Method and device for treating exhaust gas of styrene-butadiene rubber drying oven

A technology for styrene-butadiene rubber and a treatment method, which is applied in separation methods, chemical instruments and methods, and air quality improvement, etc., can solve the problems of large fluctuation range, high styrene concentration, and high temperature, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

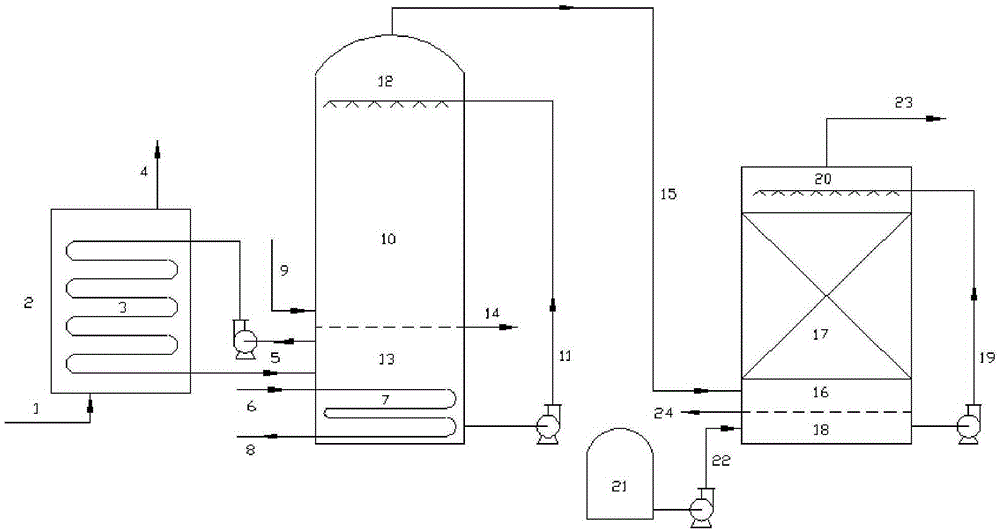

[0034] Styrene-butadiene rubber drying box waste gas 200,000 m 3 / h, temperature 50°C, humidity 95%, non-methane total hydrocarbon content 800mg / m 3 ,according to figure 1 process is processed. The exhaust gas conveying power of the styrene-butadiene rubber drying box comes from the blower, enters from the middle of the spray cooling tower 10 through the air inlet pipe 9, and uses the circulating pump to pressurize and lift the cooling water at 25°C to the top of the tower through the circulating water pipe II 11, and then passes through the spray nozzle Ⅰ 12 Spray downward from the top, the exhaust gas temperature drops to 38°C, and the water storage tank 13 at the bottom of the spray cooling tower 10 has a water storage capacity of 300m 3 , the circulation volume of cooling water is 5000m 3 / h. The exhaust gas volume after cooling is 180,000 m 3 / h, the amount of circulating water increases by 9m after water vapor turns into condensed water 3 / h, this part of excess wa...

Embodiment 2

[0036] Styrene-butadiene rubber drying box waste gas 180,000 m 3 / h, temperature 45°C, humidity 90%, non-methane total hydrocarbon content 400mg / m 3 ,according to figure 1 process is processed. The exhaust gas conveying power of the styrene-butadiene rubber drying box comes from the blower, enters from the middle of the spray cooling tower 10 through the air inlet pipe 9, and uses the circulating pump to pressurize and lift the cooling water at 25°C to the top of the tower through the circulating water pipe II 11, and then passes through the spray nozzle Ⅰ 12 Spray downward from the top, the exhaust gas temperature drops to 36°C, and the water storage tank 13 at the bottom of the spray cooling tower 10 has a water storage capacity of 300m 3 , the circulating volume of cooling water is 4000m 3 / h. The exhaust gas volume after cooling is about 170,000 m 3 / h, the amount of circulating water increases by about 7m after the water vapor turns into condensed water 3 / h, this p...

Embodiment 3

[0038] Styrene-butadiene rubber drying box waste gas 180,000 m 3 / h, temperature 45°C, humidity 90%, non-methane total hydrocarbon content 60mg / m 3 ,according to figure 1 process is processed. The exhaust gas conveying power of the styrene-butadiene rubber drying box comes from the blower, enters from the middle of the spray cooling tower 10 through the air inlet pipe 9, and uses the circulating pump to pressurize and lift the cooling water at 25°C to the top of the tower through the circulating water pipe II 11, and then passes through the spray nozzle Ⅰ 12 Spray downward from the top, the exhaust gas temperature drops to 36°C, and the water storage tank 13 at the bottom of the spray cooling tower 10 has a water storage capacity of 300m 3 , the circulating volume of cooling water is 4000m 3 / h. The exhaust gas volume after cooling is about 170,000 m 3 / h, the amount of circulating water increases by about 7m after the water vapor turns into condensed water 3 / h, this pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com