Modified ZSM-5 molecular sieve, preparation method, and synthetic method for catalytically preparing 3-methyl-3-butene-1-alcohol

A technology of ZSM-5 and molecular sieve, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of increased separation difficulty and energy consumption, low safety factor in the production process, and high energy consumption for separation, so as to achieve production capacity Larger, reduced operation and energy consumption, and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

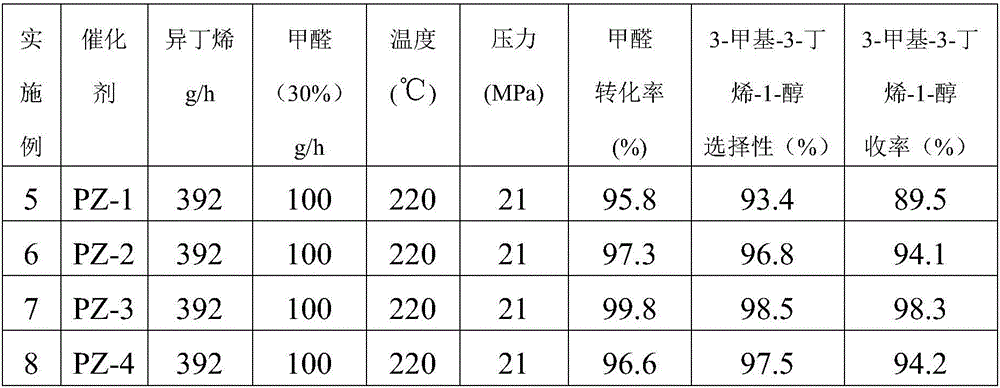

[0030] Place 80g of ZSM-5 molecular sieve (Tianjin Nanhua Catalyst Co., Ltd., model NKF-5) in a fixed-bed reactor, control the reaction temperature to be 600°C, and feed deionized water with a flow rate of 80g / h with a metering pump for 5 hours Afterwards, the deionized water was stopped, and the system was purged with nitrogen for 2 hours in order to drive away the water in the system, and the temperature was lowered to room temperature to obtain a steam-treated ZSM-5 molecular sieve catalyst, which was designated as PZ-1.

Embodiment 2

[0032] The PZ-1 catalyst that 50g is obtained by embodiment 1 is joined in the lanthanum nitrate solution of 80g0.4wt% and stand for 8 hours, filter, dry, and roast 6 hours under 550 ℃ in muffle furnace, obtain improved The permanent ZSM-5 catalyst is denoted as PZ-2.

Embodiment 3

[0034] The PZ-1 catalyst that 50g is obtained by embodiment 1 was joined in the lanthanum nitrate solution of 80g1.0wt% and stood for 8 hours, filtered, dried, and roasted for 6 hours under 550 ℃ in the muffle furnace, obtained improved The permanent ZSM-5 catalyst is denoted as PZ-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com