A One-Dimensional Simulation Method for Predicting Clinker Quality in Cement Rotary Kiln

A technology of cement rotary kiln and simulation method, which is applied in the field of one-dimensional simulation, which can solve the problems of many influencing factors, simulation calculation, matching, etc., and achieve the effect of solving the large deviation from the actual situation and improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

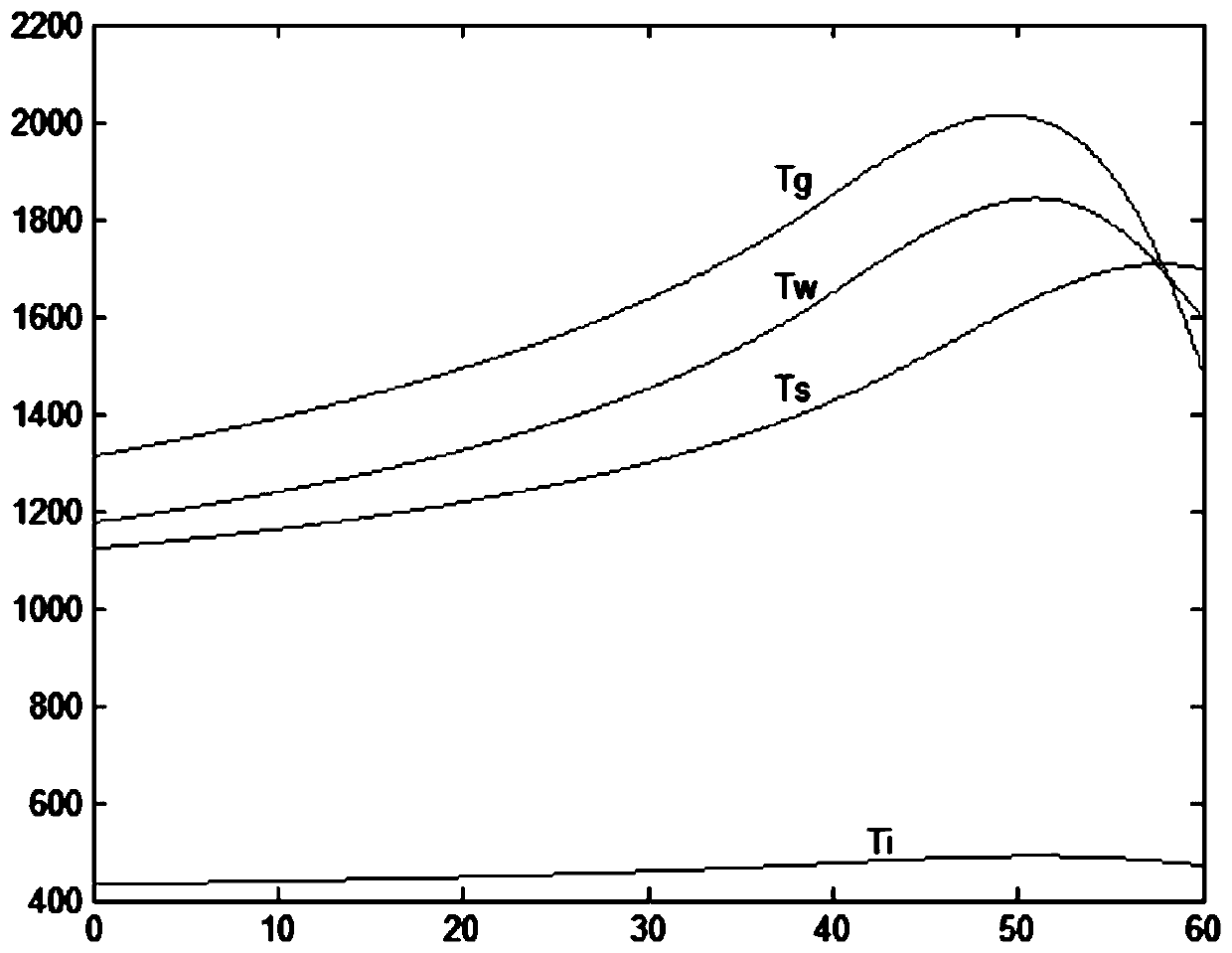

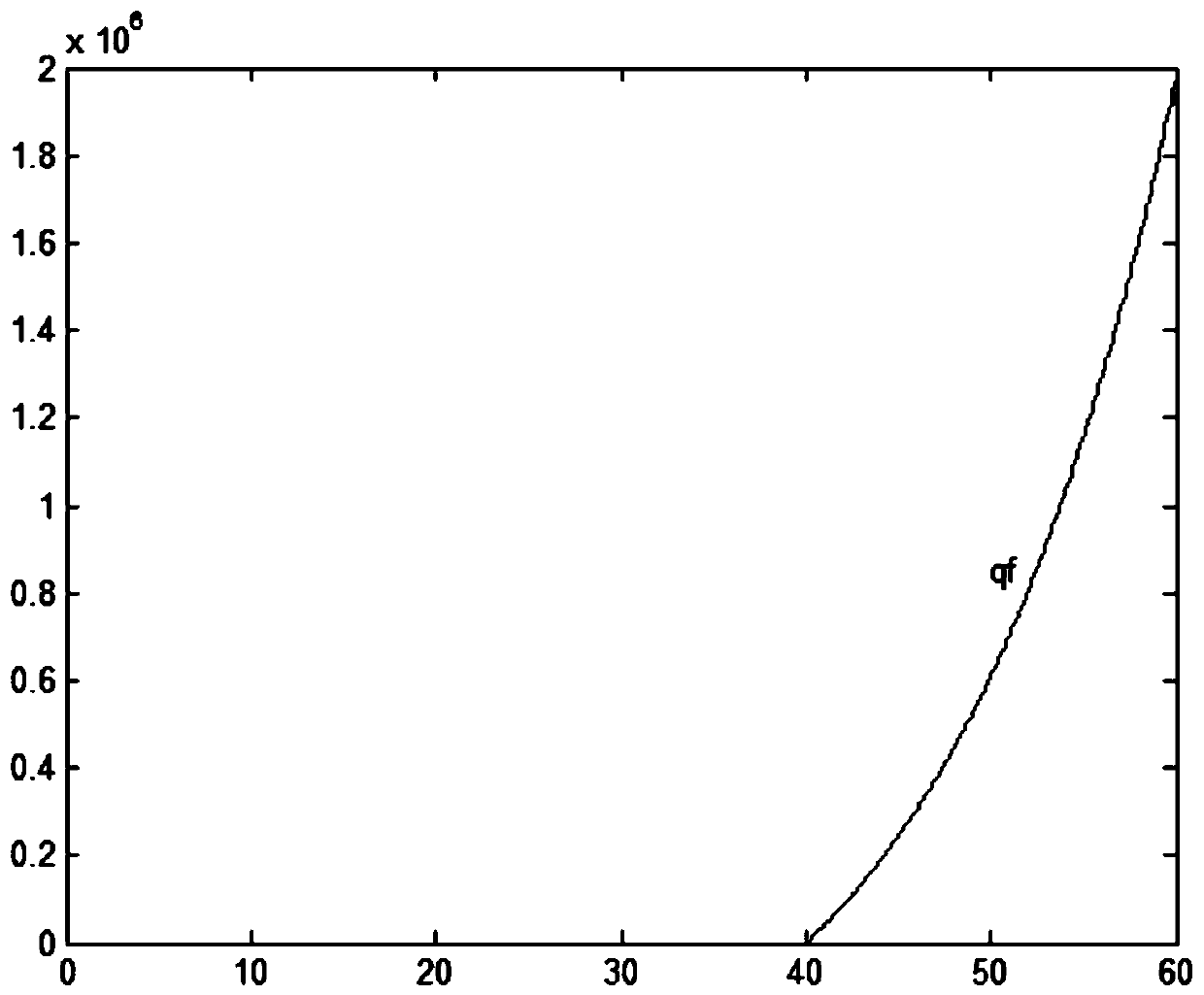

