Flower-like spherical calcium molybdate preparation method

A calcium molybdate, curd-shaped technology, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., to achieve excellent performance, easy access to raw materials, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of flower spherical calcium molybdate, comprising the steps of:

[0021] (1) Take a certain amount of calcium chloride and 0.006g EDTA in a beaker, add an appropriate amount of distilled water, and fully magnetically stir;

[0022] (2) Take a certain amount of sodium molybdate in a beaker, add an appropriate amount of distilled water, and fully magnetically stir;

[0023] (3) Sodium molybdate solution is poured in the beaker that fills calcium chloride solution;

[0024] (4) Continue to magnetically stir the solution for 15 minutes, then move it to an ultrasonic cleaner and ultrasonicate for half an hour;

[0025] (5) The obtained precipitate was washed three times with distilled water and ethanol respectively, and dried in an oven at 60° C. for 6 hours to obtain flower-shaped calcium molybdate.

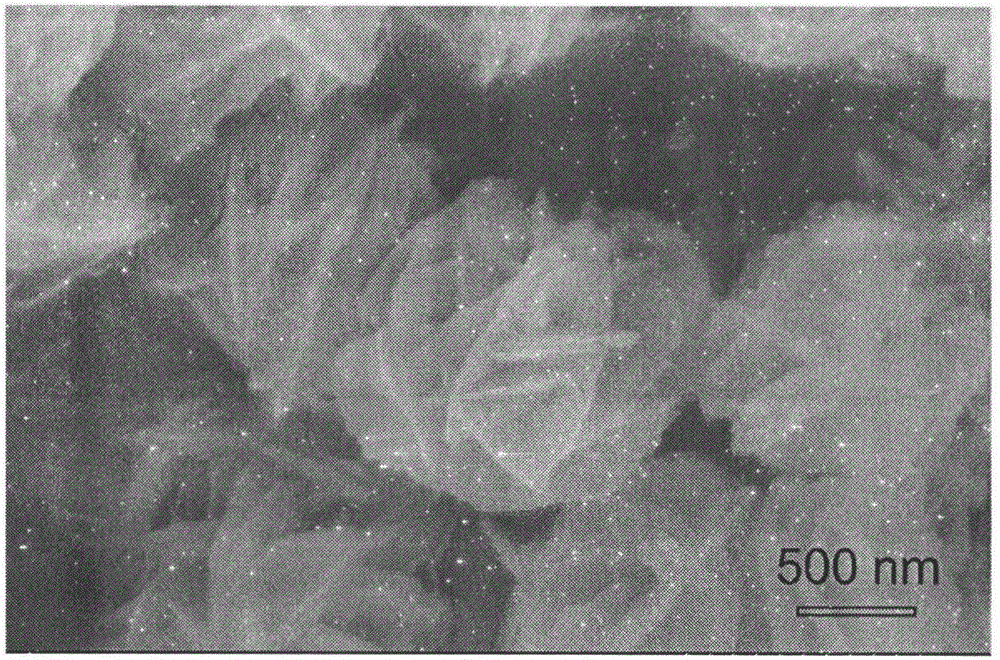

[0026] The prepared product was observed by scanning electron microscope, and the figure 1 It can be seen that the obtained calcium molybdate is in the...

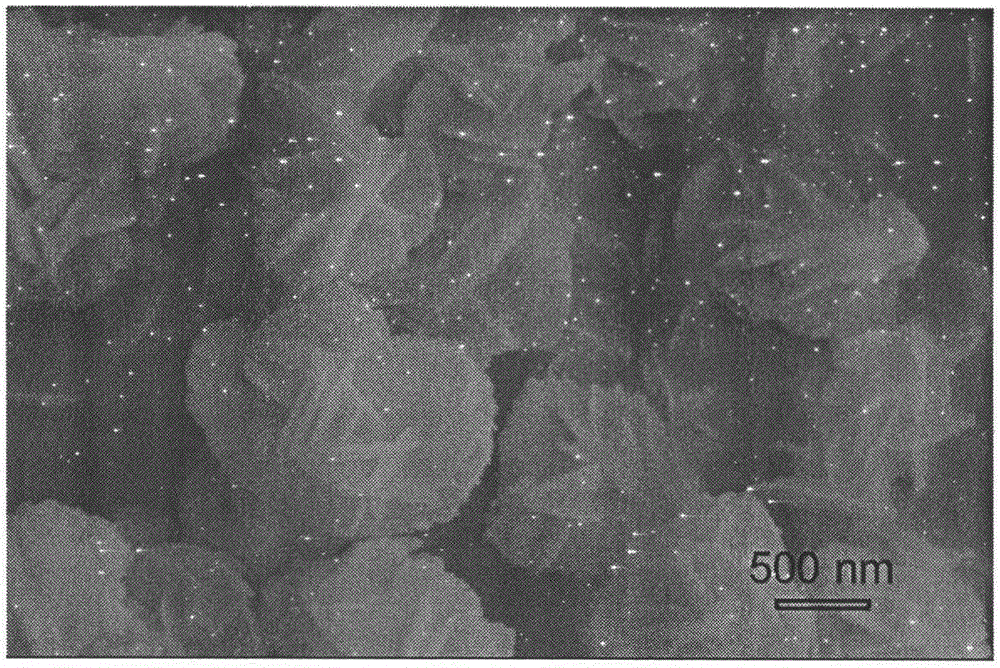

Embodiment 2

[0028] A preparation method of flower spherical calcium molybdate, comprising the steps of:

