Cement rotary kiln mouth refractory construction method

A cement rotary kiln and construction method technology, applied in the field of refractory materials, can solve problems such as bursting and castable damage, and achieve the effects of avoiding bursting, large construction space, and improving compactness and erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

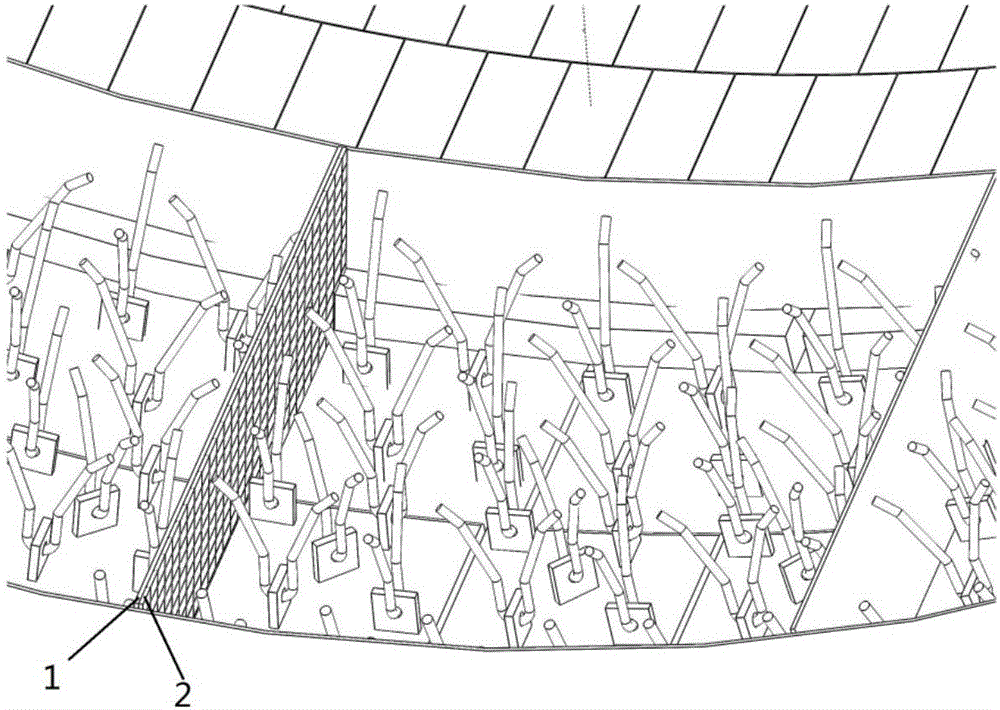

[0034] The present invention will be further described below in conjunction with embodiment and accompanying drawing, cement rotary kiln kiln mouth back iron quantity 54, each mold comprises 3 back irons.

[0035] The cement rotary kiln pouring material construction method of the present invention comprises the following steps:

[0036] 1. Anchor welding

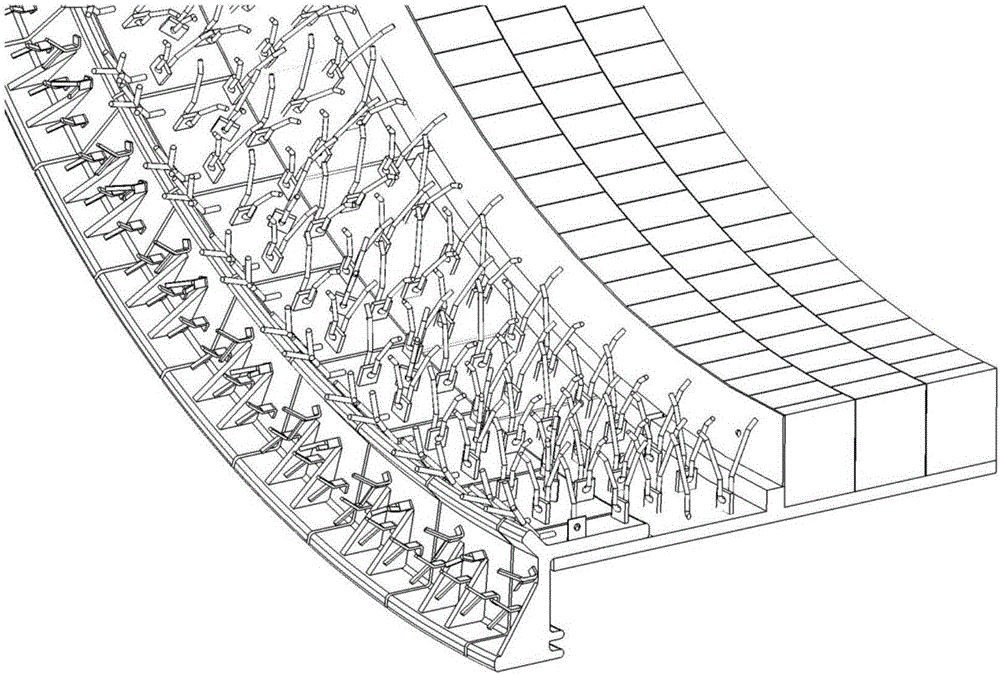

[0037] 1) For anchor arrangement, see figure 1 , the anchor piece does not cross the kiln back guard iron gap and its extension line;

[0038] 2) Check the shell of the rotary kiln, and remove the oxide layer on the surface of the shell of the cement rotary kiln, so as to avoid the failure of the anchor due to desoldering due to weak welding of the anchor;

[0039] 3) The spacing between anchors is 150mm;

[0040] 4) The head of the anchor is wrapped with a plastic tape with a thickness of 2mm;

[0041] 5) A302 welding rods should be used for the welding of anchors, and the full welding method should be used for welding....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com