A slotting device for adding dowel bars at the joints of cement concrete pavement blocks

A grooving equipment and joint technology, applied in the field of fast and efficient grooving construction equipment, can solve the problems of complex grooving process, inconvenient operation and high labor cost, and achieve the effect of clear principle, convenient operation and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

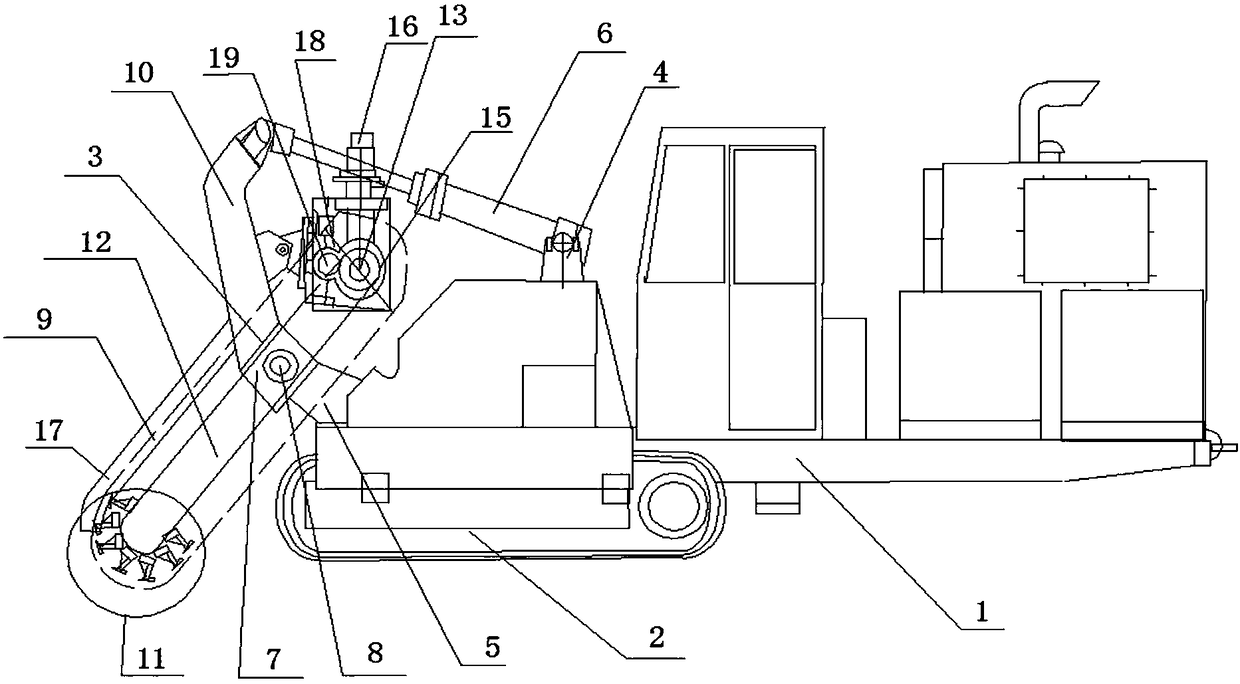

[0040] Embodiment 1: as figure 1 As shown, this embodiment takes one piece of equipment controlling a group of grooving and cutting devices as an example.

[0041] A slotting device for adding dowel bars at the joints of cement concrete pavement blocks, comprising a frame 1, a running device 2 and a slotting device 3, the running device 2 and the slotting device 3 are fixedly installed on the machine On the frame 1, it is characterized in that the slotting device 3 includes a first support 4, a second support 5, and a hydraulic cylinder 6, the first support 4 is located at the top of the frame 1, and the hydraulic cylinder 6 is fixed Installed on the first support 4; the second support 5 is located at the front end of the frame 1; Device 9; the support sleeve 8 is located in the middle of the slotting cutting device 9, the square support plate 7 is fixedly installed with an arc-shaped support arm 10 for adjusting the depth of the slot, and the support arm 10 is connected with...

