An online monitoring system for comprehensive process parameters of cigarette packets

A technology of comprehensive process and monitoring system, applied in the field of cigarette production, can solve the problems of not easy to integrate into the upper computer system, only the MODBUS protocol, the controller has no communication interface, etc., and achieves a simple structure, intuitive and convenient operation, and convenient information integration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

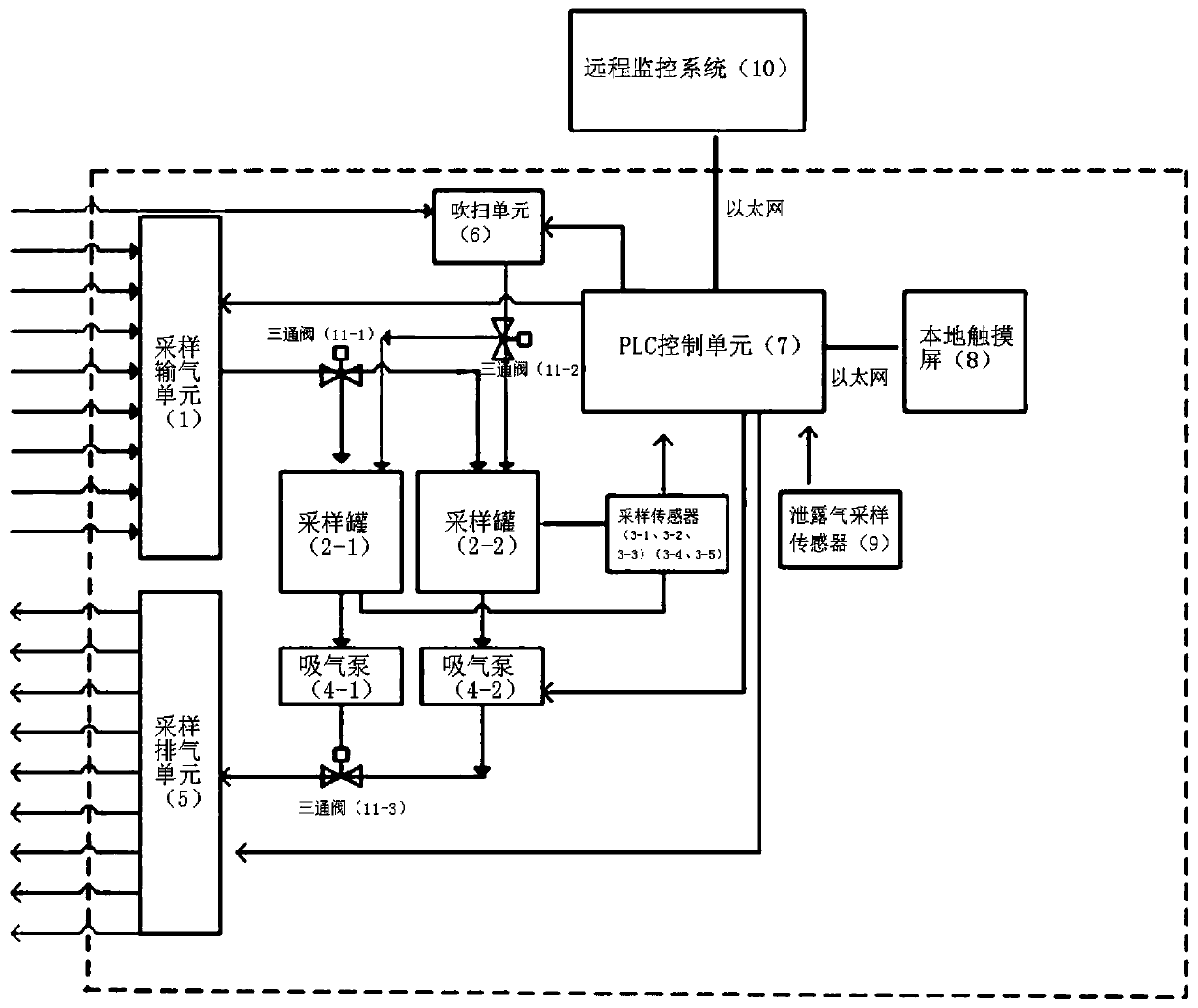

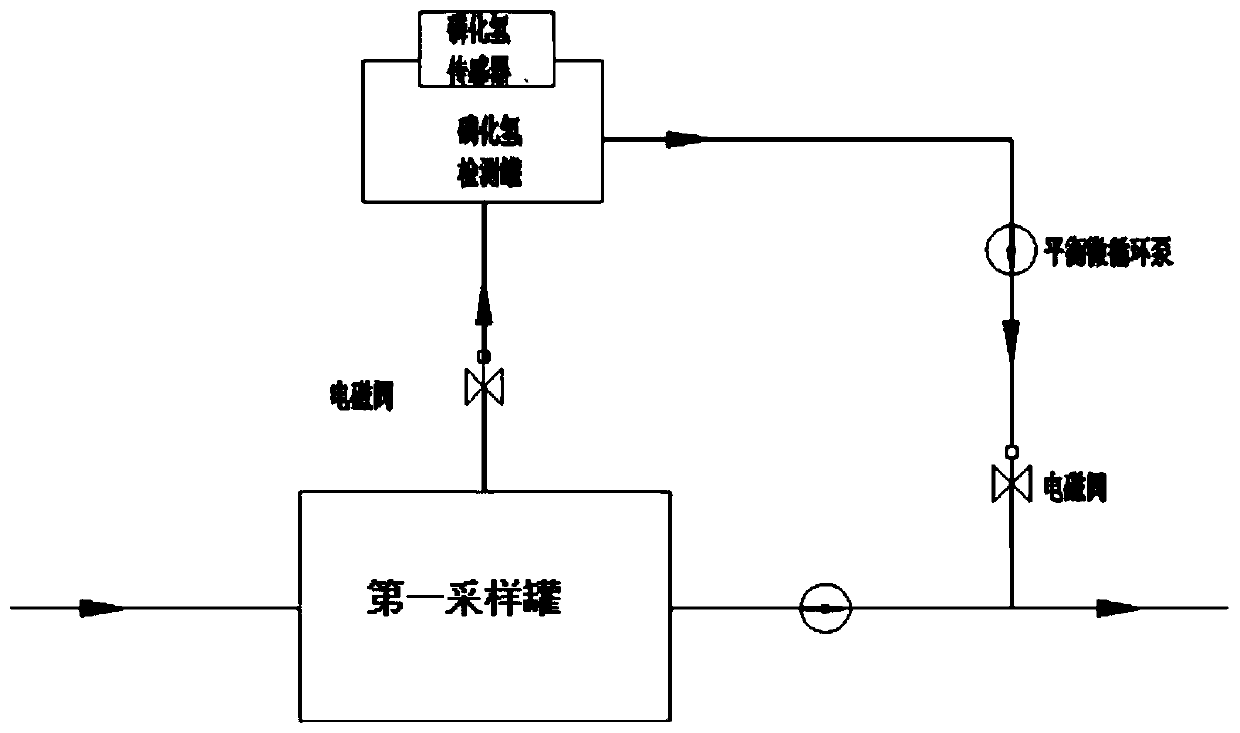

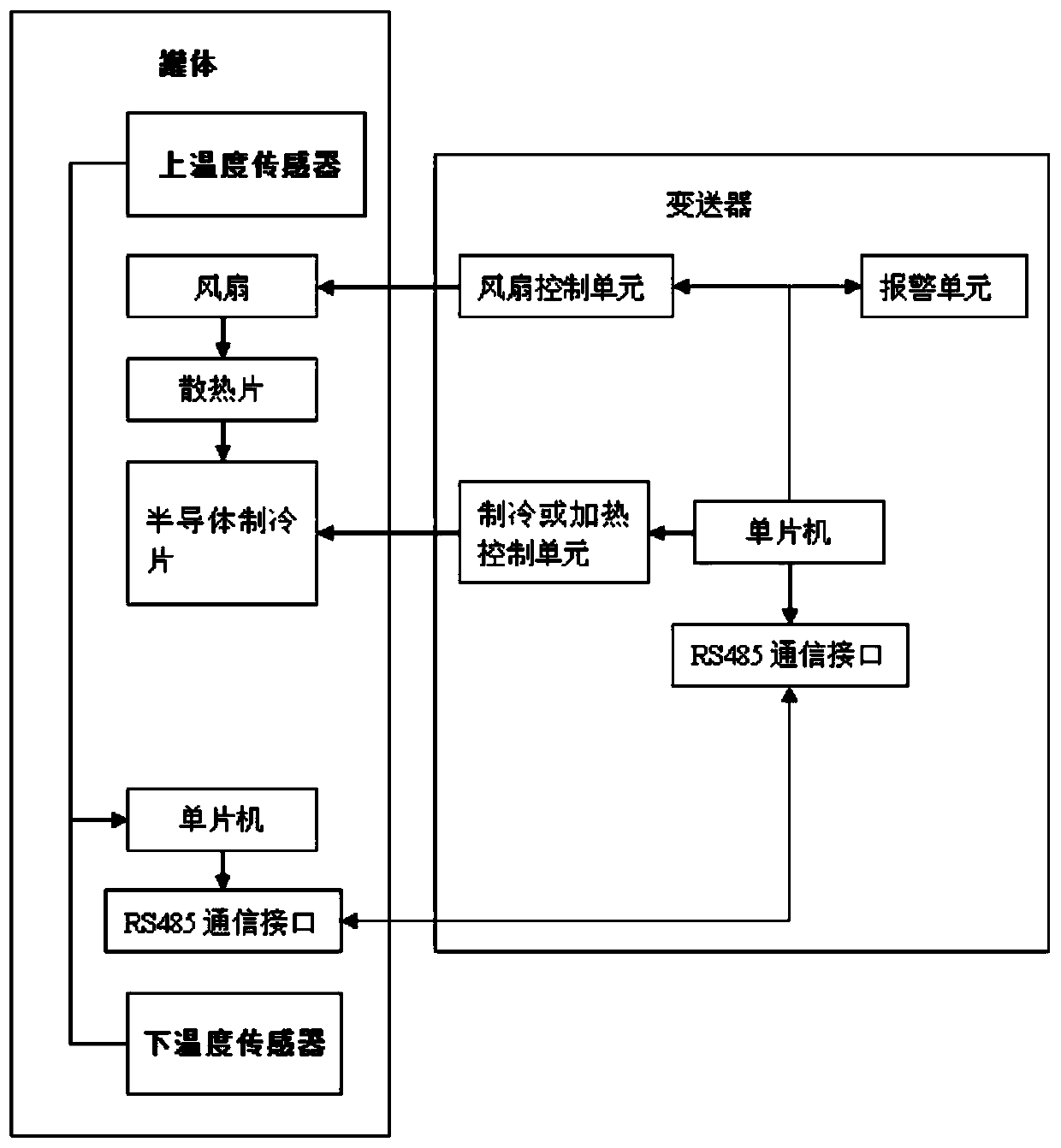

[0026] Such as figure 1 An on-line monitoring system for comprehensive process parameters of cigarette packets is shown, the system includes a gas sampling unit 1, a phosphine monitoring device, a temperature, humidity and oxygen content monitoring device, a purging unit 6, a sampling and exhausting unit 5, and a PLC controller Unit 7, man-machine interface unit 8, phosphine leakage gas sampling sensor 9 and remote monitoring system 10. The sampling conveying unit is provided with 16 connection branches connected to each position of the warehouse respectively. The 16 connection branches are respectively provided with intake solenoid valves, and the intake solenoid valves are connected to the PLC controller unit 7. The terminals of the 16 connection branches are connected to each other. Parts are respectively connected with air i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com