Foaming agent composition for high temperature gas drive and preparation method thereof

The technology of a composition and a foaming agent is applied in the field of foaming agent composition and preparation for gas flooding of high temperature oil reservoirs, which can solve the problems of high viscosity fingering and high resistance factor, and achieve the enhancement of stability, reduction of interfacial tension and increase of adsorption capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

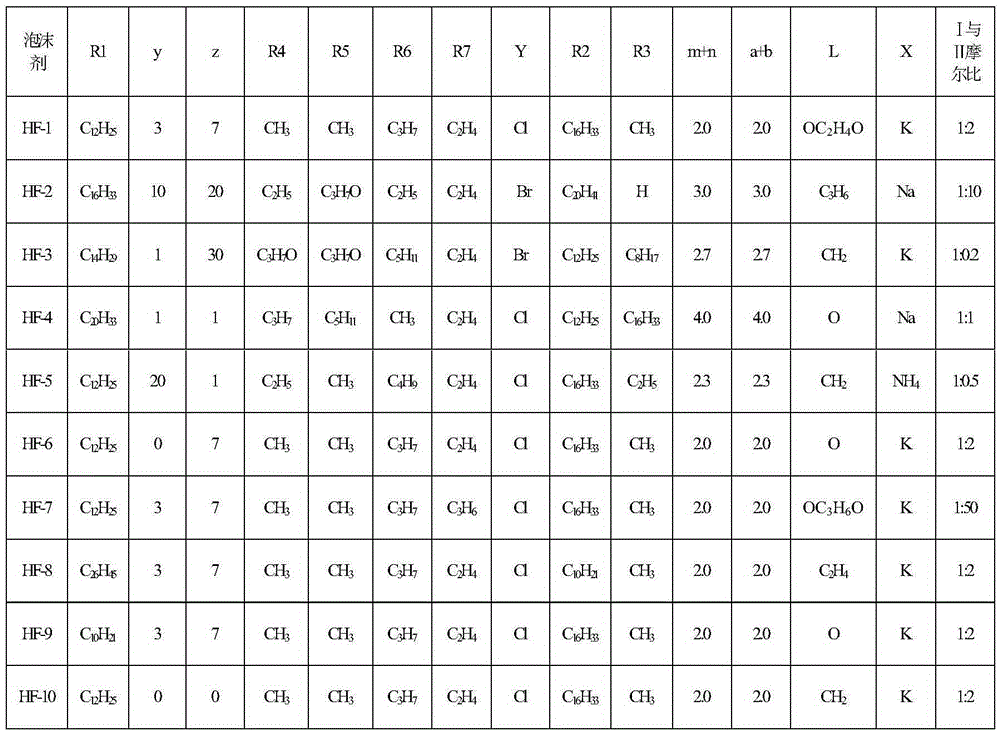

Embodiment 1

[0041] The preparation of composition HF-1, preparation steps:

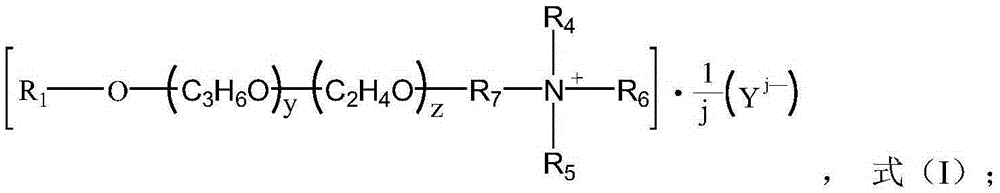

[0042] (1) Long-chain polyether nitrogen-containing compound (C 12 h 25 O(CHCH 3 CH 2 O) 3 (CH 2 CH 2 O) 7 CH 2 CH 2 N(CH 3 ) 2 C 3 h 7 Cl) Synthesis and preparation:

[0043] Add 186.0 grams of dodecanol and 5.6 grams of potassium hydroxide to a pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, dehydrate under high vacuum for 1 hour, and then replace with nitrogen for 3- 4 times, adjust the reaction temperature of the system to 150 ° C and slowly pass 179.9 grams of propylene oxide, control the pressure ≤ 0.60 MPa, lower the temperature to 90 ° C, remove low boilers in vacuum, continue to adjust the reaction temperature of the system to 150 ° C and slowly pass Inject 360.0 grams of ethylene oxide and control the pressure to ≤0.60MPa. After the reaction, neutralize and dehydrate after cooling to obtain C 12 h 25 O(CHCH 3 CH 2 O) 3 (CH 2 CH ...

Embodiment 2

[0050] The preparation of composition HF-2, preparation steps:

[0051] (1) Long-chain polyether nitrogen-containing compound (C 16 h 33 O(CHCH 3 CH 2 O) 10 (CH 2 CH 2 O) 20 CH 2CH 2 N(C 2 h 5 )(C 3 h 7 O)CH 3 Br) synthesis and preparation:

[0052] Add 121 grams of cetyl alcohol and 3 grams of potassium hydroxide to a pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, dehydrate under high vacuum for 1 hour, and then replace with nitrogen for 3- 4 times, adjust the reaction temperature of the system to 150 ° C and slowly pass 300 grams of propylene oxide, control the pressure ≤ 0.60 MPa, cool down to 90 ° C, remove the low boilers in vacuum, continue to adjust the reaction temperature of the system to 150 ° C and slowly pass Inject 500.0 grams of ethylene oxide, and control the pressure to ≤0.60MPa. After the reaction, neutralize and dehydrate after cooling to obtain C 16 h 33 O(CHCH 3 CH 2 O) 10 (CH 2 CH...

Embodiment 3

[0059] The preparation of composition HF-3, preparation steps:

[0060] (1) Long-chain polyether nitrogen-containing compound (C 14 h 29 OCHCH 3 CH 2 O(CH 2 CH 2 O) 30 CH 2 CH 2 N(C 3 h 7 O) 2 C 5 h 11 Br) synthesis and preparation:

[0061] Add 107.0 grams of myristyl alcohol and 3.0 grams of potassium hydroxide to a pressure reactor equipped with a stirring device, and when heated to 80-90°C, open the vacuum system, dehydrate under high vacuum for 1 hour, and then replace with nitrogen for 3- 4 times, adjust the reaction temperature of the system to 150°C and slowly pass in 60 grams of propylene oxide, control the pressure ≤ 0.60MPa, cool down to 90°C, remove the low boilers in vacuum, continue to adjust the reaction temperature of the system to 150°C and slowly pass through Inject 700.0 grams of ethylene oxide and control the pressure to ≤0.60MPa. After the reaction, neutralize and dehydrate after cooling to obtain C 14 h 29 OCHCH 3 CH 2 O(CH 2 CH 2 O) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com