Epitaxial structure and preparation method of deep ultraviolet multi-quantum well semiconductor laser

A multi-quantum well and epitaxial structure technology, which is applied in the field of epitaxial structure growth and preparation of deep ultraviolet multi-quantum well semiconductor lasers, can solve the problems of unfavorable product progress and development, large laser volume and high cost, and achieve high photoelectric conversion efficiency , high growth quality and precise component control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

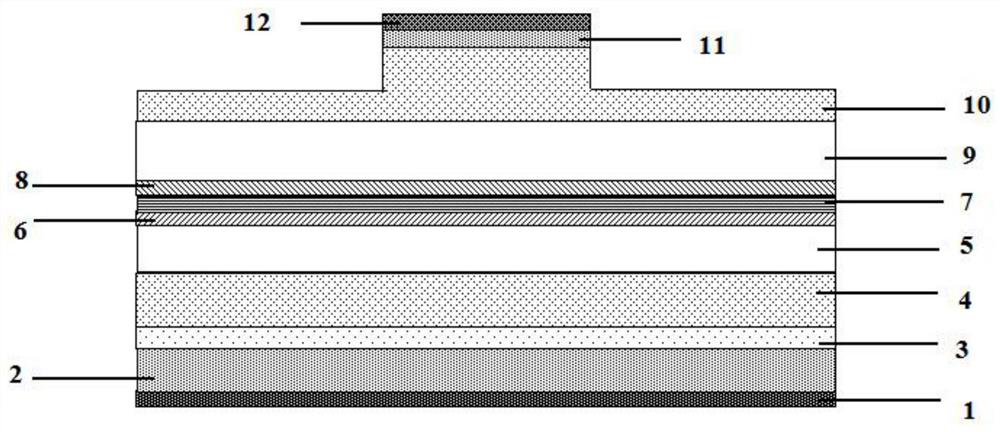

[0058] Epitaxial structure of deep ultraviolet multi-quantum well semiconductor laser: including a thickness of doping concentration 3E18cm -3 , an N-type single crystal substrate 2 with a thickness of 660 μm; an N-type transition layer 3 (thickness is 300 nm, Al x N y x / y=1-0.45 in the material, the value of x / y decreases with increasing thickness), N-type lower confinement layer 4 (thickness is 1.6 μm, Al x N y x / y=0.40 in the material), the lower waveguide layer 5 (thickness is 0.15μm, Al x N y x / y=0.55-0.7 in the material, and the x / y value increases with thickness), lower barrier layer 6 (thickness is 10nm, Al x N y x / y=0.85 in the material), multi-quantum well layer 7 (3 single quantum well layers, 2 barrier layers, a barrier layer is sandwiched between every two single quantum well layers, and the thickness of the single quantum well layer is 6.5nm, x / y=0.1, barrier layer thickness is 8nm, x / y=0.85), upper barrier layer 8 (thickness is 10nm, Al x N y x / y=0.85 in...

Embodiment 2

[0077] Epitaxial structure of deep ultraviolet multi-quantum well semiconductor laser: including a thickness of doping concentration 3E18cm -3 An N-type single crystal Si substrate 2 with a thickness of 640 μm; an N-type transition layer 3 (thickness is 500 nm, Al x N y x / y=1-0.40 in the material, the value of x / y gradually decreases with thickness), N-type lower confinement layer 4 (thickness is 2 μm, Al x N y x / y=0.40 in the material), the lower waveguide layer 5 (thickness is 0.25μm, Al x N y x / y=0.55-0.68 in the material, the x / y value increases uniformly with the thickness), the lower barrier layer 6 (thickness is 10nm, Al x N y x / y=0.83 in the material), multi-quantum well layer 7 (3 quantum well layers, thickness is 7nm, x / y=0.95, barrier layer is sandwiched between adjacent quantum well layers, barrier layer thickness is 8nm, x / y=0.85), upper barrier layer 8 (thickness is 10nm, Alx N y x / y=0.83 in the material), upper waveguide layer 9 (thickness is 0.25μm, Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com