Efficient power system for ships

A technology for power systems and ships, applied to fuel systems, engine components, combustion engines, etc., can solve the problems of high cost of the whole machine, high quality, safety and technical requirements of storage tanks and auxiliary facilities, etc., and achieve simple overall structure and benefit Effects of environmental protection and job stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

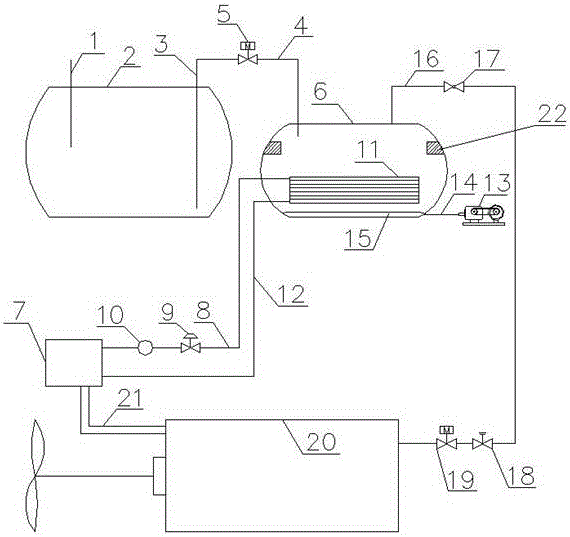

[0025] In order to further explain the present invention, please refer to the accompanying drawings.

[0026] An oil gas ship power system, comprising an oil storage tank 2, a generator 6, a ship engine 20 and an engine waste heat device 7, the oil storage tank 2 is provided with an oil inlet pipe 1 and an oil outlet pipe 3, and the oil outlet pipe 3 The generator 6 is connected to the generator 6 through the oil delivery pipe 4. The generator 6 is provided with a radiator coil 11 in the center, and an air distributor 15 is arranged directly below the radiator coil 11. The radiator coil 11 passes through the waste heat pipe 8 and the return waste heat pipe. 12 is connected with the engine waste heat device 7, the engine waste heat device 7 is connected with the ship engine 20 through the circulating water pipe 21, the gas outlet pipe 16 is provided on the generator 6, and the gas outlet pipe 16 is connected with the ship engine 20 .

[0027] Further, the oil delivery pipe 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com