Palm oil based pipe free agent and preparation method thereof

An oil-based anti-jamming agent, palm technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., to achieve the effects of reducing time required, improving drilling efficiency, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

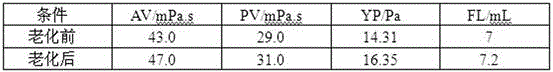

Examples

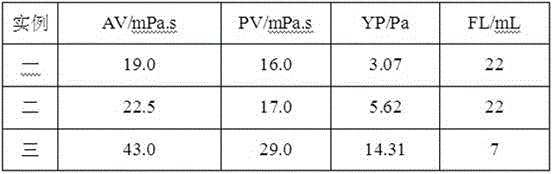

Embodiment 1

[0024] Embodiment 1: a kind of palm oil-based jam-releasing agent mentioned in the present invention and preparation method comprise the following steps:

[0025] Take 320mL of palm oil in a slurry cup, add organic soil JHA6 under stirring at a speed of 3000~4000r / min, and its mass percentage concentration is 5%, and then stir the liquid at a speed of 8000~10000r / min for 5min; then Add emulsifier span80, its mass percentage concentration is 5%, and then stir at a rate of 8000~10000r / min for 5min; then add fast penetrating agent T, its mass percentage concentration is 2%, and then add oleic acid, its mass percentage The concentration is 2%, and then stir at a rate of 8000~10000r / min for 5min; then slowly add 20mL of CaCl under stirring at a rate of 3000~4000r / min 2 (concentration 20%) aqueous solution, and finally stirred at a speed of 8000~10000r / min for 20min.

Embodiment 2

[0026] Embodiment 2: a kind of palm oil-based jam-releasing agent mentioned in the present invention and preparation method comprise the following steps:

[0027] Take 320mL of palm oil in a slurry cup, add organic soil JHA6 under stirring at a speed of 3000~4000r / min, its mass percentage concentration is 4%, and then stir the liquid at a speed of 8000~10000r / min for 5min; Under stirring at a speed of 3000~4000r / min, add fluid loss reducer with a mass percentage concentration of 1%, and then stir the liquid at a speed of 8000~10000r / min for 5 minutes; then add emulsifier dodecylbenzene Sodium sulfonate, its mass percentage concentration is 4% respectively, carry out 5min speed again and be the stirring of 8000~10000r / min; Then add fast penetrating agent T, its mass percentage concentration is 1%, then add oleic acid, its mass percentage concentration 1%, stirring at a rate of 8000~10000r / min for 5min; then slowly adding 20mL of NaCl (concentration 20%) aqueous solution under s...

Embodiment 3

[0028] Embodiment 3: a kind of palm oil-based jam-releasing agent mentioned in the present invention and preparation method comprise the following steps:

[0029] Take 320mL of palm oil in a slurry cup, add organic soil JHA6 under stirring at a speed of 3000~4000r / min, its mass percentage concentration is 6%, and then stir the liquid at a speed of 8000~10000r / min for 5min; Under stirring at a speed of 3000~4000r / min, add fluid loss reducer with a mass percentage concentration of 4%, and then stir the liquid at a speed of 8000~10000r / min for 5 minutes; then add emulsifier op-10, the The mass percentage concentration is 5% respectively, and then the speed of 5min is stirred at 8000 ~ 10000r / min; then the fast penetrating agent T is added, and its mass percentage concentration is 3%, and then oleic acid is added, and its mass percentage concentration is 3%. Then carry out stirring at a speed of 8000~10000r / min for 5min; slowly add 64mL of CaCl under stirring at a speed of 3000~40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com