Preparation method and application of INP resistive memory material

A resistive variable storage and equipment technology, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems such as the difficulty of process implementation and will not be quickly promoted, and achieve improved defect status, high durability, and improved The effect of shift consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

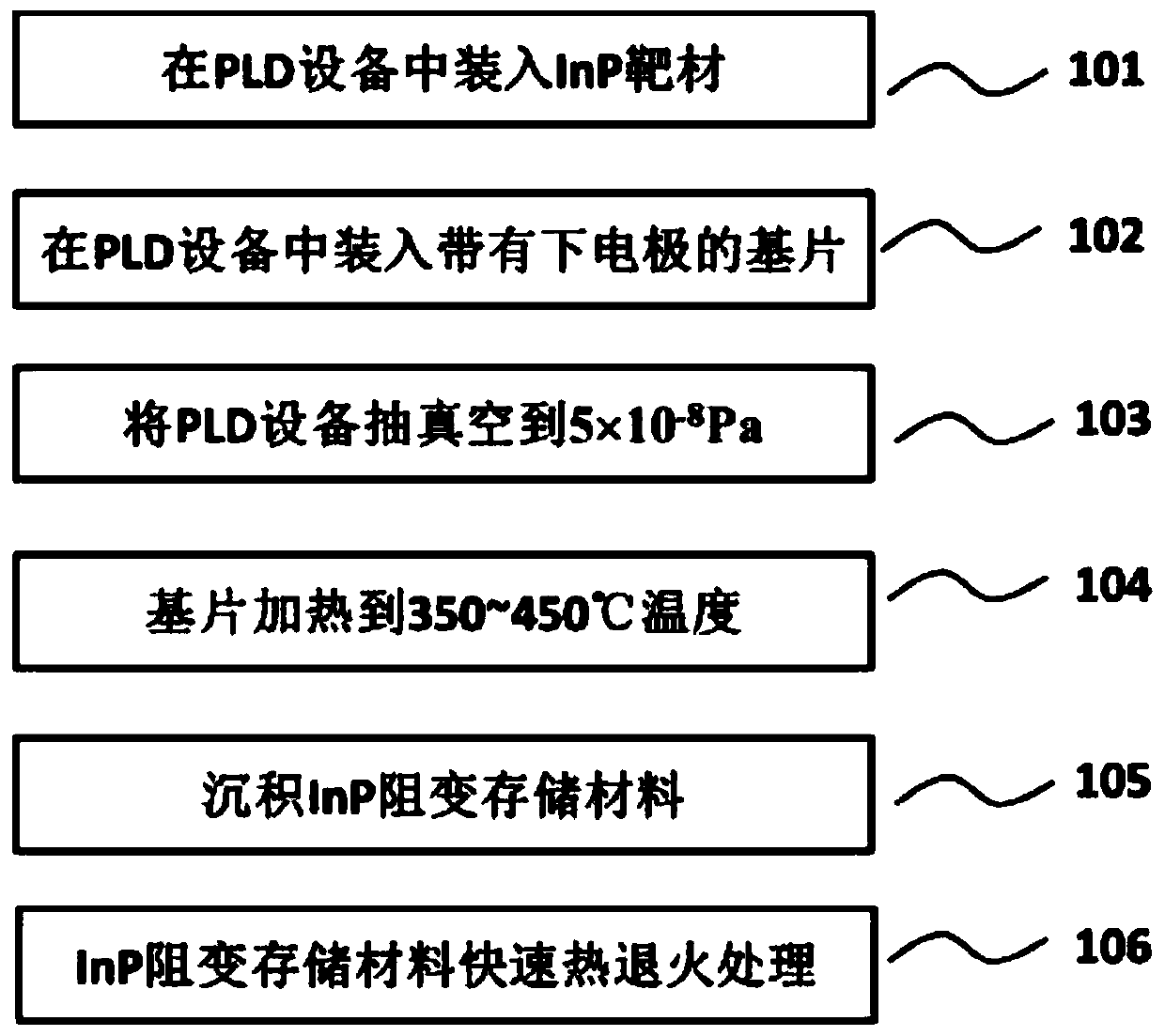

[0024] figure 1 Flowchart for the preparation method of InP resistive memory material:

[0025] Step 101: loading a single crystal InP sheet as a target into a cavity of a pulsed laser device;

[0026] Step 102: loading the substrate with electrodes deposited on the surface into the cavity of the pulsed laser device;

[0027] Step 103: Vacuumize the cavity of the pulsed laser equipment to 5×10 -8 Pa;

[0028] Step 104: heating the substrate to 350-450°C;

[0029] Step 105: Depositing an InP thin film on the substrate by means of pulsed laser deposition;

[0030] Step 106: performing rapid thermal annealing on the substrate deposited with the InP thin film at 600-800° C. for 5-120 seconds to obtain an InP resistive memory material.

