Solar cell packaging glue

A technology for solar cells and encapsulant, which is applied in the field of solar cells, can solve the problems of increasing the cost of high-reflection backside encapsulant, pushing up the cost of dyeing encapsulant, and high prices of reflective materials, so as to achieve a significant gain in reflectivity and reduce material costs. , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

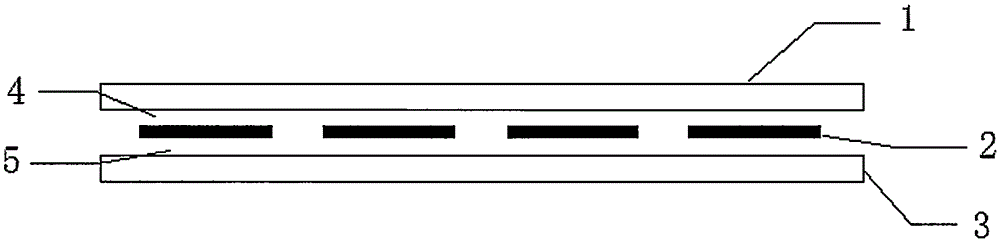

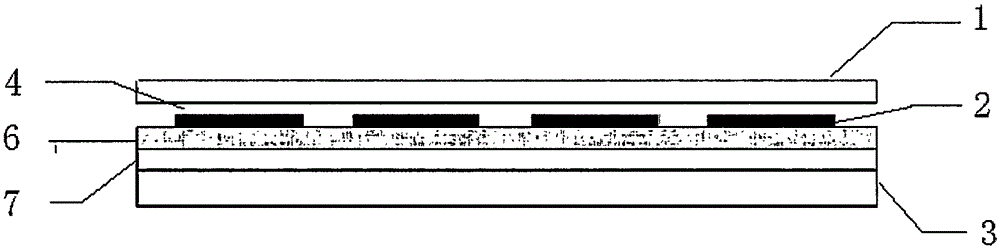

Image

Examples

Embodiment 1

[0022] A kind of solar cell packaging glue The structure is as follows: the layer closer to the cell is a PVB layer containing 10% TiO2, with a thickness of 0.1mm; the middle is a transparent EVA layer, with a thickness of 0.1mm; the layer farther away from the cell is a layer containing 3% TiO2 EVA layer with a thickness of 0.2mm.

[0023] The three film layers are respectively melted and kneaded by different extruders, then extruded, drawn, and then pressed into an integrated structure.

Embodiment 2

[0025] A kind of solar cell packaging glue The structure is as follows: the layer closer to the cell is a white EVA layer containing 12% calcium carbonate, with a thickness of 0.1mm; the layer farther away from the cell is a white EVA layer containing 5% calcium carbonate, with a thickness of 0.1mm 0.3mm.

[0026] The two film layers are respectively melted and kneaded by different extruders, then extruded, drawn, and then compressed into an integrated structure.

Embodiment 3

[0028] A kind of solar cell packaging glue Structure, the layer closer to the cell is a polyolefin layer containing 6% TiO2, with a thickness of 0.1mm; the layer farther away from the cell is a PVB layer containing 8% alumina and 1% barium sulfate, with a thickness of 0.3mm.

[0029] The two film layers are respectively melted and kneaded by different extruders, then extruded, drawn, and then compressed into an integrated structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com