Preparation method for patterned film with gradually changed thickness

A patterned thin film and pattern technology, which is applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of complex process, obvious step effect, increased difficulty of preparation, etc., and achieve flexible operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

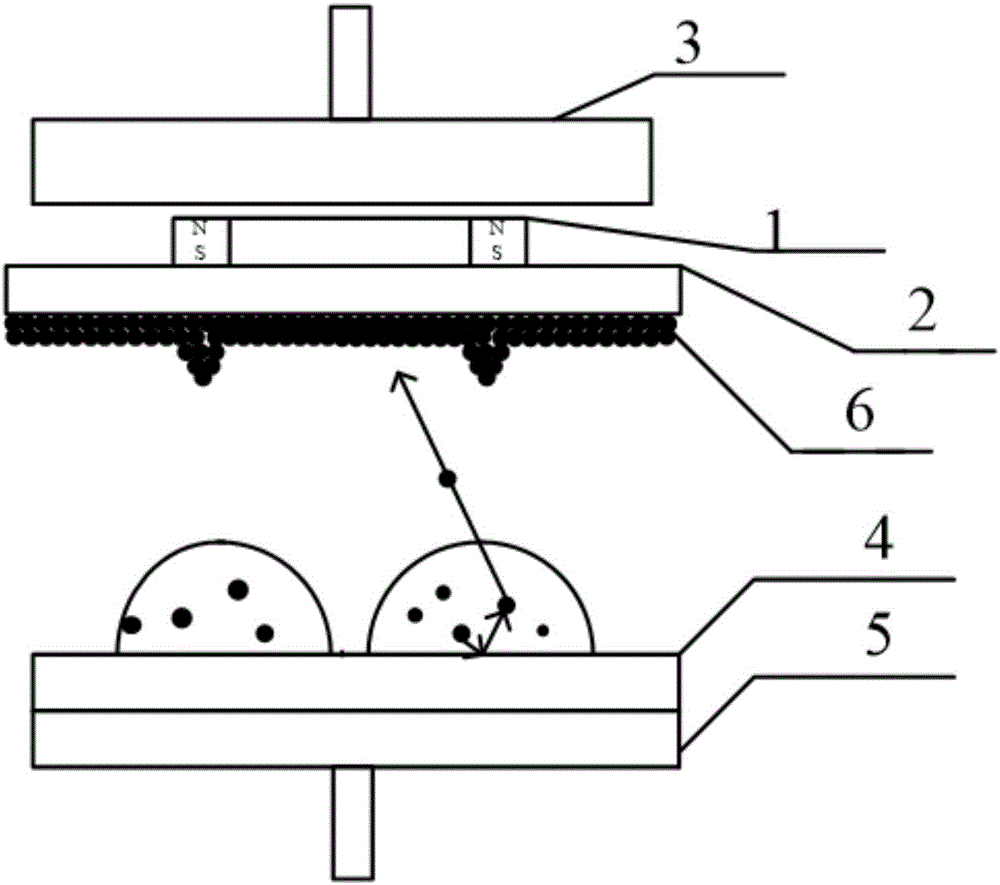

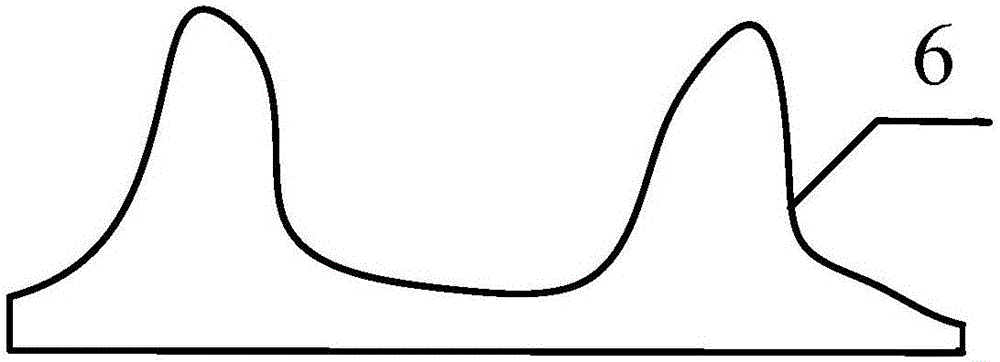

[0021] First use ANSYS finite element analysis to design and simulate the magnetic field, select the module, and determine the shape of the magnet as a ring magnet, the inner and outer diameters are 70mm and 80mm, the height of the magnet is 20mm, the magnetization of the ring magnet is 750kA / m, and the direction is along Z Axis positive. Except for the ring, the other areas are air. The boundary conditions were set, and the magnetic field distribution on the plane at a distance of 1.5 mm from the magnet was obtained after meshing; the magnetic field was constructed according to the magnetic field simulation results. Such as figure 1 As shown, select ring magnet 1 in the present embodiment, inner and outer diameters are respectively 70mm, 80mm, and magnet height is 10mm, and substrate is the quartz glass sheet 2 that surface flatness is less than 0.4nm, thickness 1.5mm, uses respectively acetone, ethanol, The substrates were ultrasonically cleaned with deionized water, and t...

Embodiment 2

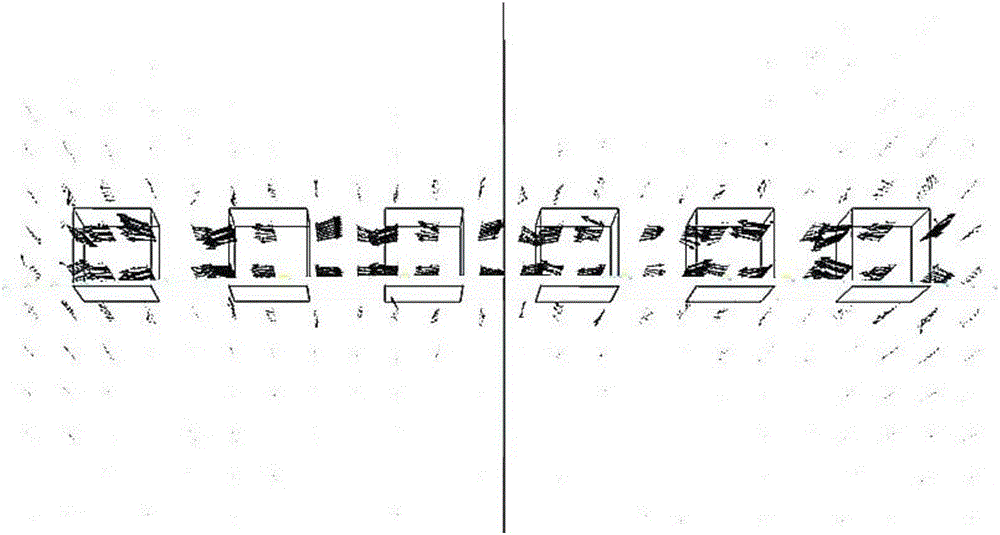

[0023] First use ANSYS finite element analysis to design and simulate the magnetic field, select the module, and determine that the shape of the magnet is a bar magnet. In this embodiment, the bar magnets with the same length, width and height are designed to be placed at equal