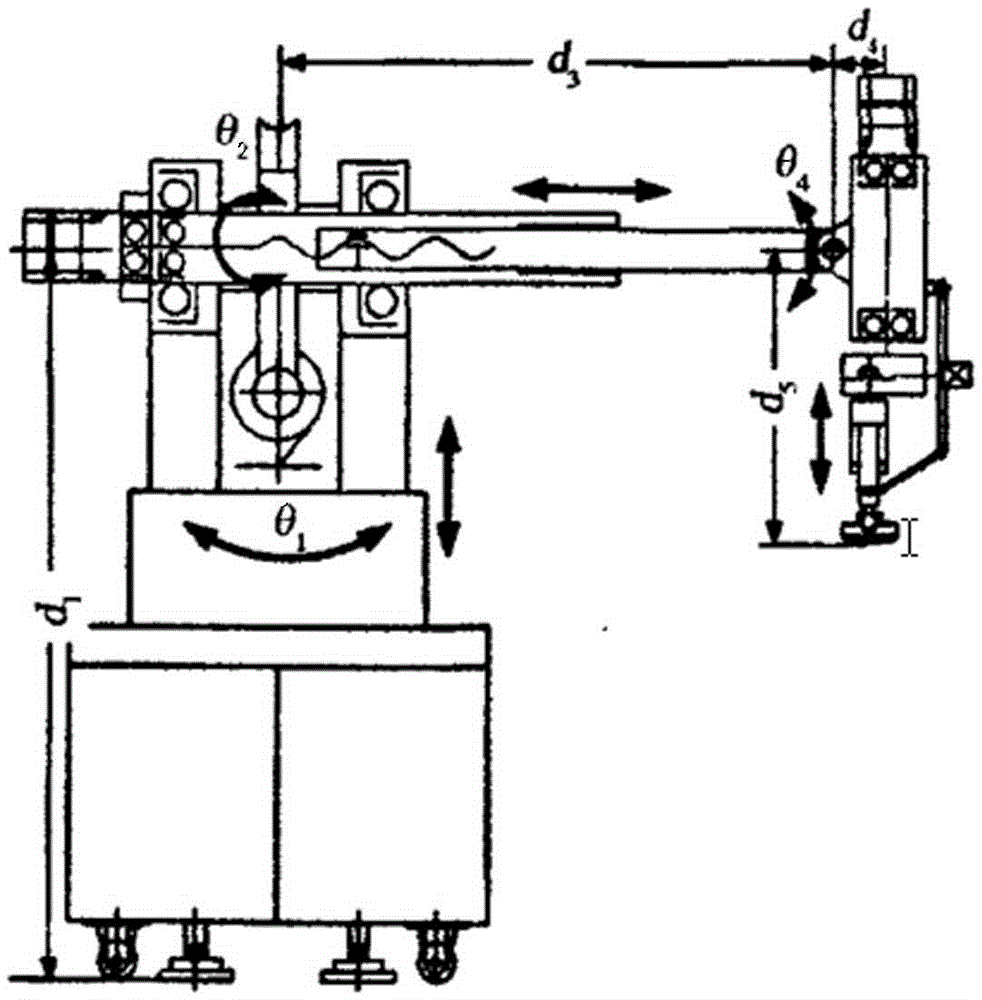

Five-degree-of-freedom polishing manipulator for large aperture optical component

An optical element and manipulator technology, applied in the field of optics, can solve the problems that restrict the development of large-scale aspheric processing technology, long processing cycle, etc., and achieve the effect of facilitating simultaneous work, small space position, simplified structure and control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

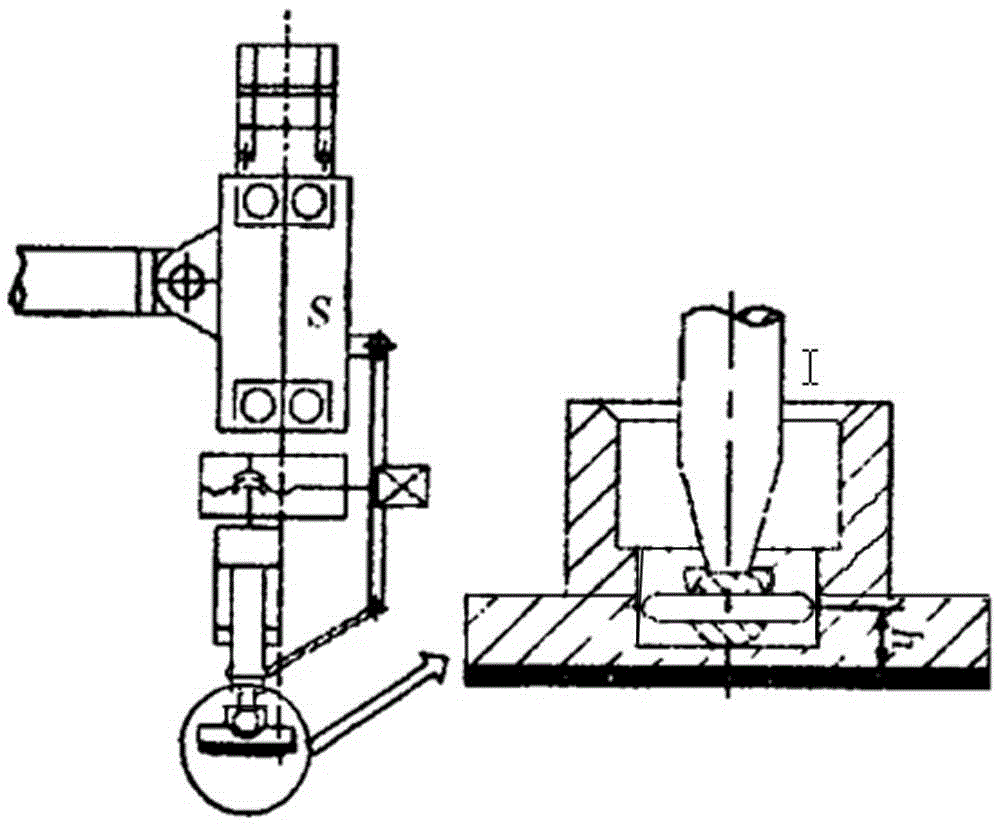

[0015] Such as figure 1 , The polishing head system of the manipulator adopts the movement mode of flat rotation, pneumatic pressure, Z-axis floating, the polishing mold and the grinding head shaft are flexibly connected by a ball hinge and a dial pin, and the screw located above the grinding head shaft can adjust the eccentricity. First of all, the translational rotation motion method can not only produce a smooth curve with a peak in the center, but also because the polishing disc translates, the gradient change of the optical surface covered by the polishing disc in one rotation cycle is the smallest, which is conducive to the coincidence between the polishing disc and the surface of the workpiece; pneumatic processing The pressure and the Z-axis float, while generating a stable polishing pressure, the polishing die changes in real time with the workpiece surface sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com