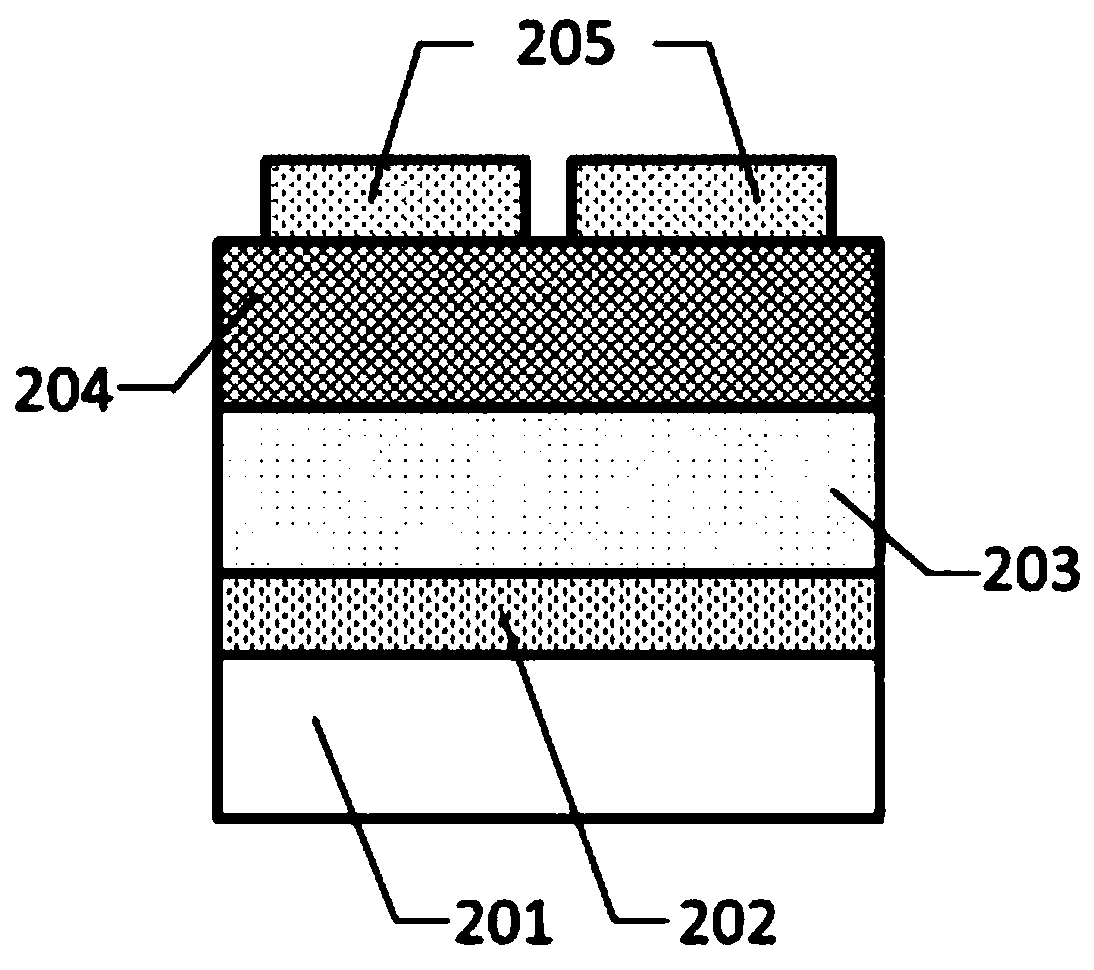

[0031] figure 2 It is a schematic structural diagram of a resistive memory device prepared based on InP resistive memory material, specifically: substrate material 201, the substrate material is single crystal silicon, and there is a silicon...

