Hemolytic agent, method for pretreatment of biological sample, method for determining content of target substance, and kit

A technology of biological samples and hemolytic agents, applied in the field of analysis, can solve problems that need to be improved, and achieve the effects of overcoming slow detection speed, improving detection efficiency, and promoting immune response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Prepare hemolyzing reagent A for whole blood C-reactive protein detection according to the following formula:

[0099] Triton X-114 8.0g

[0100] Boric acid 5.6g

[0101] Sodium 4-Hydroxyethylpiperazineethanesulfonate 2.5g

[0102] Add deionized water to dissolve, adjust an appropriate amount of NaOH or HCl to 7.0, and add deionized water to a final volume of 1L.

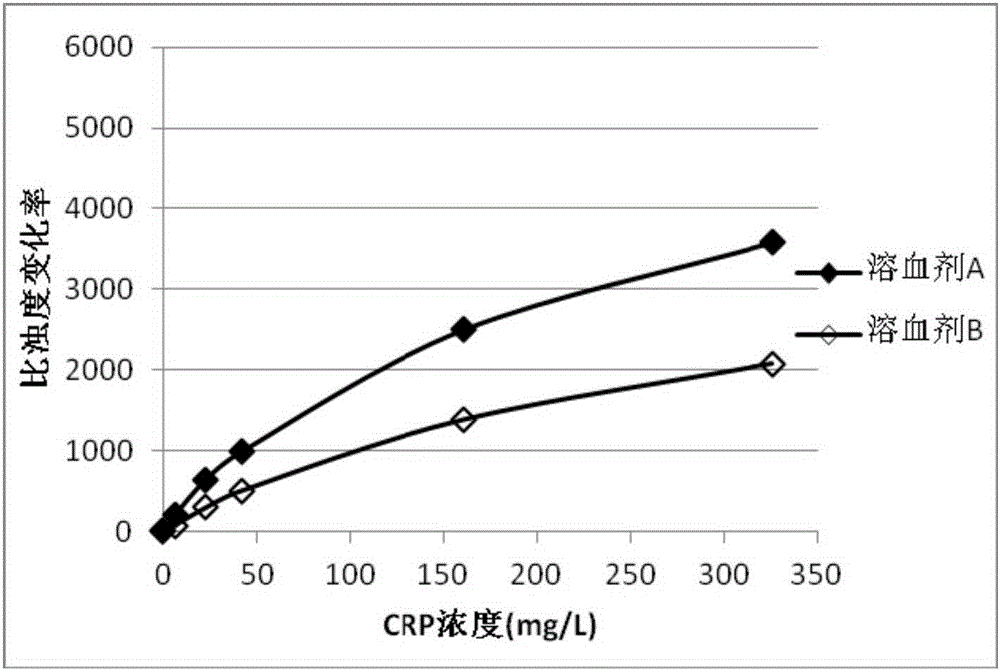

[0103] In this example, 8 microliters of a known concentration of C-reactive protein calibrator (concentration in the range of 0-320 mg / L) was added to 0.2 mL of hemolytic reagent A prepared. Under the condition that the temperature was kept at 37°C, the obtained mixture was allowed to stand for hemolysis for 90 seconds, and then 0.2 mL of C-reactive protein immunoassay reagent was added to the mixture, and after mixing, the change of the absorbance signal at 850 nm was measured to calculate the immunoassay. The change rate of turbidity (also referred to as "reactivity") ΔA=(A2-A1) / (T2-T1) from the 30th se...

Embodiment 2

[0115] Prepare hemolyzing reagent C for whole blood C-reactive protein detection according to the following formula:

[0116] Lauryl dimethyl betaine 0.05g

[0117] Boric acid 5.6g

[0118] Sodium 4-Hydroxyethylpiperazineethanesulfonate 2.5g

[0119] Dissolve the above components with deionized water, adjust to 7.0 with an appropriate amount of NaOH or HCl, and then add deionized water to a final volume of 1 L.

