Methyl hexadecanoate-methyl stearate composite phase-change energy-storage material and preparation method thereof

A technology of methyl stearate and methyl palmitate, which is applied in the field of methyl palmitate-methyl stearate composite phase-change energy storage materials and its preparation, can solve problems such as not meeting the basic requirements of phase-change materials, Achieve the effects of improving comfort, saving energy and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

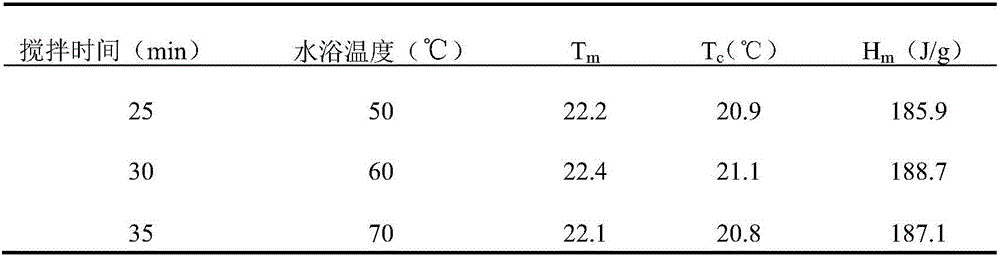

[0016] A method for preparing a methyl palmitate-methyl stearate composite phase-change energy storage material, comprising the following steps: adding methyl palmitate and methyl stearate into a reaction vessel at a mass ratio of 1 / 4 to 4 , heating and stirring in a constant temperature water bath for 25 to 35 minutes and then cooling to room temperature, the temperature of the constant temperature water bath is set at 50°C to 70°C to obtain a methyl palmitate-methyl stearate composite phase change energy storage material.

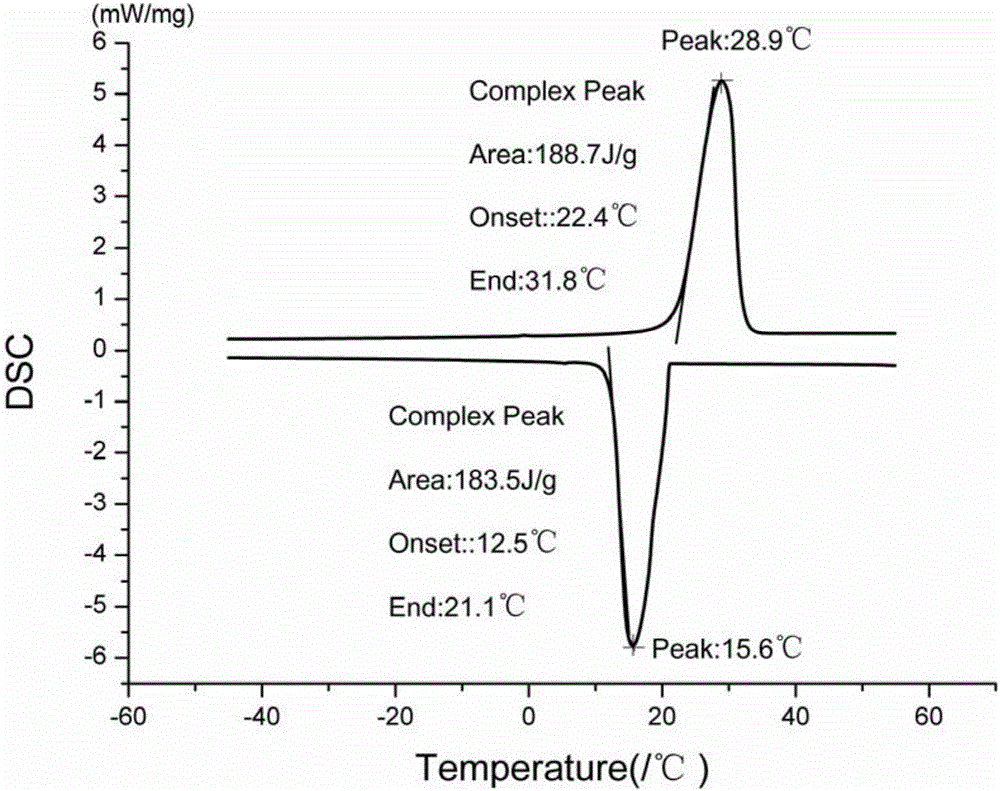

[0017] The mensuration of the phase change temperature and the latent heat of phase change of the present invention adopts differential scanning calorimetry (DSC) to measure the phase change temperature and the latent heat of phase change of the phase change material, and under the control of the program temperature, measure the temperature input to the sample and the standard sample. Thermal power difference versus temperature and time. Each measurement ...

