Method for calibrating conic refraction and reflection camera of non-center axial symmetrical system

An axisymmetric, camera-based technology, applied in the field of computer vision, can solve problems such as complex systems and large engineering workloads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

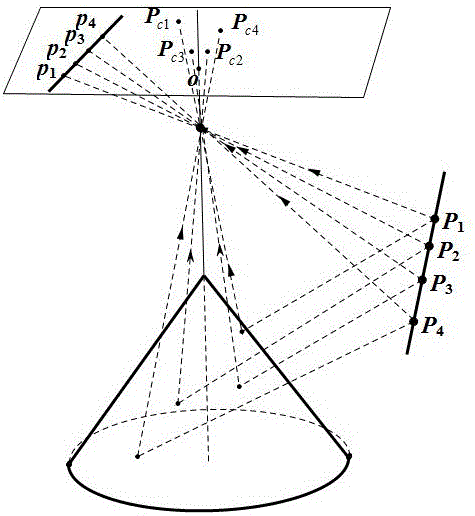

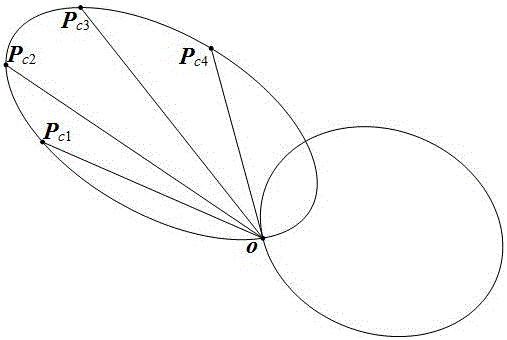

[0060] The invention proposes a method for solving the internal parameters of the conic catadioptric camera by using the cross ratio and polar geometric relationship of the points on the space straight line. The implementation of the present invention will be described in more detail with an example below.

[0061] The calibration of the conic catadioptric camera based on the spatially independent straight line adopts the spatially independent line. Utilize the method among the present invention to carry out calibration to the conical catadioptric camera that is used for experiment, concrete steps are as follows:

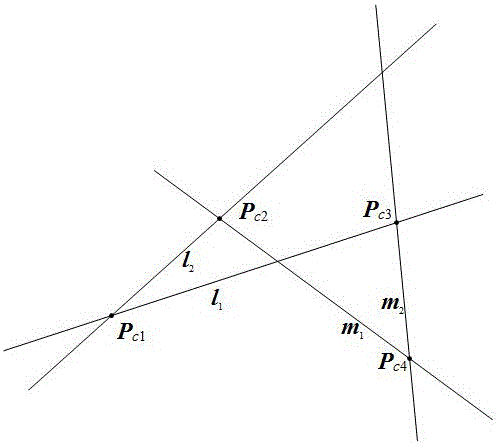

[0062] 1. Determine cross ratio

[0063] in the test straight line take each points, and make each line on The cross-ratio values between the points are equal, and here the cross-ratio is taken as a fixed value , resulting in:

[0064] . (15)

[0065] 2. Cross-ratio invariant research on principal point locus

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com