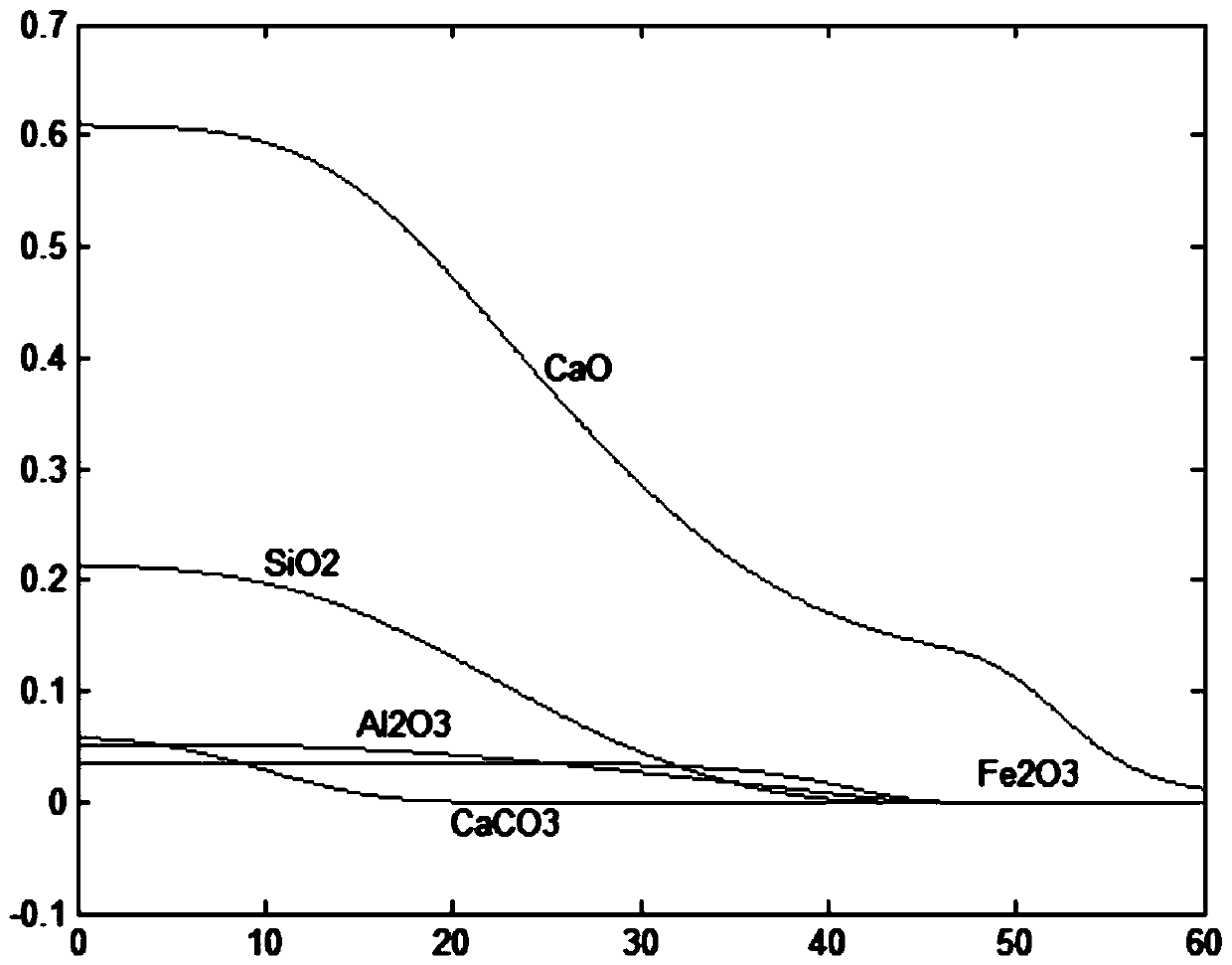

[0107] Table 1 shows the main equipment, process parameters and boundary conditions of a 2500t / d cement clinker production line in China. Based on the parameters shown in Table 1 and the calculation steps of the simulation method described in the present invention, apply the mathematical model described in the present invention to calculate the schematic diagram of the one-dimensional temperature field distribution of the rotary kiln of the production line, the schematic diagram of the change of the heat release of coal pulverized combustion, and the clinker of the rotary kiln. Schematic diagram of chemical composition change and rotary kiln clinker mineral composition change diagram, respectively as Figure 1 to Figure 4 shown. The results are compared with the actual test results to verify the accuracy of the method described in the present invention.

[0108] Table 1 Basic parameters and boundary conditions of the embodiment.

[0109]

[0110]

[0111] figure 1 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com