Fluorine-containing organosilicon glass resin, preparation method of resin, transparent heat-insulating glass coating and preparation method of coating

A glass resin and heat-insulating glass technology, applied in reflective/signal coatings, antifouling/underwater coatings, coatings, etc., can solve the problem of insufficient heat insulation performance, low shading coefficient, hardness and water resistance of transparent heat-insulating glass coatings , transparency, weather resistance, adhesion, anti-fouling and other problems such as poor performance, to solve the problem of unsatisfactory thermal insulation performance, low surface tension, and good leveling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

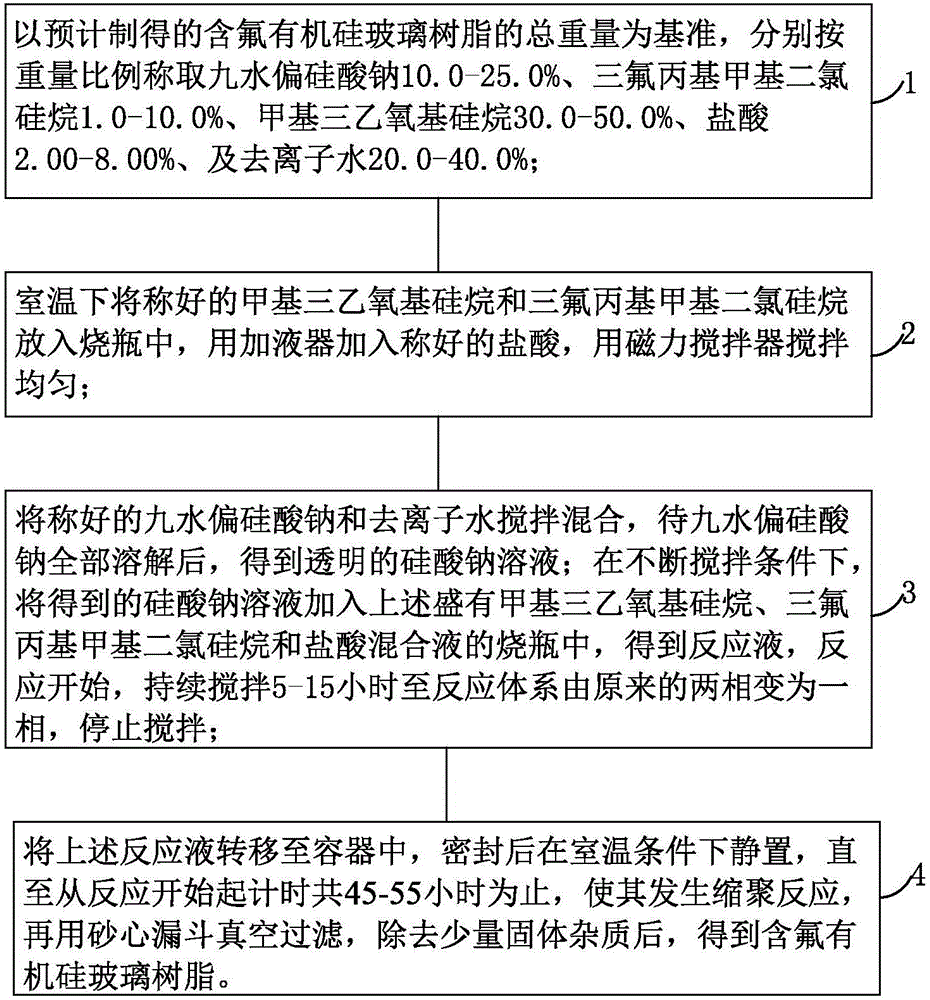

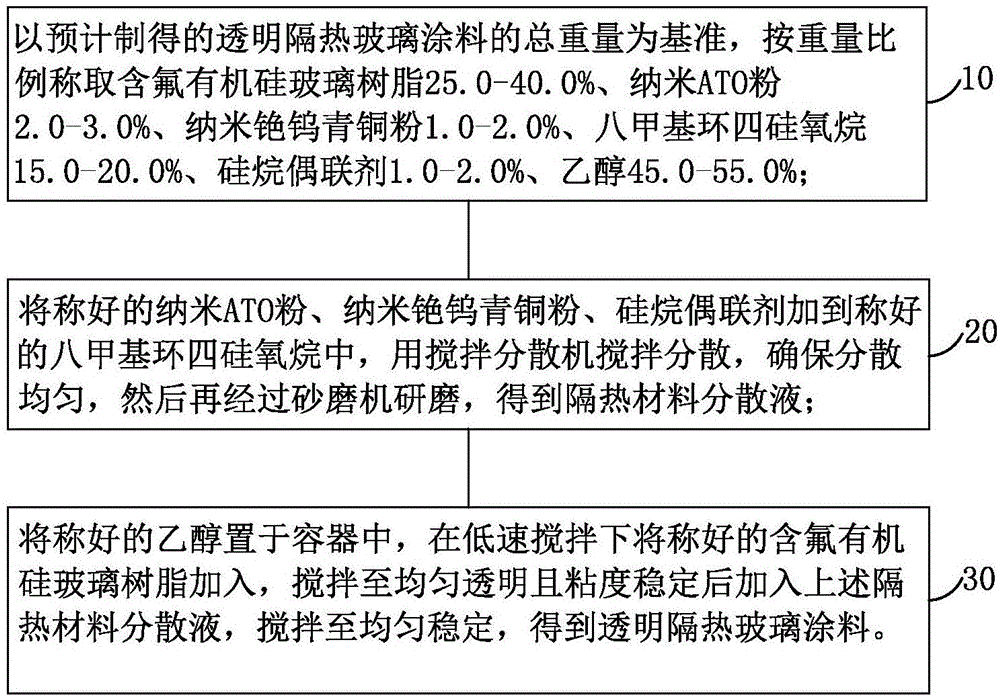

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

