Miniaturized high-performance microstrip filtering power divider based on zero-order resonator

A zero-order resonance, microstrip filtering technology, applied in waveguide-type devices, circuits, connecting devices, etc., can solve problems such as unfavorable engineering applications, increased cost, unsatisfactory size and performance of filter power dividers, and easy processing. , low cost and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

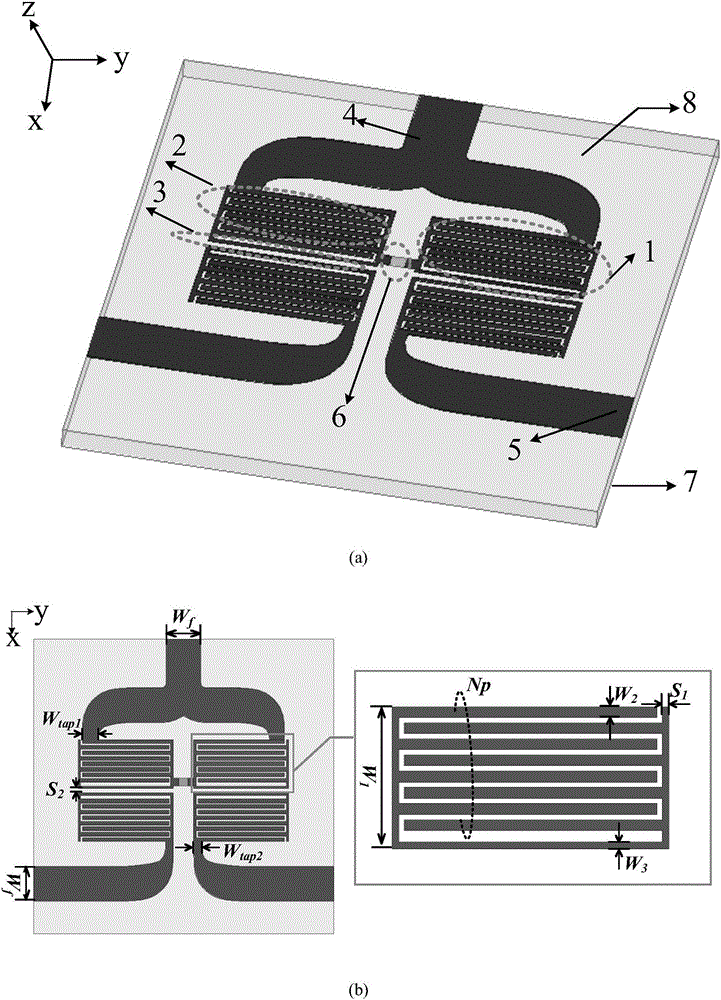

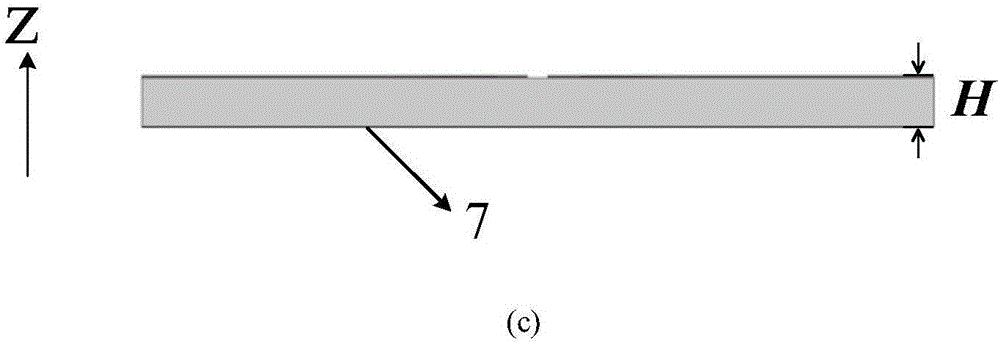

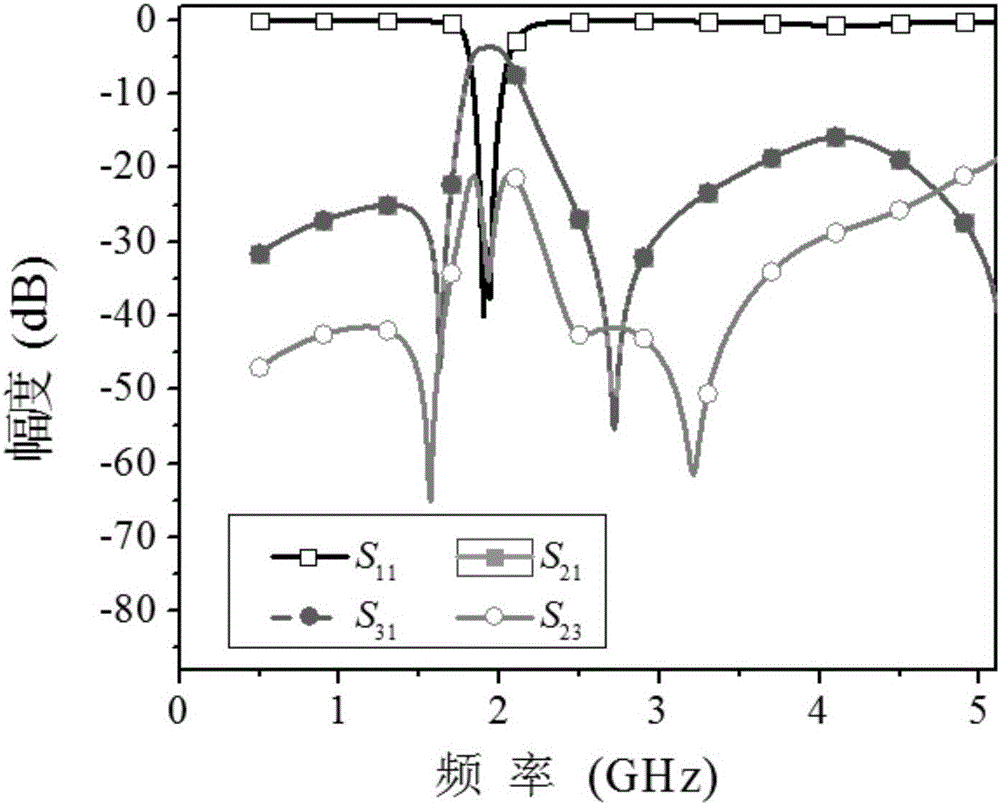

[0023] combine figure 1 , the zero-order resonator-based miniaturized high-performance microstrip filter power divider has four identical zero-order resonant units 1, upper port feeder 4, lower port feeder 5, isolation resistor 6, metal floor 7 and dielectric substrate 8, The upper port feeder 4, the lower port feeder 5, the isolation resistor 6 and the four zero-order resonant units 1 are all printed on the upper surface of the dielectric substrate 8, and a metal floor 7 is arranged below the dielectric substrate 8, and the lower port feeder 5 The number is two, and the two lower port feeders are located on both sides of the lower part of the microstrip filter power divider and are symmetrical about the central axis. The four zero-order resonant units 1 are distributed in a 2×2 matrix, and the two zeros on the top The first-order resonant units are all connected to the upper port feeder 4, the upper two zero-order resonant units are connected to an isolation resistor 6, and t...

Embodiment 2

[0028] to combine image 3 , the zero-order resonator-based miniaturized high-performance microstrip filter power divider has four identical zero-order resonant units 1, upper port feeder 4, lower port feeder 5, isolation resistor 6, metal floor 7 and dielectric substrate 8, The upper port feeder 4, the lower port feeder 5, the isolation resistor 6 and the four zero-order resonant units 1 are all printed on the upper surface of the dielectric substrate 8, and a metal floor 7 is arranged below the dielectric substrate 8, and the lower port feeder 5 The number is two, and the two lower port feeders are located on both sides of the lower part of the microstrip filter power divider and are symmetrical about the central axis. The four zero-order resonant units 1 are distributed in a 2×2 matrix, and the two zeros on the top The first-order resonant units are all connected to the upper port feeder 4, the upper two zero-order resonant units are connected to an isolation resistor 6, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Gap width | aaaaa | aaaaa |

| Center frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com