A kind of preparation method of particle assembly spherical sns2 sodium ion battery negative electrode material

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems of small yield of nanosheets, incomplete reaction, poor controllability, etc., and achieve controllable grain growth , The effect of full and thorough reaction and fast reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of particle assembly spherical SnS 2 The preparation method of the negative electrode material of the sodium ion battery includes the following steps:

[0026] 1) SnCl 4 ·5H 2 O is dissolved in deionized water and prepared into solution A with a concentration of 0.6~1.3mol / L, according to the element mass ratio m Sn :m S =(1.85~2.8):(1.0~1.53) Dissolve thioacetamide in the same amount of deionized water (that is, with dissolved SnCl 4 ·5H 2 O with the same amount of deionized water) prepared into solution B;

[0027] 2) Under the action of magnetic stirring, add solution B to solution A drop by drop, continue to stir to obtain uniform mixed solution C, add 0.5mol / L NaOH solution dropwise to adjust the PH value to 4-8 to obtain solution D, then continue to stir 0.5 ~2h;

[0028] 3) Put the mixed solution D in a microwave hydrothermal reactor, control the filling ratio at 15%-30%, put it into a homogeneous hydrothermal reactor, control the reaction temperature at 150-230℃...

Embodiment 1

[0032] 1) SnCl 4 ·5H 2 O is dissolved in deionized water and prepared into solution A with a concentration of 0.6mol / L, according to the element mass ratio m Sn :m S =1.85:1.0 Dissolve thioacetamide in an equal amount of deionized water to prepare solution B;

[0033] 2) Add solution B to solution A dropwise under the action of magnetic stirring, continue stirring to obtain uniform mixed solution C, add 0.5mol / L NaOH solution dropwise to adjust the PH value to 4 to obtain solution D, and then continue stirring for 0.5h;

[0034] 3) Put the mixed solution D in a microwave hydrothermal reactor, control the filling ratio at 15%, put it into a homogeneous hydrothermal reactor, control the reaction temperature at 230°C, and control the reaction time at 8h;

[0035] 4) After the reaction is over, take out the precursor, centrifuge and wash 3 times with deionized water and absolute ethanol, and freeze-dry at -60°C for 10 hours to obtain SnS 2 product.

Embodiment 2

[0037] 1) SnCl 4 ·5H 2 O is dissolved in deionized water and formulated into solution A with a concentration of 0.8mol / L, according to the element mass ratio m Sn :m S =2.0:1.4 Dissolve thioacetamide in an equal amount of deionized water to prepare solution B;

[0038] 2) Under the action of magnetic stirring, add solution B to solution A drop by drop, continue to stir to obtain a uniform mixed solution C, add 0.5mol / L NaOH solution dropwise to adjust the pH to 6 to obtain solution D, and then continue to stir for 1.5h;

[0039] 3) Put the mixed solution D in a microwave hydrothermal reactor, control the filling ratio at 25%, put it into a homogeneous hydrothermal reactor, control the reaction temperature at 190°C, and control the reaction time at 10h;

[0040] 4) After the reaction is over, take out the precursor, centrifuge and wash 4 times with deionized water and absolute ethanol, and freeze-dry at -50°C for 11 hours to obtain SnS 2 product.

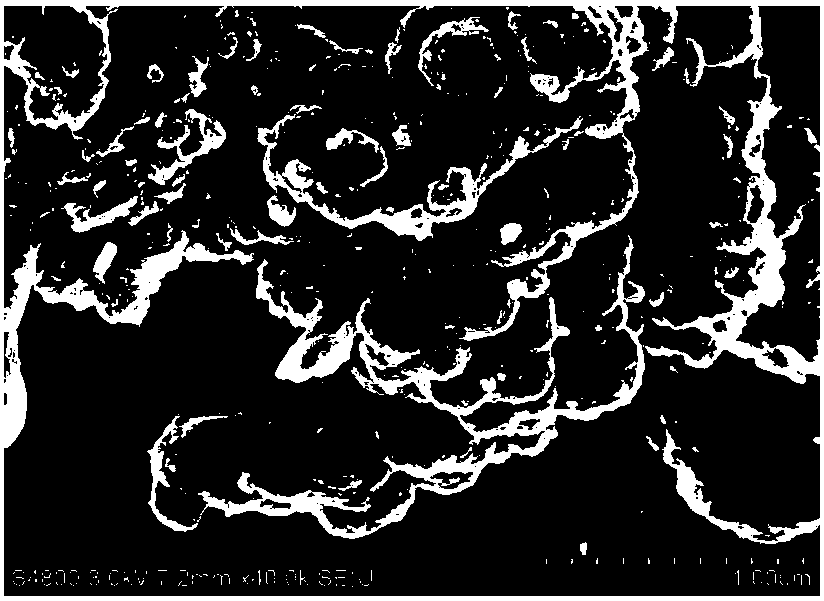

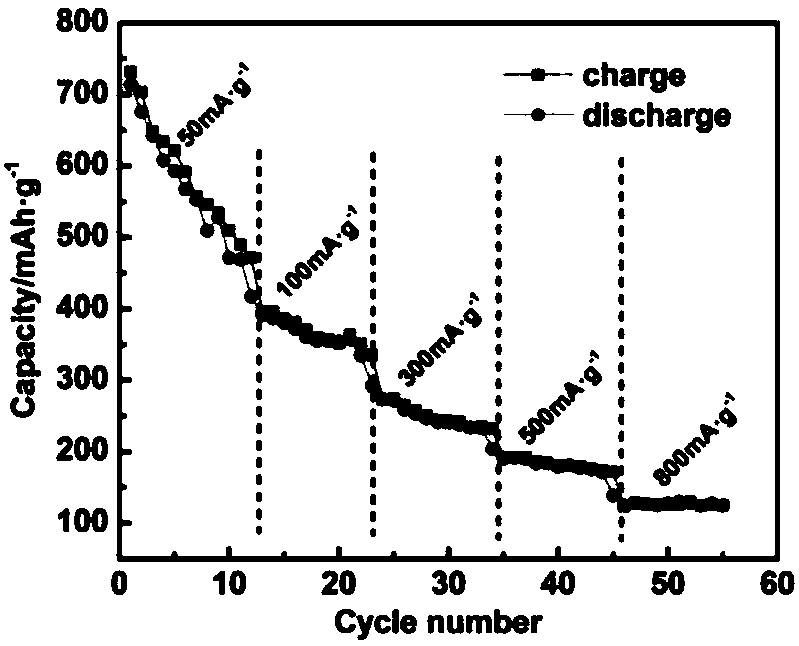

[0041] From figure 1 It can be seen t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com