Rod port deburring machine

A technology for deburring machines and rods, which is applied in the direction of machine tools, grinding racks, and grinding workpiece supports suitable for grinding the edge of workpieces. It can solve the problems of unsuitable processing of rods and achieve good processing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

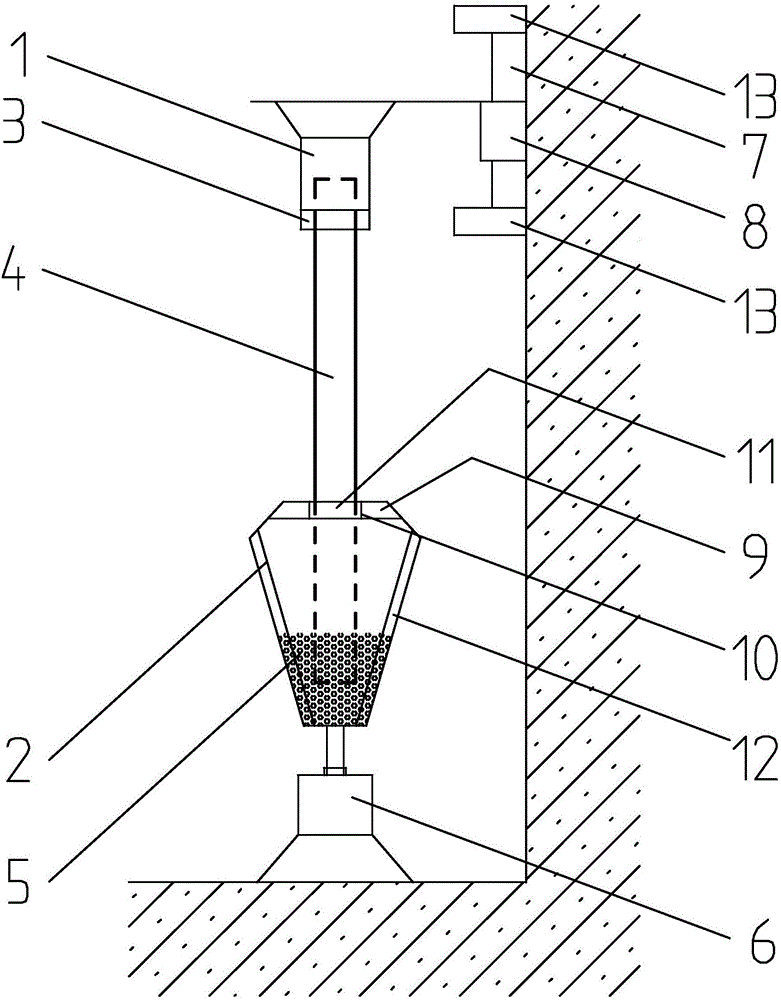

[0018] This embodiment is a rod end deburring machine, which is applied in a copper pipe processing workshop. Such as figure 1 As shown, the rod end deburring machine includes two sets of main structural parts, one is the abrasive pot 2 on the ground and the abrasive pot rotating motor 6, etc., and the other is the clamping rod motor 1 and the linear reciprocating motor fixed on the side wall 8 etc.

[0019] The abrasive pot is a pot body whose diameter is large at the top and small at the bottom, and the bottom is connected with the rotating motor of the abrasive pot, and can rotate around the axis under the drive of the rotating motor of the abrasive pot. The inner wall of the abrasive pot is provided with a plurality of ribs 12 equidistant along the axial direction, and the abrasive pot is provided with granular abrasives 5, the abrasive u...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap