High surface quality hot rolled steel plate used for manufacturing swing arm of excavator, and manufacturing method thereof

A technology of hot-rolled steel plate and high surface, which is applied in the field of high-surface quality hot-rolled steel plate and its manufacturing, which can solve problems such as unconsidered impact, and achieve the effect of high purity, good weldability, and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

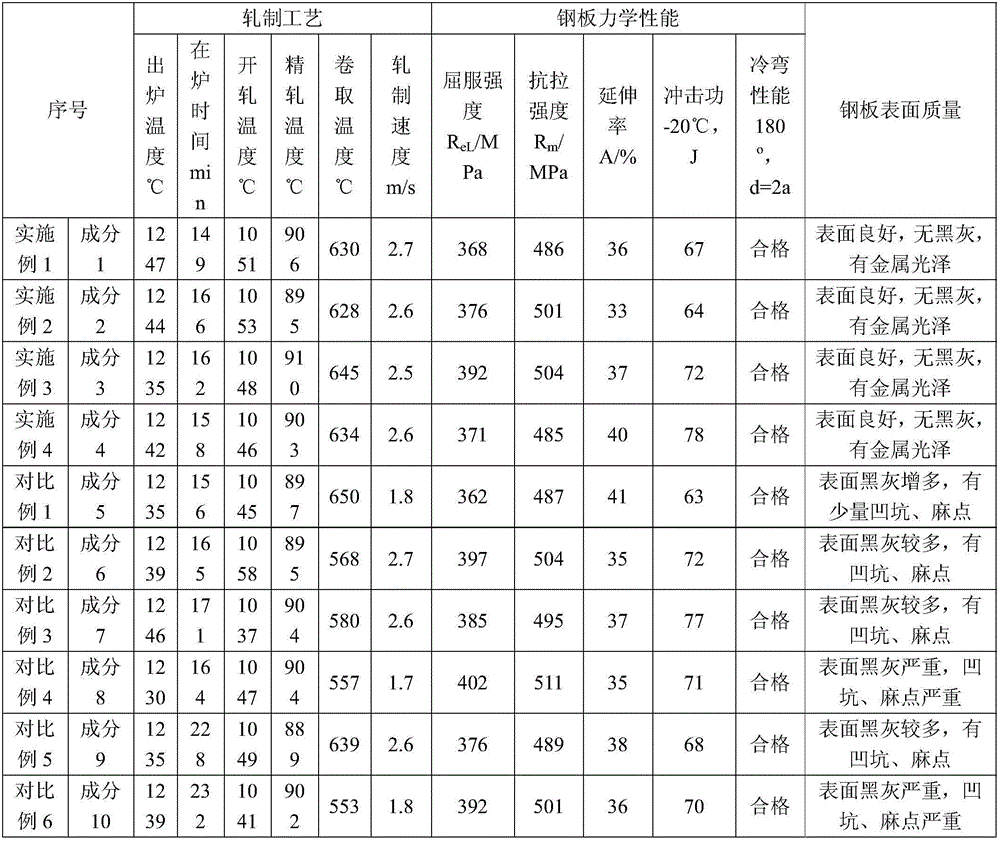

[0043] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

[0044] A hot-rolled steel plate with high surface quality for manufacturing excavator arms and its manufacturing method. During smelting, the weight percentage of Si is controlled between 0.01-0.20 wt%, Nb: 0.005-0.05%, V: 0.01- 0.20%, Ti: 0.01-0.10%. The temperature of the slab out of the furnace is 1200-1300°C, and the time in the furnace is 140-200min to ensure complete solid solution and austenitization of the alloying elements; the starting rolling temperature is 1000-1100°C, the finishing rolling temperature is 850-950°C, and the coiling temperature is 600°C ~700°C; for laminar cooling, using the front-stage rapid cooling method, the cooling rate is 20-50°C / s; when the steel plate width is 900-1500mm, the rolling speed is 3-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com