Embodiment 2

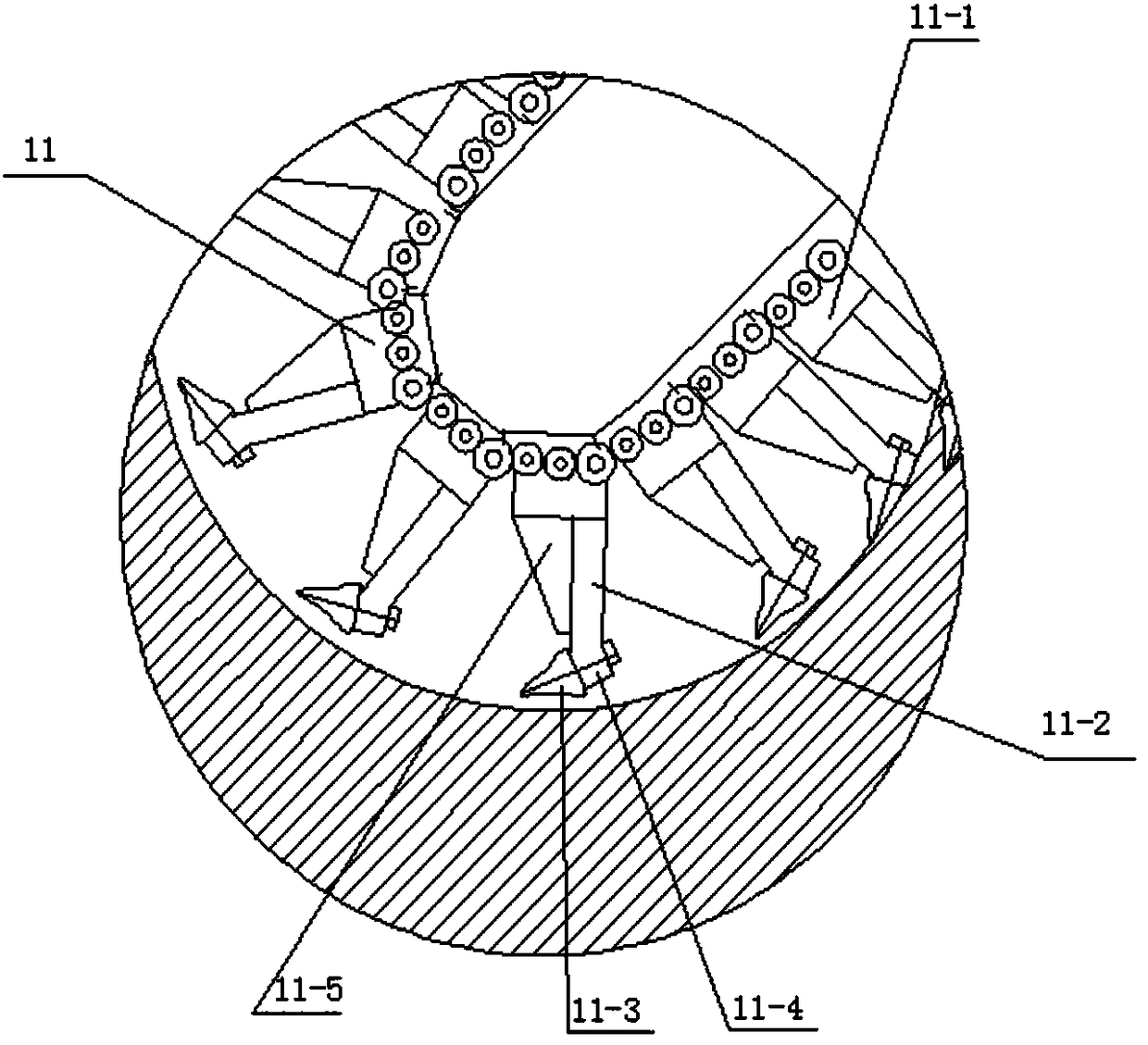

[0047] Embodiment 2: The high-efficiency slotting equipment for adding dowel bars at the joints of cement concrete road slabs in this embodiment is a further optimization of the above embodiment, the only difference is that the tapered milling head 11-3 and the tool holder 11 -2 is an obtuse angle, and the size of the obtuse angle is between 100-150°, so that the conical milling head 11-3 is in closer contact with the cement concrete, and the end of the conical milling head 11-3 is ring-shaped Gathering the concave design inwards can ensure that the chain milling mechanism 11 is more labor-saving in the process of slotting, improves the wear resistance of the conical milling head 11-3, and prolongs the life of the chain milling mechanism 11 slotting.

