Method for producing expanded graphite carbon nanotube composite material and supercapacitor produced from expanded graphite carbon nanotube composite material

A technology of expanded graphite and carbon nanotubes, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of limited market application prospects, unsuitable industrial production, unstable preparation process, etc., and achieve easy large-scale production. And the effect of market application, low production cost, excellent electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

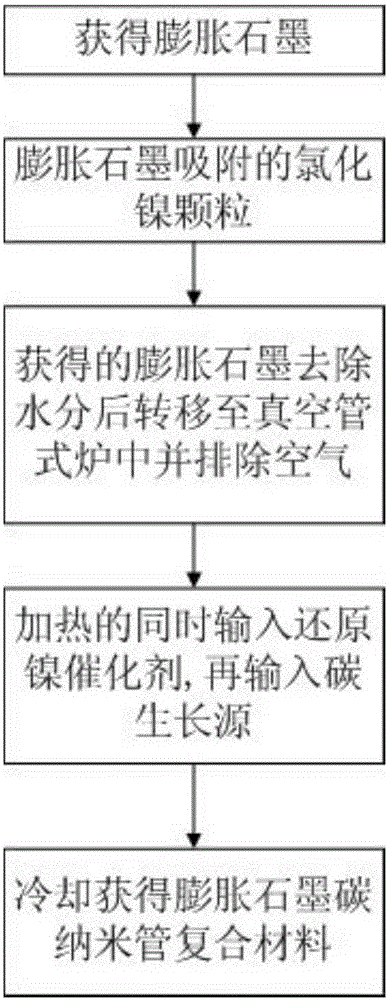

[0029] Such as figure 1 As shown, the invention provides a kind of manufacture method of expanded graphite carbon nanotube composite material, comprises the following steps:

[0030] 1) Expandable graphite is heated under an inert gas environment to obtain expanded graphite. In this embodiment, argon is used as the inert gas (other inert gases are also applicable), and the argon environment is 6×10 -3 m 3 / s-9×10 -3 m 3 / s, heating to 850°C-950°C for more than 20 minutes.

[0031] Preferably, the argon environment is 6×10 -3 m 3 / s, 8.33×10 -3 m 3 / s or 9×10 -3 m 3 / , heating to 850°C, 900°C or 950°C for 20 minutes or more.

[0032] 2) Soak the expanded graphite obtained in step 1) in the nickel chloride particles adsorbed by the nickel chloride solution, the concentration of the nickel chloride solution is 0.01mg / mL-0.03mg / mL, and the duration is greater than or equal to 2 hours.

[0033] Preferably, the concentration of the nickel chloride solution is 0.01 mg / mL, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com