A preparation method of transparent conductive oxide film-nanowire network

An oxide thin film, transparent and conductive technology, applied in the field of optoelectronic technology and new energy materials, can solve the problems of many oxygen defects in nanowires, difficult to control the length of the region where nanowires grow, and unable to independently control the position and size of catalysts. The effect of high resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

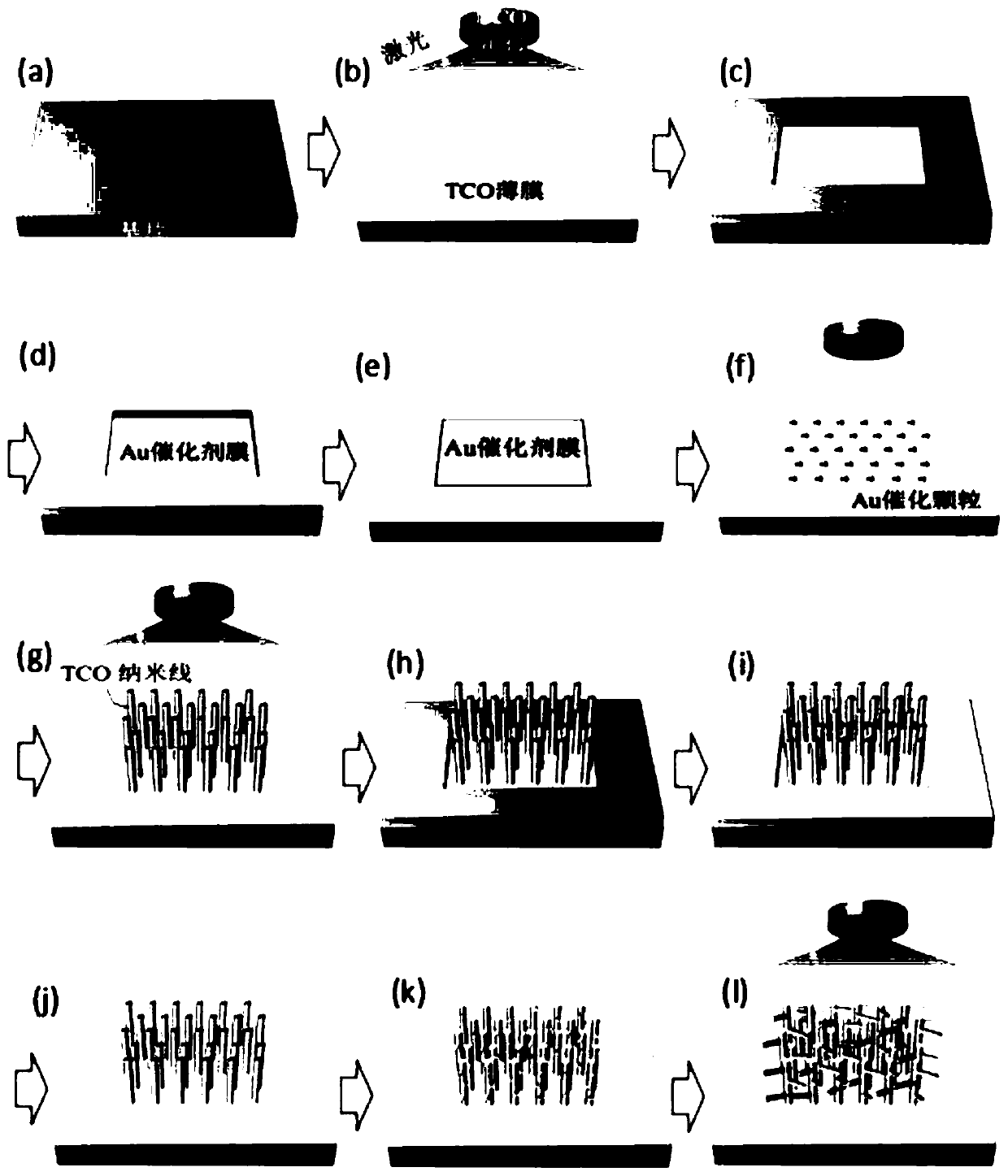

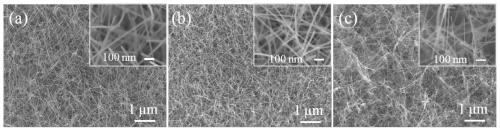

Method used

Image

Examples

Embodiment 1

[0037] Step 1, transparent conductive oxide film growth:

[0038] The transparent substrate (material: ordinary glass) is ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, and after drying with nitrogen, it is treated with ultraviolet and ozone (150W ultraviolet lamp, treated in air for 10 minutes);

[0039] Place the cleaned substrate into the pulsed laser deposition chamber at 10 -3 Under the oxygen atmosphere of Pa, the substrate was heated to 100°C, the energy of the krypton fluoride excimer laser was controlled to be 20mJ, the repetition frequency was 2Hz, and the transparent conductive oxide target (FTO) was sputtered for 10min, and the surface of the substrate grew Transparent conductive oxide film, the thickness of the transparent conductive oxide film is 50nm;

[0040] Step 2, gold catalyst film deposition: take out the substrate with the transparent conductive oxide film deposited on the surface in step 1, and stick a metal mask on t...

Embodiment 2

[0044] Step 1, transparent conductive oxide film growth:

[0045] The transparent substrate (material: alumina single crystal) is ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, and after drying with nitrogen, it is treated with ultraviolet and ozone (150W ultraviolet lamp, treated in air for 10 minutes);

[0046] Place the cleaned substrate into the pulsed laser deposition chamber at 10 -1 Under the oxygen atmosphere of Pa, the substrate was heated to 350°C, the energy of the krypton fluoride excimer laser was controlled to be 60mJ, the repetition frequency was 10Hz, and the transparent conductive oxide target (ITO) was sputtered for 60min, and the surface of the substrate grew Transparent conductive oxide film, the thickness of the transparent conductive oxide film is 400nm;

[0047] Step 2, gold catalyst film deposition: take out the substrate with the transparent conductive oxide film deposited on the surface in step 1, and stick a metal...

Embodiment 3

[0051] Step 1, transparent conductive oxide film growth:

[0052] The transparent substrate (material: quartz glass) is ultrasonically cleaned with acetone, isopropanol, and deionized water in sequence, and after drying with nitrogen, it is treated with ultraviolet and ozone (150W ultraviolet lamp, treated in air for 10 minutes);

[0053] Place the cleaned substrate into the pulsed laser deposition chamber at 10 -2 Under the oxygen atmosphere of Pa, the substrate was heated to 300°C, the energy of the krypton fluoride excimer laser was controlled to be 40mJ, the repetition frequency was 10Hz, and the transparent conductive oxide target (FTO) was sputtered for 30min, and the surface of the substrate grew Transparent conductive oxide film, the thickness of the transparent conductive oxide film is 300nm;

[0054] Step 2, gold catalyst film deposition: take out the substrate with the transparent conductive oxide film deposited on the surface in step 1, and stick a metal mask on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com