Preparation method of microchip for teaching

A technology of microchip and chip body, which is applied in the field of analytical chemistry teaching equipment, can solve the problems that the teacher's reaction device cannot be self-designed, the price is relatively expensive, etc., and achieve the effects of convenient preparation, cost reduction, and good portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

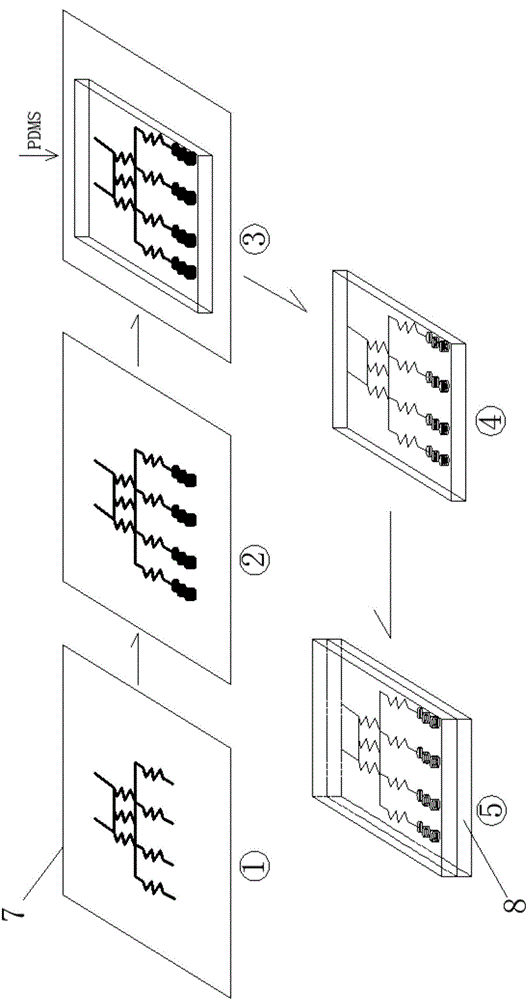

[0036] Refer to attached Figure 1-7 , the present invention provides a kind of preparation method of teaching microchip, adopts hot-melt glue, petri dish, magnetite as template, prepares with polydimethylsiloxane rubber (being PDMS), comprises the following steps:

[0037] 1) Design the position of the pipeline in the petri dish, use hot melt adhesive to draw a raised pipeline model on the corresponding pipeline, and wait for it to solidify;

[0038] 2) Place the petri dish on the surface of the iron box, place a magnetite at the outlet of the pipeline, and complete the template with a three-dimensional space structure;

[0039] 3) Prepare the PDMS glue according to the weight ratio of monomer: curing agent = 1:10, mix and pour into a petri dish, and dry;

[0040] 4) The dried PDMS colloid is peeled off from the petri dish to remove the magnetite;

[0041] 5) Use another PDMS bottom film to seal the surface of the PDMS colloid in step 4 to obtain the chip body.

