour the solution into an enamel tray, and place In a vacuum oven, vacuum evaporate the water solvent at 25°C for 15h, heat at 100°C for 36h at normal pressure for further thermal polymerization, and then heat up and roast in a tube furnace under the protection of nitrogen. The heating rate is 2°C / min. Keep at 450°C for 3h and at 800°C for 2h to obtain ordered mesoporous carbon with a pore size of 3.6nm and a specific surface area of 630m 2 / g, pore volume 0.571cm 3 / g. Such as figure 1 The adsorption-desorption isotherm in is type Ⅳ with a hysteresis loop, indicating that the obtained sample is a mesoporous material. Such as figure 2 As shown in the small-angle XRD pattern of the prepared mesoporous carbon sample, there are three obviou...

Embodiment 3

[0026] Add 1.0g of P123 to 100g of deionized water and stir to dissolve, then add 0.5g of furan resin to the solution, stir and dissolve at 30°C to obtain a transparent solution, continue to stir for 0.5h, pour the solution into an enamel tray, and place it in a vacuum oven. After evaporating the water solvent at 60°C for 10h, heat at 80°C for 60h at normal pressure for further thermal polymerization, and then heat up and roast in a tube furnace under the protection of nitrogen. The heating rate is 2°C / min and kept at 350°C. 3h, kept at 700°C for 3h to obtain ordered mesoporous carbon with a pore size of 3.0nm and a specific surface area of 720m 2 / g, pore volume 0.598cm 3 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com