Embodiment 3

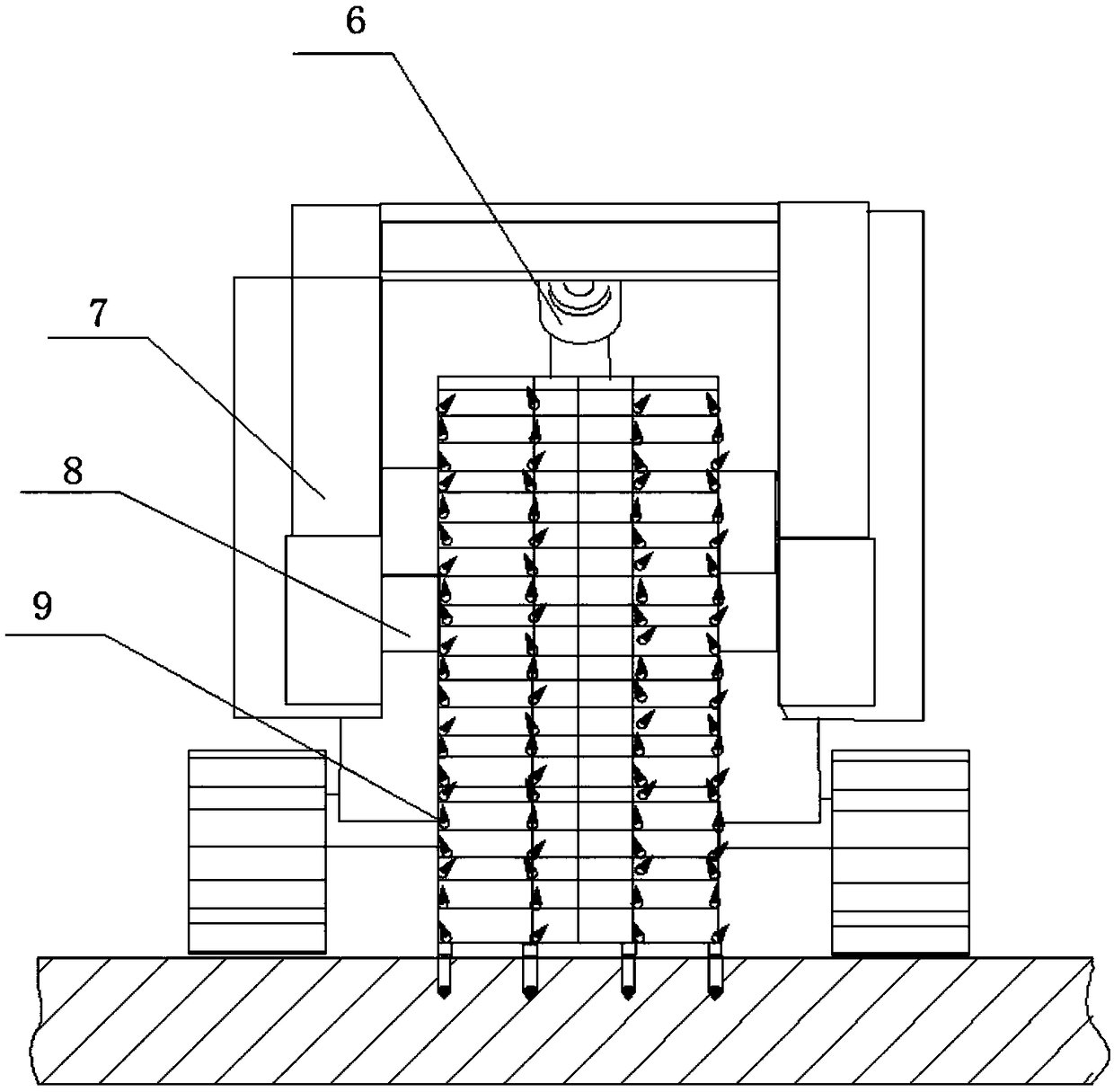

[0048] Embodiment 3: as figure 2 As shown, this embodiment takes one device controlling four sets of grooving and cutting devices as an example.

[0049] A slotting device for adding dowel bars at the joints of cement concrete pavement blocks includes four sets of slotting cutting devices 9, and the slotting cutting devices 9 are fixedly installed on the support sleeve 8 at equal distances and with adjustable distances , the second support 5 is connected to the middle part of the support sleeve 8, the side of the square support plate 7 perpendicular to the slotting cutting device 9 is fixedly connected to the support arm 10, and the four sets of slotting cutting devices 9 Slotted drive sprocket 15 shares a power main shaft 13, drives power main shaft 13 to rotate by driving device 18 through gear drive 19, thereby drives chain type milling mechanism 11 to run synchronously on respective guide beam 12 respectively; It is connected with the middle part of the power spindle 13,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com