Two-step process silane crosslinking low-smoke halogen-free flame-retarding polyolefin cable material and manufacturing method of same

The technology of polyolefin cable material and silane method is applied in the field of wire and cable, which can solve the problems of uncontinuous preparation process of wire and cable, prone to pre-crosslinking reaction, decreased resin fluidity, etc., and achieves the problems of improving processability and smooth surface of wire. , easy to control, smooth extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

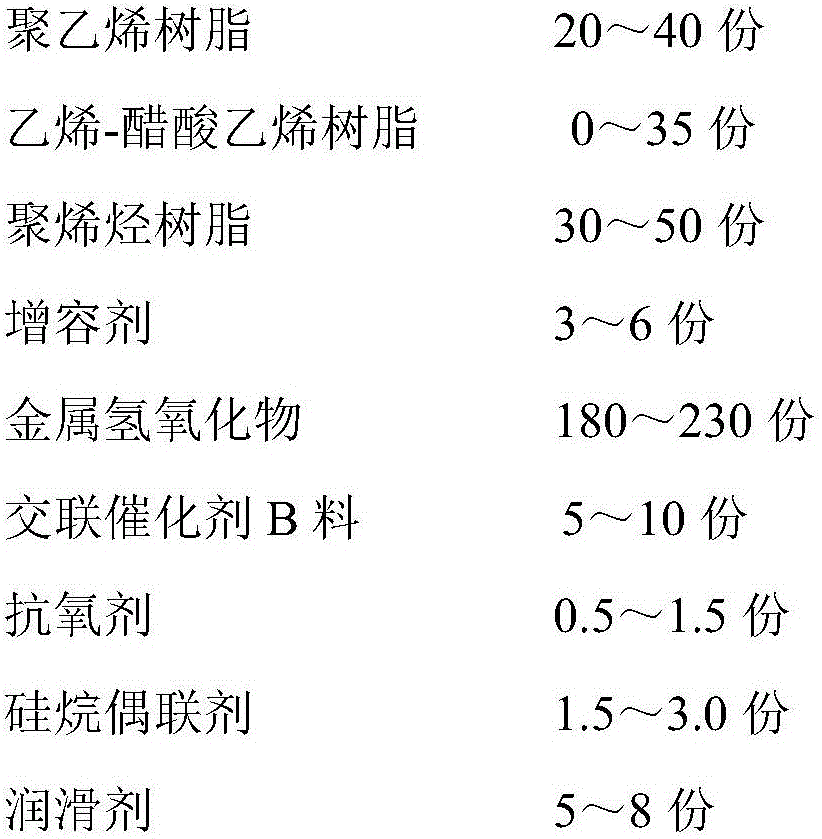

[0039] formula:

[0040] The mass ratio of silane-grafted polyethylene material A to low-smoke, halogen-free, flame-retardant polyolefin flame-retardant masterbatch containing cross-linking catalyst material B is: 15:85;

[0041] The formula and preparation method of A material:

[0042] formula:

[0043] The silane-grafted polyethylene A material includes the following components in parts by weight:

[0044] 100 parts of polyethylene resin, 1.6 parts of compounded silane, 1.0 parts of antioxidant.

[0045] The polyethylene resin is linear low density polyethylene, and its melt index is 2g / min.

[0046] Described complex silane is made up of the component of following mass fraction:

[0047] 100 parts of silane coupling agent, 2.7 parts of initiator;

[0048] Described silane coupling agent is vinyltrimethoxysilane;

[0049] Described initiator is dicumyl peroxide;

[0050] The antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol es...

Embodiment 2

[0079] The mass ratio of silane-grafted polyethylene material A to low-smoke, halogen-free flame-retardant polyolefin flame-retardant masterbatch containing cross-linking catalyst material B is: 12:88;

[0080] The formula of material A:

[0081] Formula: parts by weight

[0082] 100 parts of polyethylene resin, 2.0 parts of compound silane, 2.0 parts of antioxidant;

[0083] Other and preparation method are with embodiment 1;

[0084] Crosslinking catalyst B material formula: parts by weight:

[0085] 100 parts of polyethylene resin, 3.0 parts of catalyst; 3.0 parts of antioxidant; 2.0 parts of anti-copper agent;

[0086] Other and preparation method are with embodiment 1;