intervals. The magnet is 10mm wide and 50mm high. The magnitude of the magnetization is 750kA / m, and the direction is along the positive direction of the Z axis. Except for the bars, the other areas are all air. Set the boundary conditions, and obtain the magnetic field distribution on the plane 1.5mm away from the magnet after meshing as image 3 shown; the magnetic field is constructed according to the magnetic field simulation results. Soft magnets have great toughness and high plasticity, and can be arbitrarily combined into desired graphics according to needs. In this example, for convenience of description, a bar magnet 8 with a simple magnetic field pattern is used. Place the strip-shaped sof...

Embodiment 3

[0025] First, use COMSOL finite element analysis to design and simulate the magnetic field, select the module, and determine that the shape of the magnet is cylindrical, with a diameter of 10mm and a height of 20mm. The arrangement of the three magnets is as follows Figure 5 As shown, the magnetization intensity is set to 750kA / m, and the direction is along the positive direction of the Z axis. Except cylinder 9, other areas are all air. After meshing, the magnetic field distribution on the plane at a distance of 1.5 mm from the magnet is obtained; the magnetic field is constructed according to the magnetic field simulation results. In this embodiment, three cylindrical magnets are selected to form a combined magnetic field that interferes with each other. Make sure that the bottom surface of the cylinder is on the same level and in close contact with the upper surface of the substrate, and then fix the placed magnet substrate on the positive sample stage of the magnetron sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com