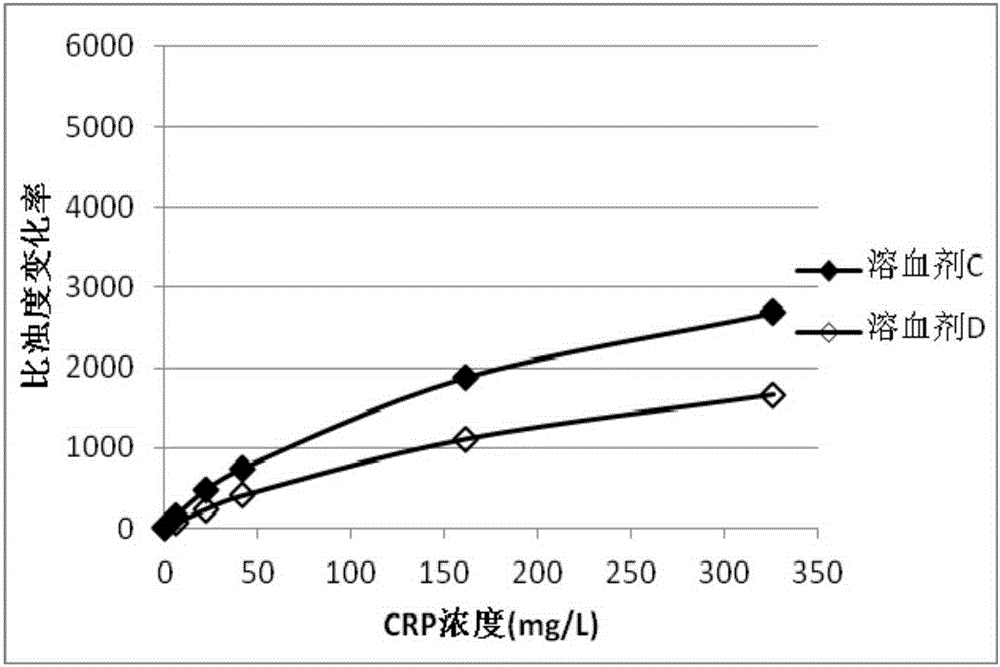

[0120] According to the method substantially the same as Example 1, the standard curve of hemolytic agent C is established, the difference is only that the hemolytic agent A in Example 1 is replaced by hemolytic agent C, and the standard curve of hemolytic agent C is shown in figure 2 middle.

Embodiment 3

[0130] Prepare hemolyzing reagent E for whole blood C-reactive protein detection according to the following formula:

[0131] Saponin 4.0g

[0132] Boric acid 5.6g

[0133] Sodium 4-Hydroxyethylpiperazineethanesulfonate 2.5g

[0134] Dissolve the above components with deionized water, adjust to 7.0 with an appropriate amount of NaOH or HCl, and then add deionized water to a final volume of 1 L.

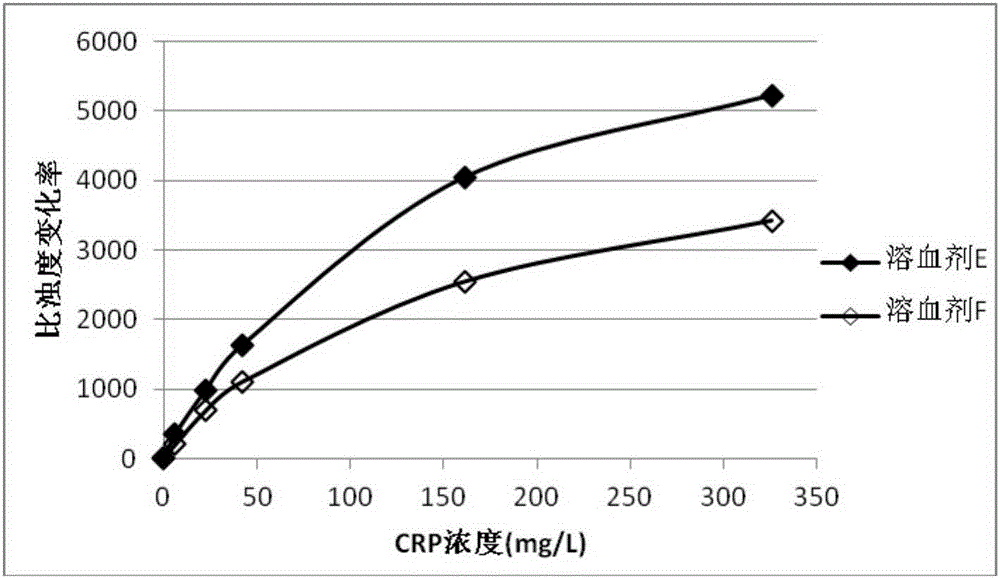

[0135] According to the method basically the same as Example 1, establish the standard curve of hemolyzing agent E, the only difference is that the hemolyzing agent A in Example 1 is replaced by hemolyzing agent E, and the time of standing hemolysis after mixing the hemolyzing agent and the sample is shortened for 30 sec, the standard curve of Lysing Reagent E is shown in image 3 middle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com