A small underground storage tank and its manufacturing method

A manufacturing method and technology of a water storage tank, applied in waterway systems, water supply devices, water conservancy projects, etc., can solve problems such as poor treatment, long construction period, and short service life, so as to avoid external pollution of pool water, short construction period, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

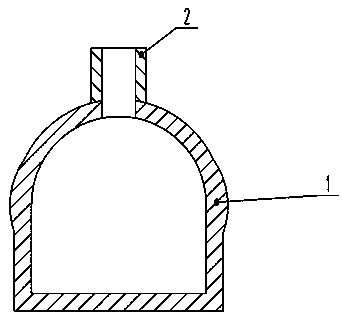

[0041] see figure 1 , in the figure, the small-sized underground storage tank of the present invention includes a pool body 1 and an upper manhole 2, wherein the pool body includes a bottom plate, a pool wall and a top plate, the pool wall is a cylindrical structure, and the top plate is a dome structure; the pool body is One-time pouring of plain concrete to form the structure. The inner diameter of the pool wall is 2m, the depth of the pool wall is 1m, and the height of the pool dome is 1m.

[0042] Further, the concrete for pouring the reservoir can be C20 concrete, and the concrete can be added with a calcium ortho-aluminate expansion agent of 8% by weight of cement. The shrinkage of the concrete can be equally compensated, and it has the function of filling and blocking capillary pores, greatly improving the anti-seepage and anti-cracking ability of the concrete, and the increased cost is small.

[0043] The thickness of the poured concrete is 200mm, and the thickness o...

Embodiment 2

[0045] This embodiment is similar in structure to Embodiment 1, and the same structure will not be repeated here. The difference is that the inner diameter of the reservoir wall in this embodiment is 3m.

Embodiment 3

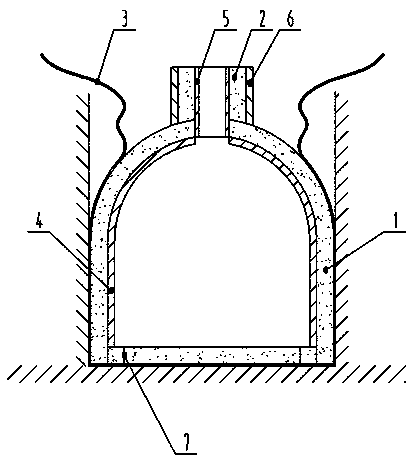

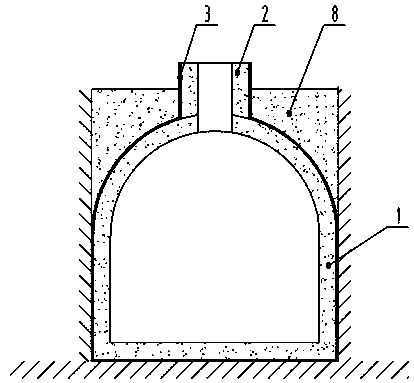

[0047] see Figure 2-3 , among the figure, the present invention is as described in embodiment 1 small-sized underground storage tank manufacturing method, wherein pool body 1 is to use one deck HDPE anti-seepage film 3 covered on the pit wall as the outer formwork, with pool body The combined steel formwork 4 with matching shape is formed by one-time pouring of the inner formwork; the upper manhole 2 is located in the middle of the pool roof and is formed by pouring the inner and outer formworks 5 and 6 of the above manhole; specifically, the following steps are included:

[0048] (1) Make a template:

[0049]The design diameter of the reservoir is 2m, and the size of the formwork vertical and horizontal ribs and formwork panels used in the pool wall and pool top is determined by combining calculation and lofting; the width of each combined formwork in the pool wall is 200mm, and the height is 500mm; The maximum width and length of each combined formwork at the top part are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com