Quality early warning management method for railway electric service vehicle-mounted equipment

A technology for equipment management and vehicle-mounted equipment, applied in electrical program control, instrumentation, comprehensive factory control, etc., to solve problems such as uncorrected or incorrectly corrected wheel diameter values, time calibration errors, and incorrect color display versions when replacing the monitor version.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

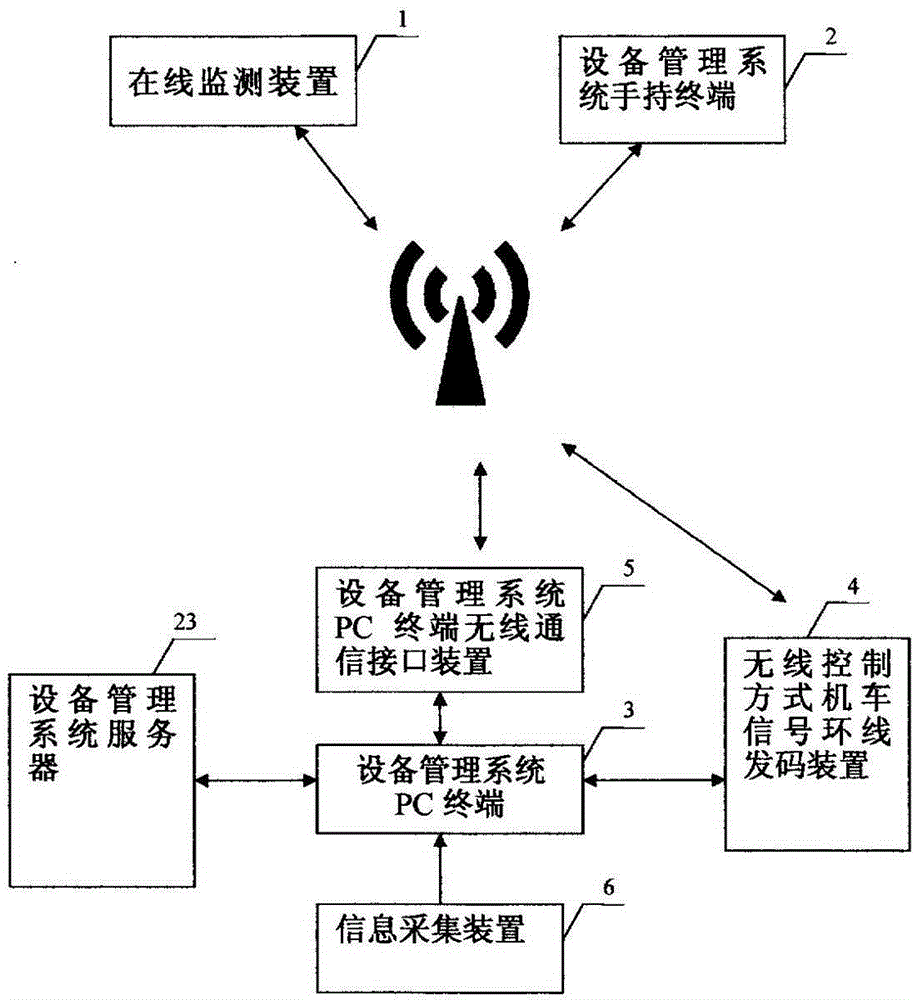

[0026] The premise of the realization of the scheme of the present invention to solve the problem of the railway electric vehicle vehicle equipment quality early warning management method is: figure 1 As shown, the online monitoring device (1), the equipment management system PC terminal (3), the equipment management system handheld terminal (2), and the wireless control mode locomotive signal loop line coding device (4) are connected to each other in a wireless manner. The equipment management system PC terminal (3), equipment management system handheld terminal (2) obtains the data information of the equipment management system server (23) through the network to realize information sharing; the equipment management system PC terminal (3) connects the equipment management system PC terminal through a cable Communication interface device (5), information collection device (6), wireless control mode locomotive signal ring line coding device (4), equipment management system serve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com