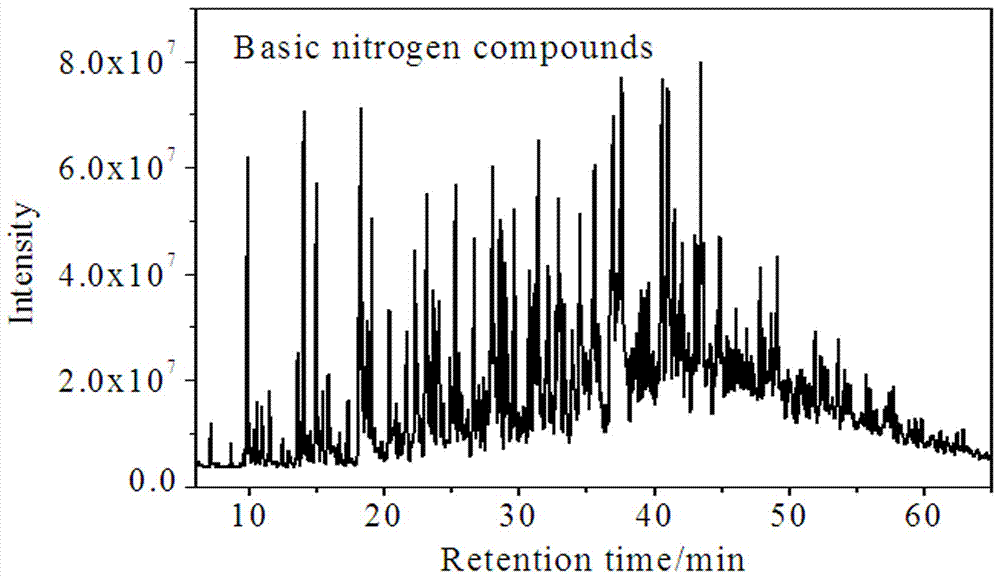

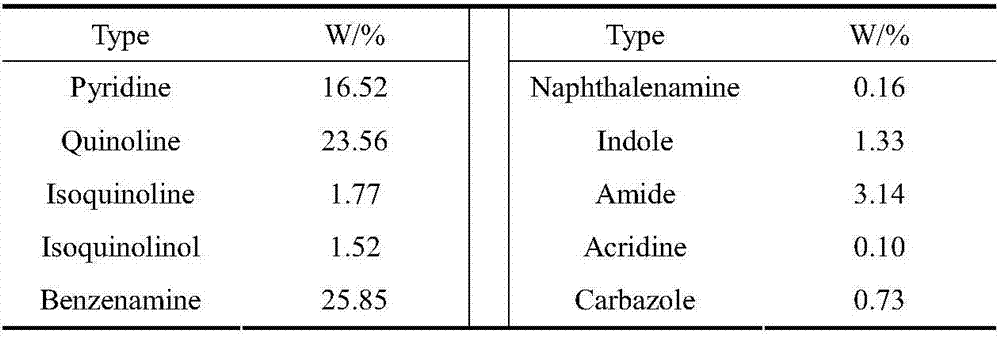

A method for the enrichment and separation of basic nitrogen compounds in shale diesel oil

A technology for shale diesel oil and nitrogen compounds, which is applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil processing products, etc., to achieve the effects of simple and feasible operation, lower production cost, and favorable processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

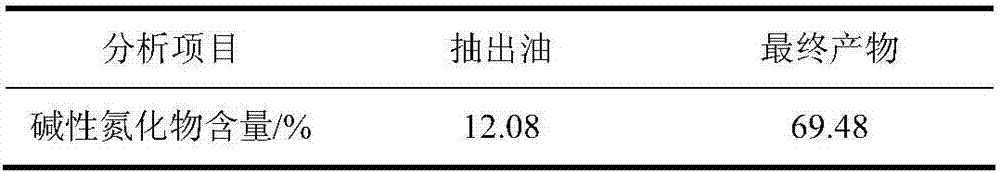

Embodiment 1

[0025] Mix 90ml of N,N-dimethylformamide with 300ml of shale diesel (the molar ratio is 0.3:1), heat and stir in a water bath, set the heating temperature to 50°C, and pour it into a separatory funnel after stirring The sample was separated into layers, and after standing for 10 minutes, the oil product in the lower layer was distilled to obtain extracted oil and N,N-dimethylformamide, and N,N-dimethylformamide was recycled. The extracted oil was separated by column chromatography, 50g of silica gel was weighed, and chromatographically eluted with 80mL of petroleum ether and 80mL of benzene / methanol mixed solution (1:1 by volume) in sequence. The obtained benzene / methanol eluate was extracted 3 times with water to separate the benzene layer solution, then extracted the benzene layer solution with 3mol / L HCl to obtain the inorganic layer, and neutralized the inorganic layer with 6mol / L NaOH solution to PH = 11, then adding n-hexane for extraction three times, extracting the bas...

Embodiment 2

[0027] Mix the extractant dimethyl sulfoxide and shale diesel at a molar ratio of 0.5:1 for a stirring reaction. The stirring reaction temperature is 50°C. After standing and settling for 20 minutes, the oil product is divided into two layers. Recover by vacuum distillation and recycle; the lower layer removes the extractant to obtain the extracted oil that is initially enriched with basic nitrogen compounds; the extracted oil is concentrated and separated by column chromatography, acid extraction of basic compounds, alkali neutralization of acid, and solvent back extraction Basic nitrides, solvent removal, and vacuum drying to obtain basic nitrides. The column chromatography solid adsorbent is silica gel; the column chromatography mobile phase is petroleum ether, benzene / methanol mixed solution; the volume ratio of benzene / methanol mixed solution is 1:1; other steps are the same as in Example 1.

Embodiment 3

[0029] The extraction agent N-methylpyrrolidone and shale diesel are mixed in a molar ratio of 1:1 for stirring reaction. The stirring reaction temperature is 70°C. After standing for 50 minutes, the oil product is divided into two layers. Recover by vacuum distillation and recycle; the lower layer removes the extractant to obtain the extracted oil that is initially enriched with basic nitrogen compounds; the extracted oil is concentrated and separated by column chromatography, acid extraction of basic compounds, alkali neutralization of acid, and solvent back extraction Basic nitrides, solvent removal, and vacuum drying to obtain basic nitrides. The column chromatography solid adsorbent is silica gel; the column chromatography mobile phase is petroleum ether, benzene / methanol mixed solution; the volume ratio of benzene / methanol mixed solution is 1.2:1; other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com