SrFeOx resistive random access memory with multi-valued characteristic as well as preparation and application of SrFeOx resistive random access memory

A resistive memory and characteristic technology, applied in the field of semiconductor information storage, can solve problems such as limiting the storage capacity of devices, and achieve the effect of increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

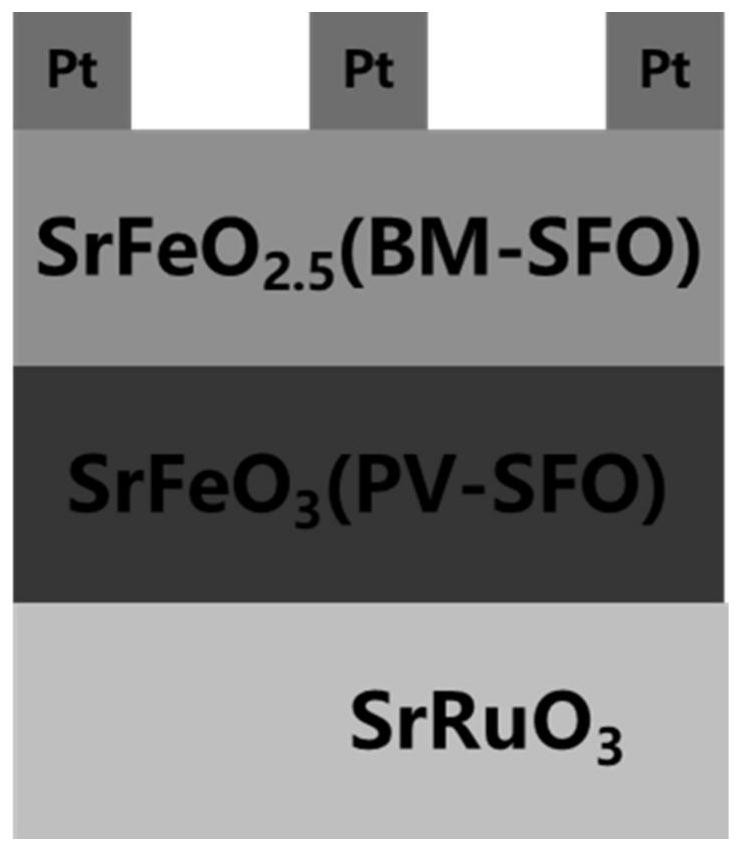

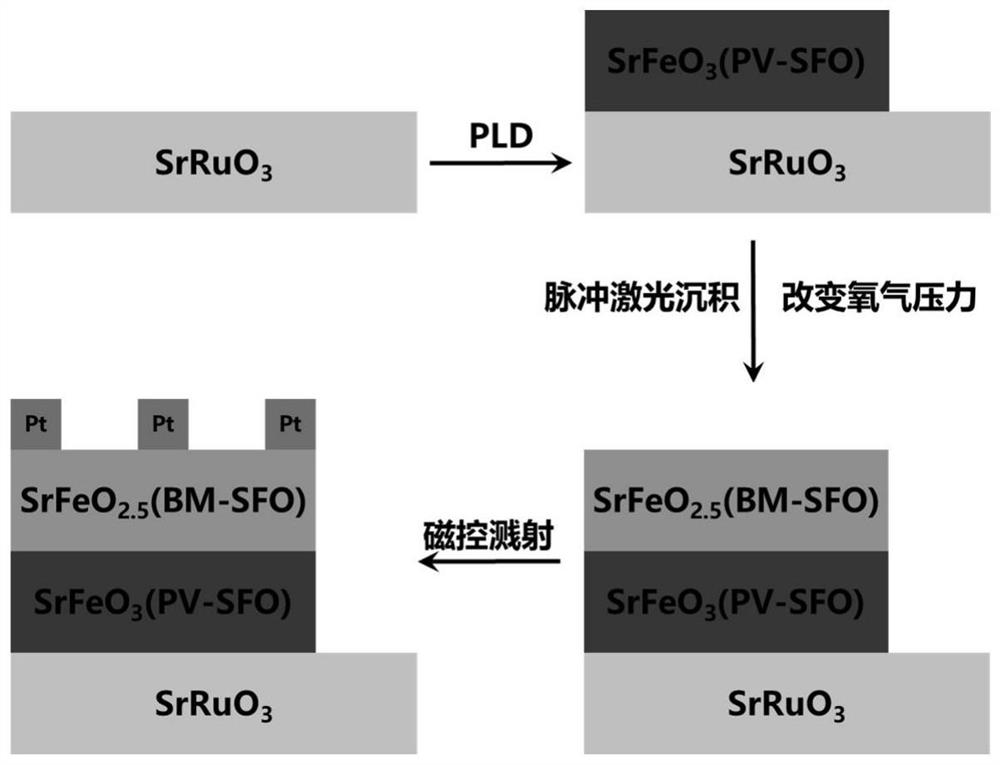

[0040] The present invention also provides the preparation method of the resistive memory device, comprising the following steps:

[0041] (1) The lower electrode and the first variable resistance layer SrFeO are sequentially deposited on the cleaned substrate using a pulsed laser deposition process. m Thin films, where 2.7≤m≤3;

[0042] (2) Using a pulsed laser deposition process on the first variable resistance layer SrFeO m Deposition of the second variable resistance layer SrFeO on the surface of the film 2.5 film;

[0043] (3) Magnetron sputtering and photolithography are used in the second resistance change layer SrFeO 2.5 The top electrode is prepared by deposition on the surface of the thin film.

[0044] In some embodiments, the process conditions of the pulsed laser deposition in step (1): the temperature is 650-700°C, the cavity atmosphere is oxygen, the air pressure is 3-10Pa, the laser energy is 250-450mJ, and the laser frequency is 1-8Hz , the vacuum degree ...

Embodiment 1

[0048] (1) Ultrasonic cleaning of SrTiO in acetone, ethanol, deionized water 3 15 minutes for each substrate;