Embodiment 1

[0019] Add methyl palmitate and methyl stearate into a three-necked flask according to the mass ratio of 4:1, place it in a constant temperature water bath, heat and stir for 30 minutes, the speed of the agitator is 100r / min, and the temperature of the constant temperature water tank is 60°C , fully stirred and mixed, and then cooled to room temperature to obtain a methyl palmitate-methyl stearate composite phase change energy storage material. Finally, the energy storage temperature and latent heat of phase change of the methyl palmitate-methyl stearate composite phase change energy storage materials were measured by DSC.

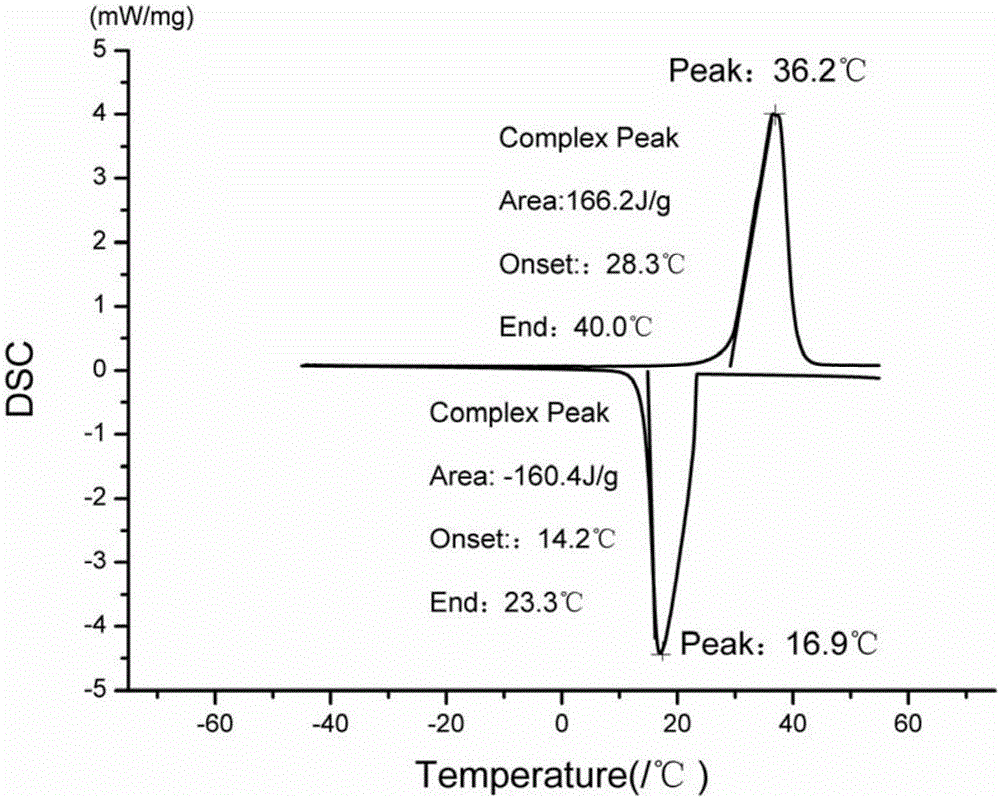

Embodiment 2

[0021] Add methyl palmitate and methyl stearate into a three-necked flask according to the mass ratio of 4:1, heat and stir in a constant temperature water bath for 25 minutes, the speed of the agitator is 100r / min, and the temperature of the constant temperature water tank is 50°C , fully stirred and mixed, and then cooled to room temperature to obtain a methyl palmitate-methyl stearate composite phase change energy storage material. Finally, the energy storage temperature and latent heat of phase change of the methyl palmitate-methyl stearate composite phase change energy storage materials were measured by DSC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com