[0029] (1) Take a certain amount of calcium chloride and 0g EDTA in a beaker, add an appropriate amount of distilled water, and fully magnetically stir;

[0030] (2) Take a certain amount of sodium molybdate in a beaker, add an appropriate amount of distilled water, and fully magnetically stir;

[0031] (3) Sodium molybdate solution is poured in the beaker that fills calcium chloride solution;

[0032] (4) Continue to magnetically stir the solution for 15 minutes, then move it to an ultrasonic cleaner and ultrasonicate for half an hour;

[0033] (5) The obtained precipitate was washed three times with distilled water and ethanol respectively, and dried in an oven at 60° C. for 6 hours to obtain flower-shaped calcium molybdate.

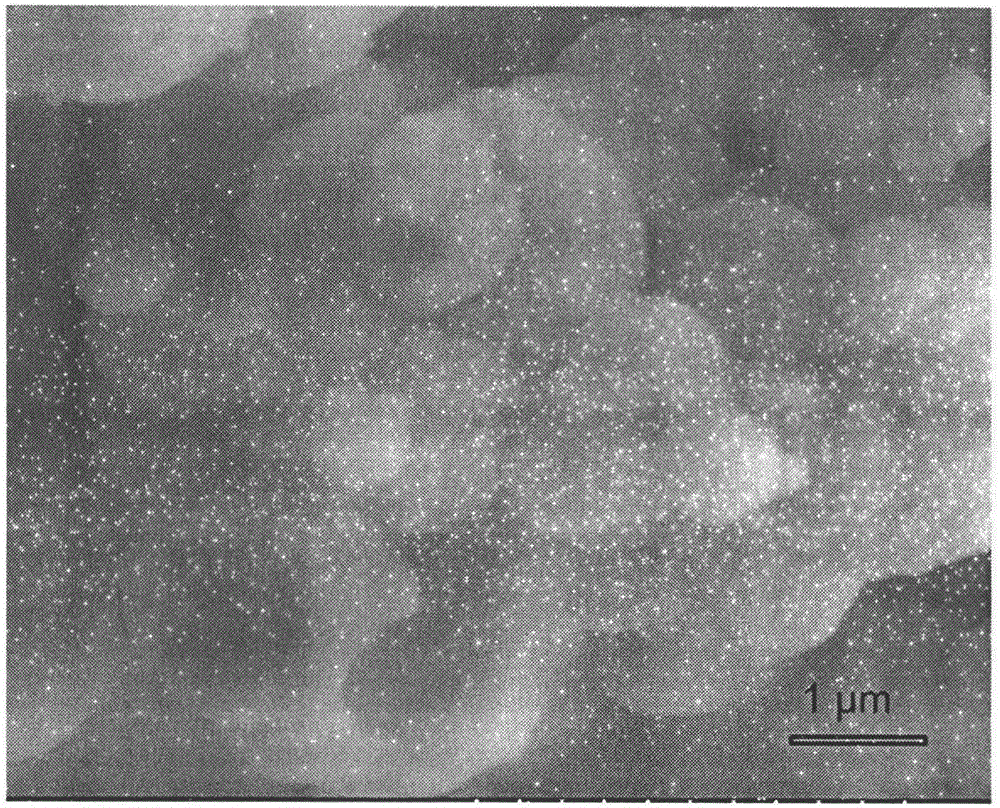

Embodiment 3

[0035] A preparation method of flower spherical calcium molybdate, comprising the steps of:

[0036] (1) Weigh a certain amount of calcium chloride and 0.012g EDTA in a beaker, add an appropriate amount of distilled water, and fully magnetically stir;

[0037] (2) Take a certain amount of sodium molybdate in a beaker, add an appropriate amount of distilled water, and fully magnetically stir;

[0038] (3) Sodium molybdate solution is poured in the beaker that fills calcium chloride solution;

[0039] (4) Continue to magnetically stir the solution for 15 minutes, then move it to an ultrasonic cleaner and ultrasonicate for half an hour;

[0040] (5) The obtained precipitate was washed three times with distilled water and ethanol respectively, and dried in an oven at 60° C. for 6 hours to obtain flower-shaped calcium molybdate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com