Test system of high-lift control system

A control system and test system technology, applied in the direction of aircraft component testing, etc., can solve the problems of lack of versatility, complex operation process, difficult implementation, etc., to achieve the effect of complete function, improve test efficiency, and shorten test cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

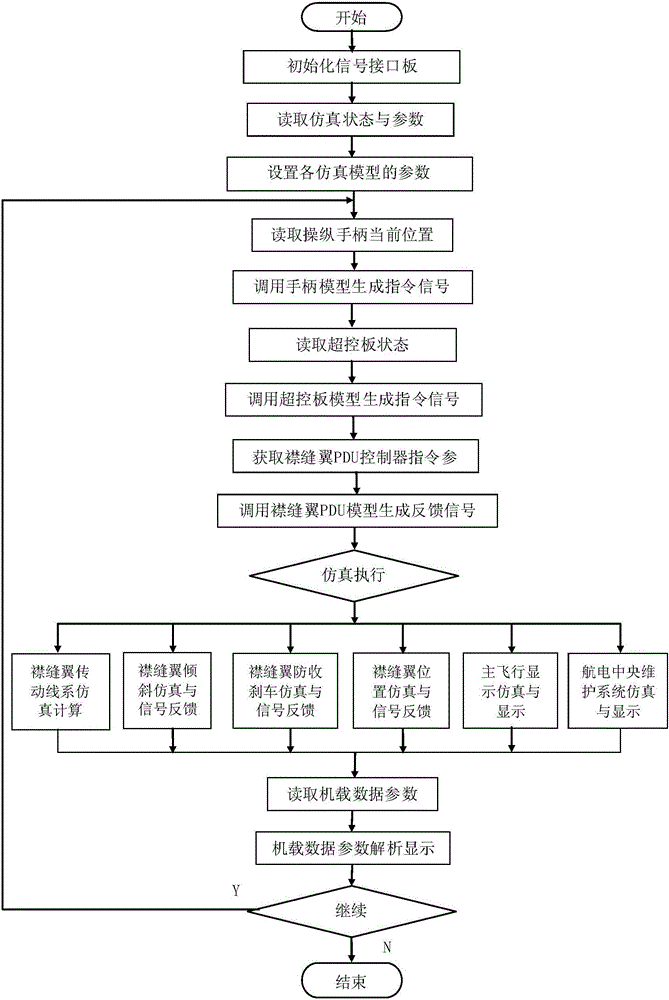

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

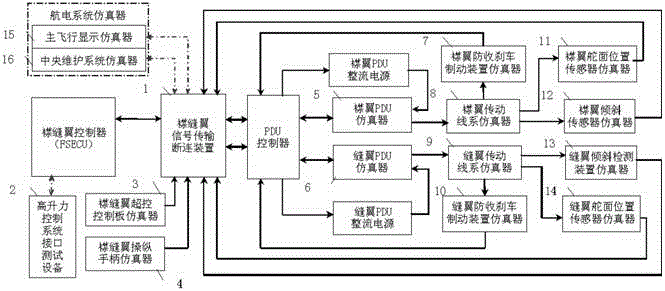

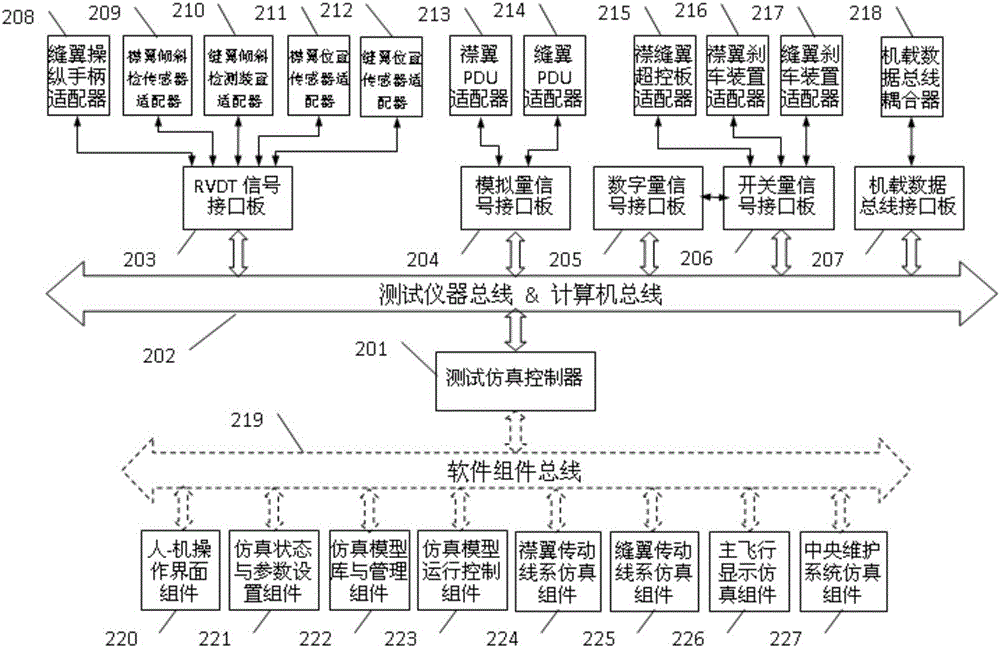

[0046] A test system and method for a high-lift control system, including a high-lift signal transmission disconnection device [1] for completing high-lift control computer-related cross-linking signal detection, high-lift control system interface test equipment [2], and Flap and slat override control board simulator[3], flap and slat joystick simulator[4], flap PDU (power drive unit) simulator[5], slat PDU (power drive unit) simulator[6] ], flap anti-retraction braking device simulator[7], flap transmission line simulator[8], slat transmission line simulator[9], slat anti-retraction braking device simulator[10] ], flap rudder position sensor simulator[11], flap tilt sensor simulator[12], slat tilt detection device simulator[13], slat rudder position sensor simulator[14], avionics system The main flight display simulator [15] and the central maintena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com