Embodiment 1

[0033] The preparation method and application of InP resistive memory materials, specifically including:

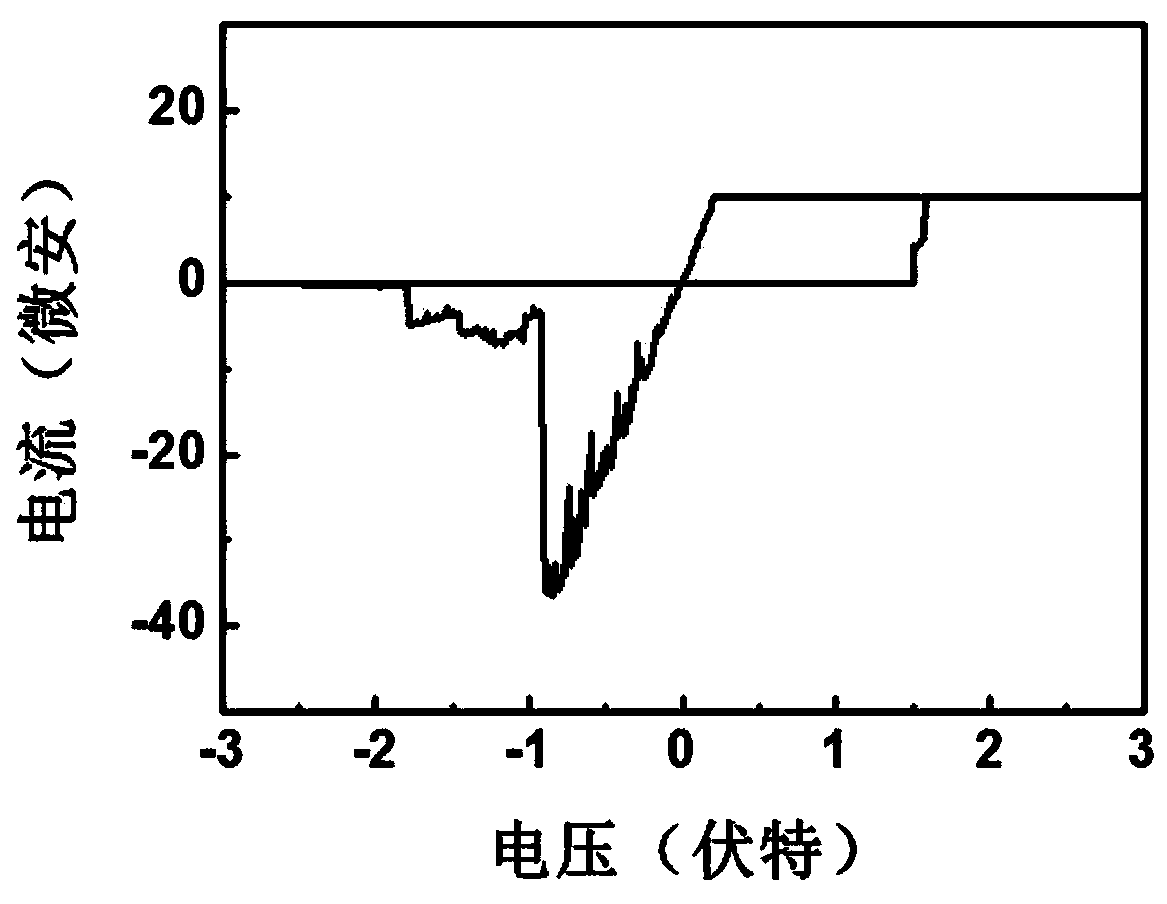

[0034] 1) The preparation method of the InP resistive memory material, the preparation steps are as follows: the InP target is fixed on the target holder of the PLD cavity, and then the Si / SiO with Pt / Ti electrodes deposited on the surface 2 Put the substrate into the sample holder in the cavity of the pulsed laser equipment, adjust the distance between the target substrates to 7cm, and then use the molecular pump to vacuum the cavity of the PLD equipment to 5×10 -8 Pa, use an electric furnace wire to heat the sample holder to 400°C, use a KrF excimer laser with a wavelength of 248nm as the laser source, set the laser parameters as follows: pulse frequency 5Hz, single pulse energy 240mJ, energy density 1.8J / cm 2 , and then start the laser to start depositing the InP resistive memory material on the substrate. The deposition time is 20 minutes, and the thickness of the InP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com