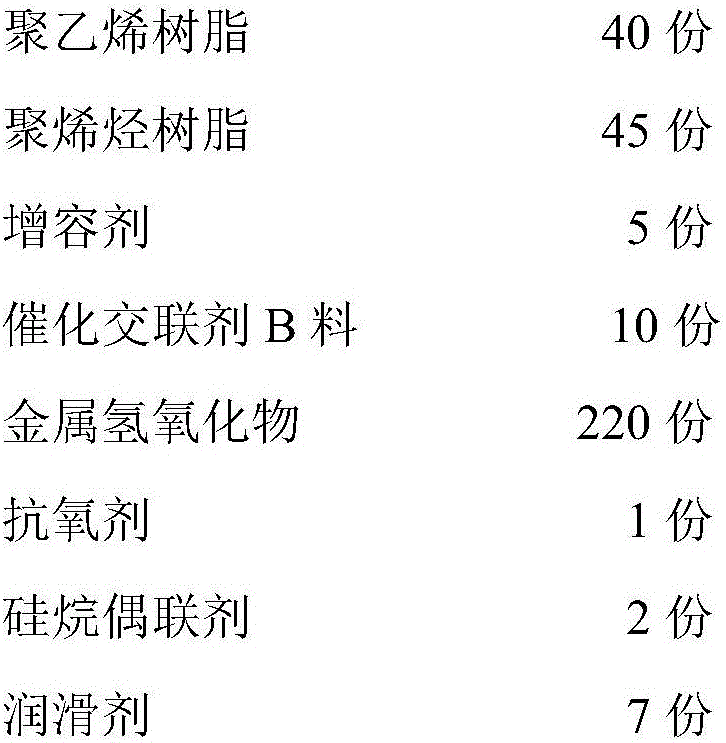

[0087] The low-smoke, halogen-free, flame-retardant polyolefin flame-retardant masterbatch containing the crosslinking catalyst material B includes the following components in parts by weight:

[0088]

[0089]

[0090] Described polyethylene resin is a high fluidity linear low density polyethy...

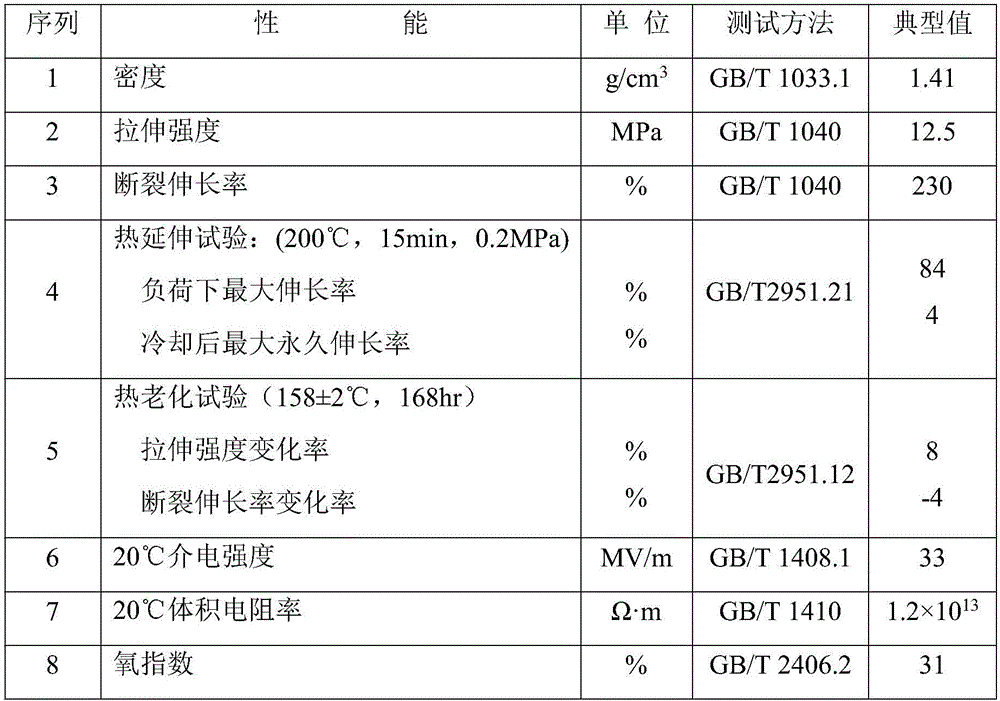

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com