Methods and systems for producing direct reduced iron and steel mill fuel gas

A technology for steel mills and gas, applied in chemical instruments and methods, hydrogen production, combustible gas purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

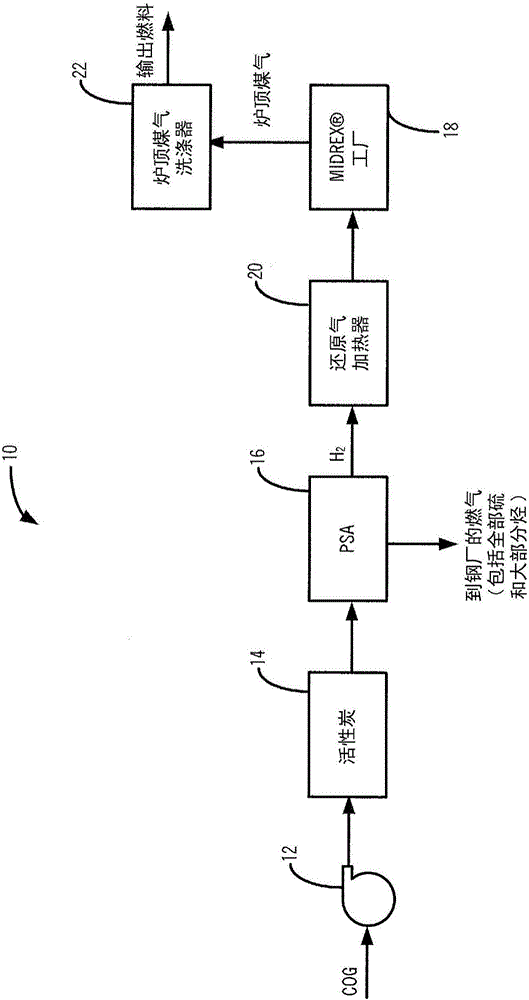

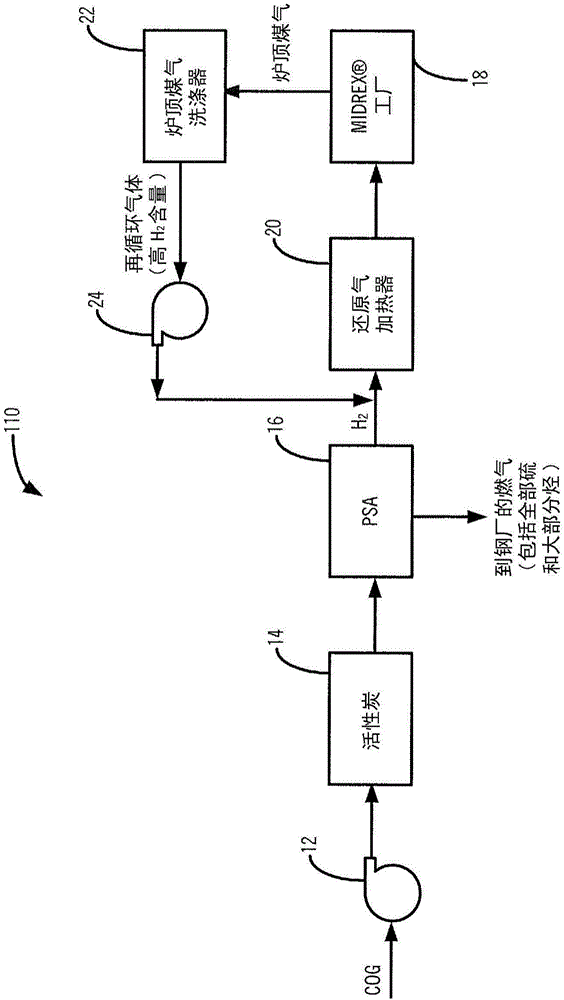

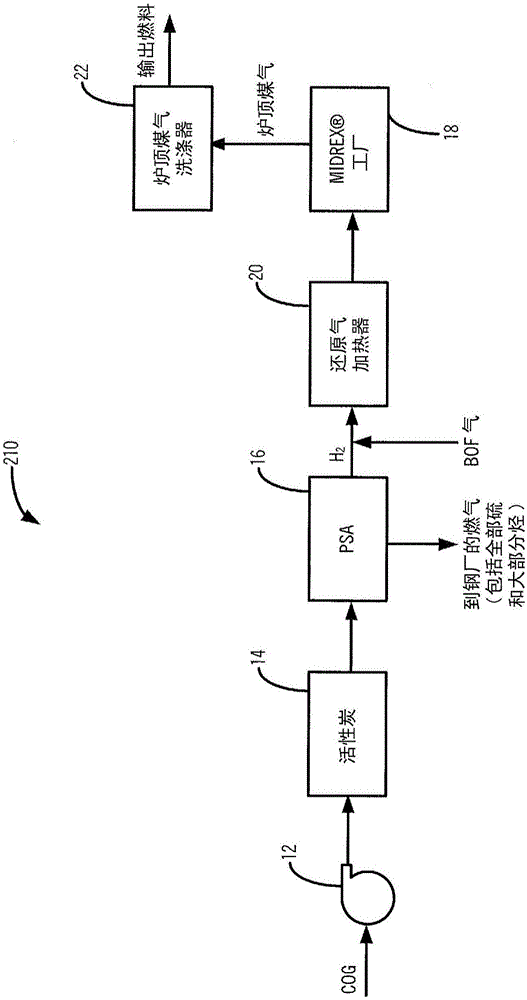

[0017] Likewise, in various exemplary embodiments, the present invention provides the use of COG both as a reducing gas for the production of DRI and as a steel mill gas. The COG is first compressed and then passed through a bed of activated carbon to remove the tar. The COG is then passed through a pressure swing absorption (PSA) unit or the like to produce a high purity H2 stream (about 99% purity) used as reducing gas in the direct reduction shaft furnace. The high purity H2 stream accounts for about 75% of the H2 in COG and about 40% of the total COG stream. The remainder of the COG (including all sulfur and almost all hydrocarbons), about 60% of the total COG, is directed to the steel mill as fuel gas. As a result of using high-purity H2 as the reducing gas, the endothermic (heat-consuming) hydrocarbon cracking and reforming reactions in the direct reduction shaft furnace are avoided, there is no DRI sulfur problem, and there is no concern for removal from the recycle ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com