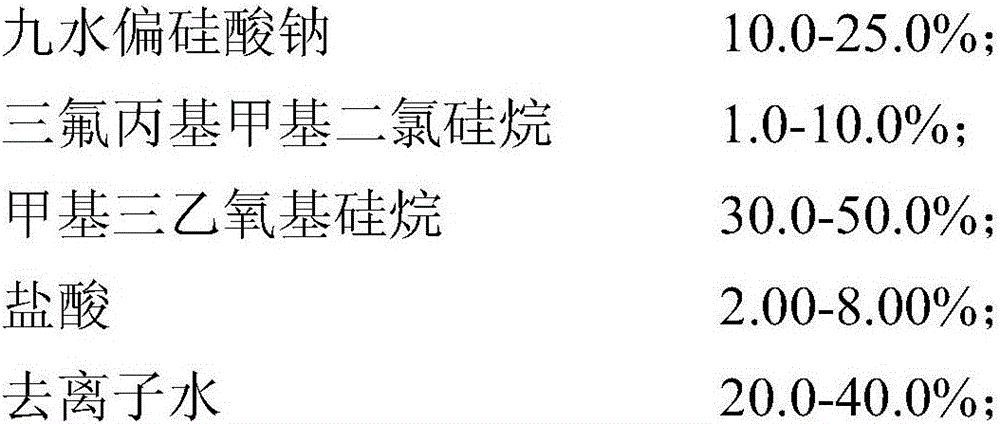

[0033] The present invention firstly provides a kind of fluorine-containing silicone glass resin, the components and weight percentages of which are included in the preparation formula are as follows:

[0034]

[0035] Wherein, the hydrochloric acid is commercially available concentrated hydrochloric acid, and its mass percent concentration is 36-38%.

[0036] The fluorine-containing organic silicon glass resin of the present invention can form a highly transparent and high-hardness organic silicate glass layer after the resin is cured, and can form a mosaic interaction with inorganic silicate glass because of its molecular structure similar to that of inorganic silicate glass. Even structure, so it can greatly increase the adhesion of heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com