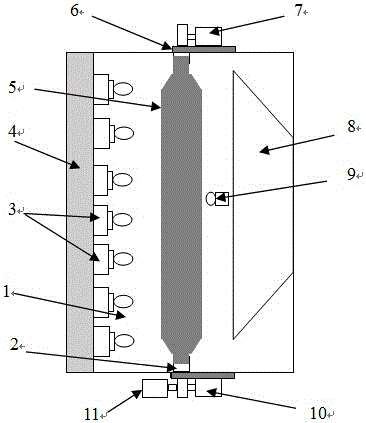

Equipment for depositing optical fiber preforms by OVD (Outside Vapor Deposition) process

An optical fiber preform and process technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve problems such as process control instability and flame state changes, and achieve the effects of improved deposition accuracy and quality, less dispersion, and improved deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0016] Including a closed deposition chamber 1, a row of equally spaced torches 3 are vertically arranged on one side of the deposition chamber, and the torches are arranged on the torch frame and connected with the air inlet guide chamber 4. The up and down reciprocating mobile platform and the driving device 11 are installed on the outer sides of the upper and lower sides of the middle part of the deposition chamber. To make the deposition more uniform, the upper and lower rotary chucks 2 are installed on the horizontal moving seat, and the upper and lower rotary chucks are connected with the synchronous rotation drive mechanism 7 so that they rotate up and down synchronously. A range finder 9 is installed corresponding to the powder stick in the deposition chamber, the output end of the range finder is connected with the PLC control unit, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com