[0049] (2) Use pulsed laser deposition to prepare SrRuO on the substrate described in step (1) 3 For the lower electrode, the process conditions are as follows: temperature is 680°C, chamber atmosphere is oxygen, air pressure is 10Pa, laser energy is 250mJ, laser frequency is 4Hz, vacuum degree is 5×10 -6 Pa, the distance between substrate and target is 55mm; SrRuO 3 The film thickness is 50 nm.

[0050] (3) Prepare SrFeO on the lower electrode described in step (2) using pulsed laser deposition 3 Thin film, the process conditions are: temperature is 650°C, chamber atmosphere is oxygen, air pressure is 5Pa, laser energy is 250mJ, laser frequency is 4Hz, vacuum degree is 5×10 -6 Pa, the distance between the lower electrode and the target is 55mm; SrFeO 3 The film thickness is 40 nm.

[0051] (4) SrFeO after completion of step (3) 3 Preparation of SrFeO by chang...

Embodiment 2

[0054] (1) Ultrasonic cleaning of SrTiO in acetone, ethanol, deionized water 3 15 minutes for each substrate;

[0055] (2) Use pulsed laser deposition to prepare SrRuO on the substrate described in step (1) 3 For the lower electrode, the process conditions are as follows: temperature is 680°C, chamber atmosphere is oxygen, air pressure is 10Pa, laser energy is 250mJ, laser frequency is 4Hz, vacuum degree is 5×10 -6 Pa, the distance between substrate and target is 55mm; SrRuO 3 The film thickness is 50 nm.

[0056] (3) Prepare SrFeO on the lower electrode described in step (2) using pulsed laser deposition 3 Thin film, the process conditions are: temperature is 650°C, chamber atmosphere is oxygen, air pressure is 5Pa, laser energy is 250mJ, laser frequency is 4Hz, vacuum degree is 5×10 -6 Pa, the distance between the lower electrode and the target is 55mm, SrFeO 3 The film thickness is 50nm;

[0057] (4) SrFeO after completion of step (3) 3 Preparation of SrFeO by changi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com