Method for preparing thallium-based high-temperature superconducting thin film without roasting target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1, preparing a Tl-Ba-Ca-Cu-O amorphous precursor thin film by using DC magnetron sputtering.

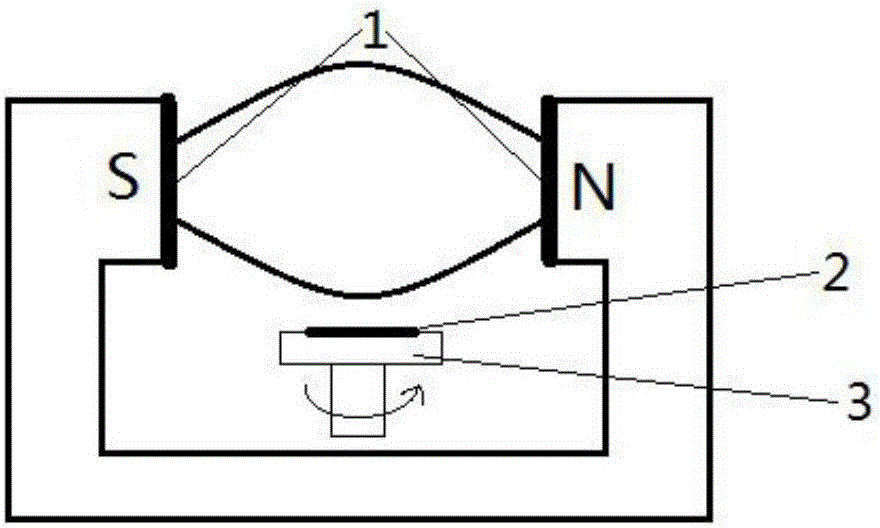

[0023] figure 1 is a schematic diagram of the magnetron sputtering device. In the figure, two sputtering targets 1 are placed symmetrically. The film substrate substrate 2 is placed on a rotatable substrate support 3 (ie, a rotating stage).

[0024] The sputtering target 1 was produced by a two-step method. First use BaO 2 , CaO and CuO are mixed according to the atomic ratio Ba:Ca:Cu=2:1:2. After uniform mixing and grinding, they are burned in a flowing oxygen atmosphere at a temperature of 900°C for 10 hours, and then carefully ground after cooling. Burn again under the same conditions for 10 hours, grind to make BaCaCuO powder, and then mix BaCaCuO powder with Tl 2 o 3 The powders were mixed and grinded carefully, then pressed into tablets, sealed with a crucible, and fired in a flowing oxygen atmosphere at a temperature of 850°C for 1 hour. After cooling, caref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com