PVC food packaging composition and preparation method thereof

A technology for food packaging and composition, applied in the application field of polymer materials, can solve the problems of low strength and precipitation of liquid plasticizer, and achieve the effects of high tensile strength, good flow performance and high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

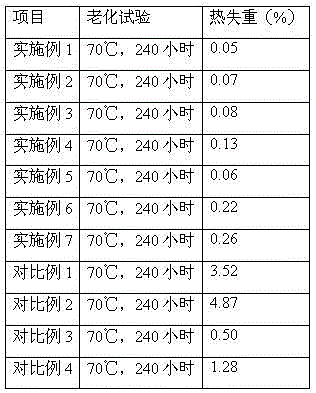

Examples

Embodiment

[0027] The preparation method of embodiment is:

[0028] 1) Mixing of raw materials: first put polyvinyl chloride resin, calcium / zinc stabilizer, phosphite, and lubricant into a high-speed mixer and mix them. When the mixing temperature reaches 100~120°C, transfer the materials to a low-speed mixer When cooling to 35~45°C, add polycaprolactone and compatibility modifier, and continue mixing for 2 to 3 minutes to obtain a compound;

[0029] 2) The compounded material is granulated by a parallel twin-screw extruder or a conical twin-screw extruder. The process parameters of the twin-screw extruder are set as: 1 zone 100°C, 2 zone 120°C, 3 zone 145°C, 140°C in zone 4, 130°C in the machine head.

[0030] The preparation method of the comparative example is as follows: all the materials are mixed in a high-speed mixer at the same time, and the rest of the process is the same as that of the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com