Embodiment 1

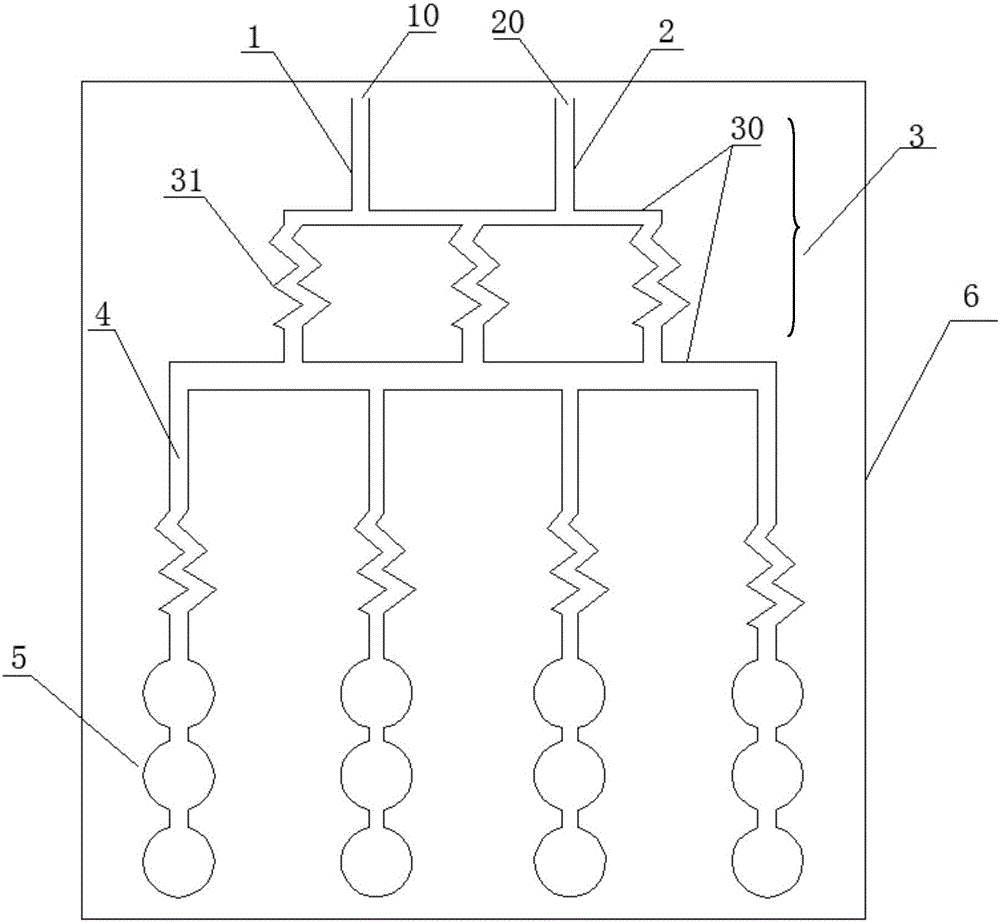

[0043] Such as Figure 1-2 Shown, be a kind of microchip that is used for the teaching of Lambert-Beer's law, it comprises chip body 6, is provided with sampling pipeline 1 and water inlet pipeline 2 in chip body 6, and the entrance of sampling pipeline 1 is provided with inlet Sample port 10, the entrance of water inlet pipe 2 is provided with water inlet 20, and potassium permanganate of certain concentration and pure water can inject in sample inlet pipe 1 and water inlet pipe 2 respectively from sample inlet 10 and water inlet 20, Potassium permanganate and pure water are mixed and enter four sample outlet pipes 4 through the intersection pipe 3, and the outlet of any one of the sample outlet pipes is connected with a plurality of liquid storage tanks 5 with different thicknesses successively, and the intersection pipe 3 is composed of two Two horizontal pipes 30 and longitudinal pipes 31 located between the horizontal pipes are connected to each other and formed, the uppe...

Embodiment 2

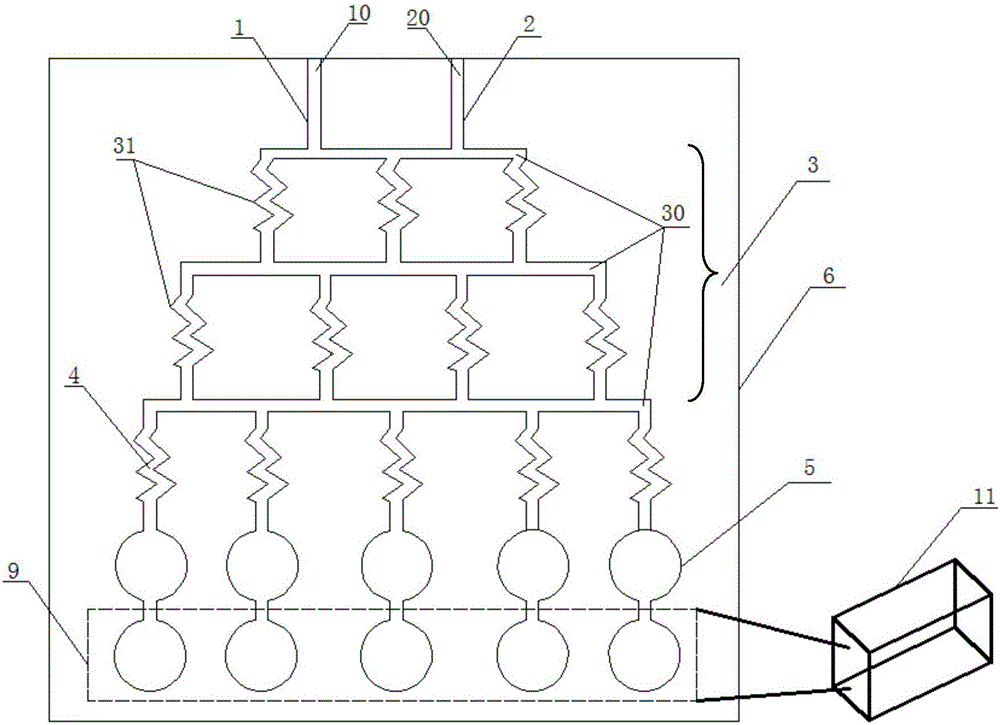

[0052] like Figure 3-4 As shown, it is a microchip used for the teaching of chemical reaction rate, including a chip body 6, which is provided with a sampling pipeline 1 and a water inlet pipeline 2, and the inlet of the sampling pipeline 1 is provided with a sampling port 10. The inlet of the water inlet pipeline 2 is provided with a water inlet 20, and the sample inlet pipeline 1 and the water inlet pipeline 2 are connected to five sample outlet pipelines 4 at the lower end through a converging pipeline, and any one of the sample outlet pipelines 4 The outlets are provided with two connected liquid storage tanks 5, so that the liquid storage tanks are arranged in two rows and five columns at the outlet of the sampling pipeline, and any one of the liquid storage tanks has the same thickness, and the bottom row of liquid storage tanks The tank is integrated with a heating element 9 that can be heated by a battery. The heating element in this design uses a heating sheet. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com