Leaching method for remediating hexavalent chromium contaminated soil

A technology of polluting soil and hexavalent chromium, applied in the field of environmental engineering, can solve the problems of secondary water pollution and large water consumption, and achieve the effect of low cost, easy operation and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

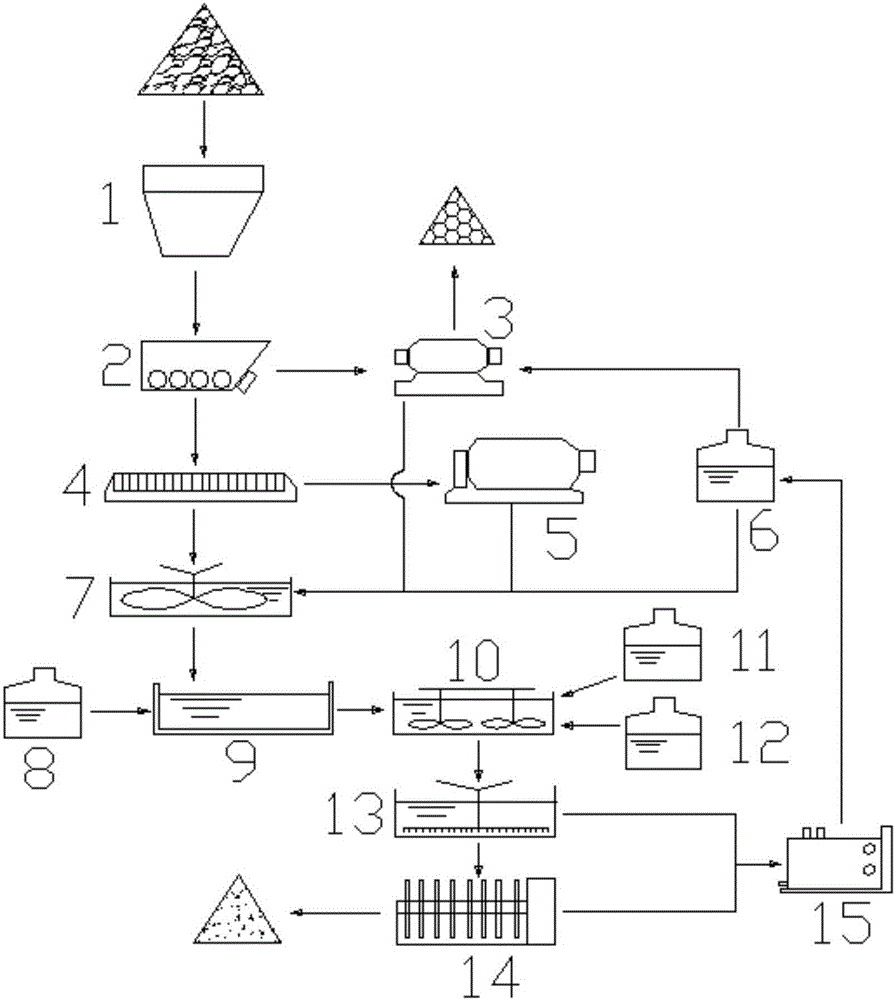

Image

Examples

Embodiment 1

[0038] Taking a chromium salt factory in Gansu as an example, the chromium-contaminated soil is subjected to ex-situ leaching treatment. The specific process and restoration effects are as follows:

[0039] According to field testing, the soil pH is about 7.2 to 8.8, and the hexavalent chromium pollution concentration range is 534.70 to 17883.2 mg / kg. For this kind of chromium-containing slag polluted soil with high content of acid-soluble hexavalent chromium, only providing reducing agent and neutralizer can not completely detoxify the soil. Wet grinding must be performed to destroy the physical structure of the slag particles to make the acid soluble state. , The oxidizable state, the reducible state and the residue state are leached by the agent to more fully react with the reducing agent.

[0040] Transport the contaminated soil to the ex-situ treatment area, fill the contaminated soil to the receiving hopper (1), drop from the discharge port to the rod-type vibrating feeder (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com