Stain-resistant pure acrylic natural stone paint emulsion and preparation method thereof

A real stone paint, pure acrylic technology, applied in the direction of biocide-containing paint, antifouling/underwater paint, coating, etc. Excellent hydrophobicity, preventing adhesion to the surface of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

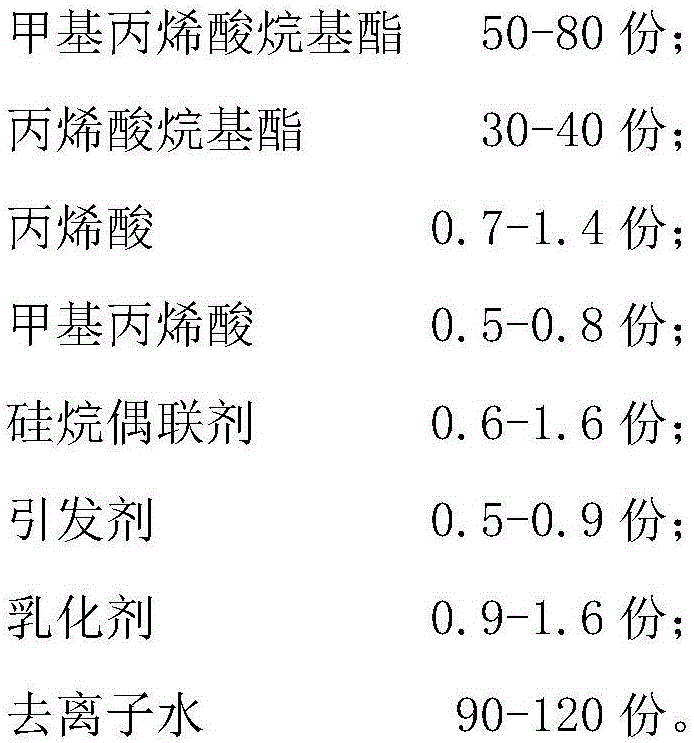

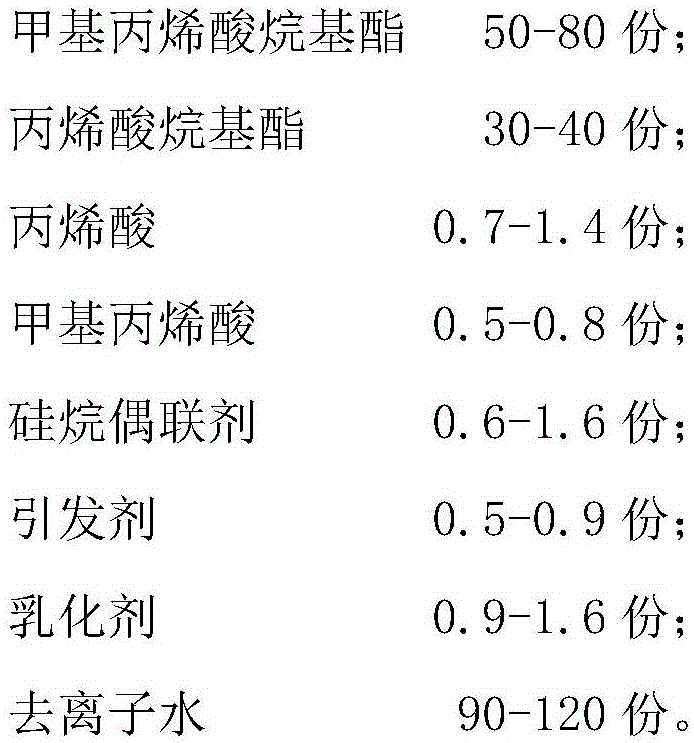

Method used

Image

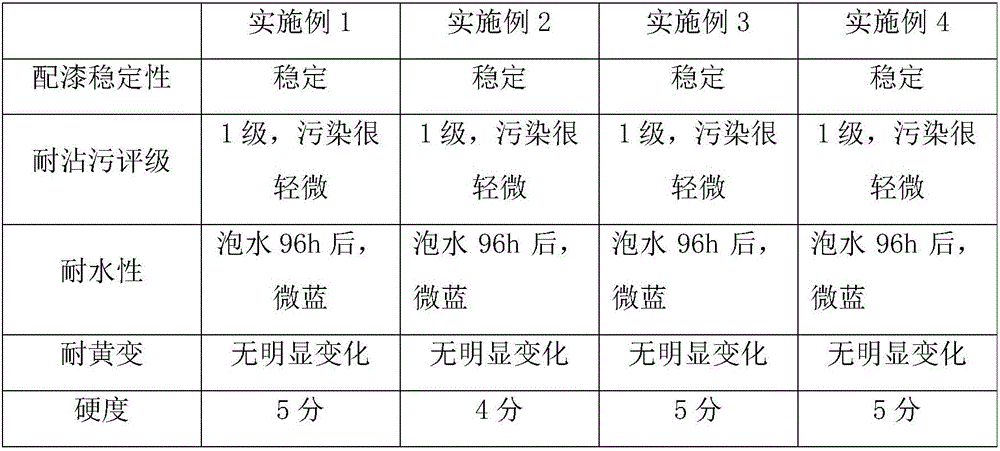

Examples

Embodiment 1

[0028] A stain-resistant pure acrylic real stone paint emulsion, its raw material composition includes the following components in parts by weight: 59.3 parts of methyl methacrylate, 5 parts of n-butyl methacrylate, 34.7 parts of n-butyl acrylate, 1.0 part of acrylic acid, 0.5 parts of methacrylic acid, 1.0 parts of vinyltrimethoxysilane, 0.7 parts of ammonium persulfate (initiator), 0.95 parts of sodium lauryl sulfate (emulsifier), and 105 parts of deionized water.

[0029] The preparation method of described stain-resistant pure acrylic genuine stone paint emulsion comprises the steps:

[0030] a. Preparation of base material liquid A: Add 35 parts of deionized water and 0.35 parts of sodium lauryl sulfate into a polymerization kettle equipped with a stirrer, condenser, and constant-flow pump feeding device, and raise the temperature until the temperature in the kettle reaches 83 -86°C;

[0031] b. Preparation of pre-emulsion B: Add 40 parts of deionized water, 0.3 parts of...

Embodiment 2

[0036] A stain-resistant pure acrylic real stone paint emulsion, its raw material composition includes the following components in parts by weight: 55.7 parts of methyl methacrylate, 4 parts of n-butyl methacrylate, 39.7 parts of n-butyl acrylate, 1.0 part of acrylic acid, 0.8 parts of methacrylic acid, 1.1 parts of γ-methacryloxypropyl trimethoxysilane, 0.7 parts of sodium persulfate (initiator), 1.2 parts of sodium lauryl sulfate (emulsifier), 105 parts of deionized water share.

