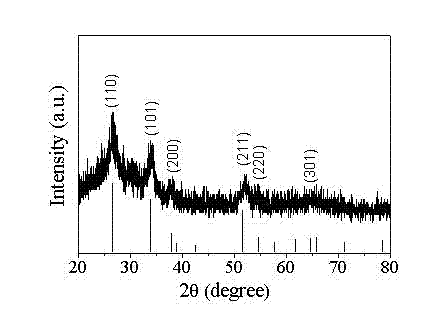

Method for preparing controllable ordered porous tin dioxide nano structures

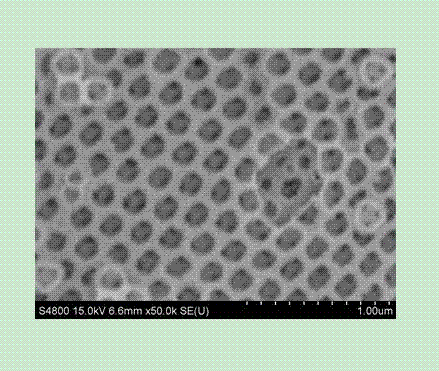

A technology of tin dioxide and nanostructures, applied in the direction of tin oxide, etc., can solve the problems of difficult controllable and orderly porous tin dioxide nanostructures, harsh preparation and operating conditions, and limitations in the application of tin dioxide, and achieve high morphology Orderly, effective control of three-dimensional depth, and effective control of hole wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The medicaments or reagents involved in the present invention are all analytically pure.

[0021] 8.75g of SnCl 4 4H 2 O was added to 100ml of absolute ethanol solution, heated to 80°C by a magnetic stirrer, kept at a constant temperature of 80°C in a water bath for 10h, and the rotor speed was 500r / min. Then it was cooled to room temperature and left to stand for 24 hours for aging treatment to obtain a tin dioxide sol solution.

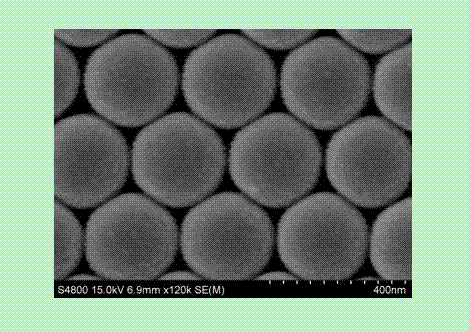

[0022] Add 0.9g of styrene into 70ml of deionized water, heat it to 70°C with a magnetic stirrer and water bath, and set the solution as A solution. 0.115g of K 2 S 2 o 8 Add it into 5ml deionized water and sonicate for 20-30min, and set this solution as B solution. After keeping solution A at 70°C for 20 minutes, slowly drop into solution B under the action of a magnetic stirrer at a speed of 300 r / min. After the dropwise addition, keep at 70°C for 24 hours to obtain polystyrene pellets. The prepared polystyrene pellets were formulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com