A Coupling Process of Activated Carbon-Activated Sludge

A technology of activated sludge and activated carbon, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. Long-term problems, to avoid waste of activated carbon, to facilitate sludge settlement, to reduce the effect of activated carbon loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

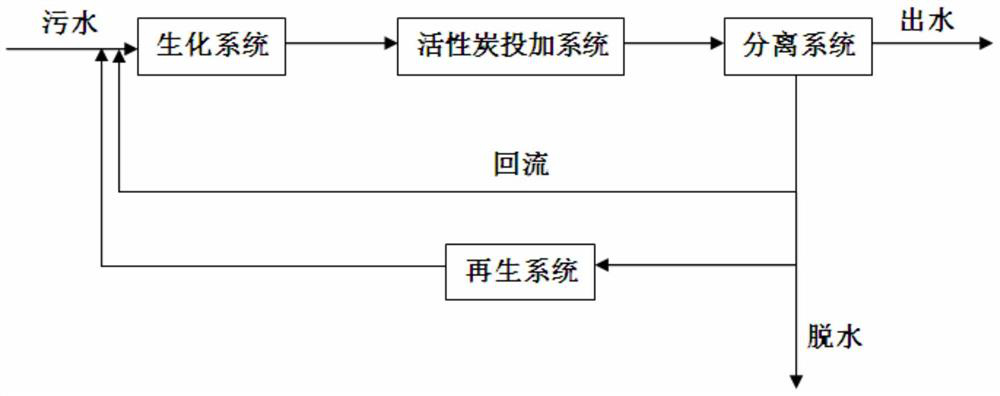

Image

Examples

Embodiment 1

[0066] This example is used to illustrate the activated carbon-activated sludge coupling process of the present invention.

[0067] (1) Sewage to be treated (COD is 700-1000mg / L, ammonia nitrogen is 30-40mg / L, sewage water temperature is 20-25°C) enters the activated sludge aeration tank for aeration treatment, and the hydraulic power of the sewage in the aeration tank The residence time is 20h;

[0068] (2) The effluent from the aeration tank enters the activated carbon dosing system, and after being exhausted by the exhaust device, the COD value detected by the COD detection device is 71mg / L. The adsorption test was carried out on the effluent of the aeration tank, and 100mg of activated carbon adsorbed 42mg of COD, so the coefficient k=2.4. According to the relationship m=k×(n-50), relative to the effluent from the aeration tank, the activated carbon dosing device adds 50mg / L of activated carbon, and the activated carbon and the effluent from the aeration tank are mixed ev...

Embodiment 2

[0074] This example is used to illustrate the activated carbon-activated sludge coupling process of the present invention.

[0075] (1) Sewage to be treated (COD is 700-1000mg / L, ammonia nitrogen is 30-40mg / L, sewage water temperature is 20-25°C) enters the activated sludge aeration tank for aeration treatment, and the hydraulic power of the sewage in the aeration tank The residence time is 12h;

[0076] (2) The effluent from the aeration tank enters the activated carbon dosing system, and after being exhausted by the exhaust device, the COD value detected by the COD detection device is 75mg / L. The adsorption test was carried out on the effluent of the aeration tank, and 100mg of activated carbon adsorbed 31mg of COD, so the coefficient k=3.2. According to the relationship m=k×(n-50), relative to the effluent of the aeration tank, the activated carbon dosing device adds 80 mg / L of activated carbon, and the activated carbon and the effluent of the aeration tank are mixed evenl...

Embodiment 3

[0081] This example is used to illustrate the activated carbon-activated sludge coupling process of the present invention.

[0082] (1) Sewage to be treated (COD is 700-1000mg / L, ammonia nitrogen is 30-40mg / L, sewage water temperature is 20-25°C) enters the activated sludge aeration tank for aeration treatment, and the hydraulic power of the sewage in the aeration tank The residence time is 8h;

[0083] (2) The effluent from the aeration tank enters the activated carbon dosing system, and after being exhausted by the exhaust device, the COD value detected by the COD detection device is 65mg / L. The adsorption test was carried out on the effluent of the aeration tank, and 100mg of activated carbon adsorbed 21mg of COD, so the coefficient k=4.8. According to the relationship m=k×(n-50), relative to the effluent of the aeration tank, the activated carbon dosing device adds 72mg / L of activated carbon, and the activated carbon and the effluent of the aeration tank are mixed evenly ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com