[0037] The preparation method of described stain-resistant pure acrylic genuine stone paint emulsion comprises the steps:

[0038] a. Preparation of base material liquid A: Add 40 parts of deionized water and 0.4 parts of sodium lauryl sulfate to a polymerization kettle equipped with a stirrer, condenser, and constant-flow pump feeding device, and heat up until the temperature in the kettle reaches 83 -86°C;

[0039]b. Preparation of pre-emulsion B: Add 35 parts of deionized water, 0.4 parts of s...

Embodiment 3

[0044] A stain-resistant pure acrylic real stone paint emulsion, its raw material composition includes the following components in parts by weight: 52.4 parts of methyl methacrylate, 10 parts of n-butyl methacrylate, 20 parts of n-butyl acrylate, 2-acrylic acid 16.6 parts of ethylhexyl ester, 1.0 parts of acrylic acid, 0.5 parts of methacrylic acid, 1.3 parts of vinyltrimethoxysilane, 0.7 parts of potassium persulfate (initiator), 1.4 parts of sodium lauryl sulfate (emulsifier), and 108 parts of ionized water.

[0045] The preparation method of described stain-resistant pure acrylic genuine stone paint emulsion comprises the steps:

[0046] a. Preparation of base liquid A: Into a polymerization kettle equipped with a stirrer, a condenser, and a constant flow pump feeding device, add 38 parts of deionized water and 0.4 parts of sodium lauryl sulfate, and heat up until the temperature in the kettle reaches 83 -86°C;

[0047] b. Preparation of pre-emulsion B: Add 40 parts of de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com