Method used for increasing industrial avermectin B<1a> yield via optimization of fermentation medium

A technology of fermentation medium and avermectin, which is applied in the field of fermentation biology and can solve the problem of low B1a production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1, fermentation shake flask culture

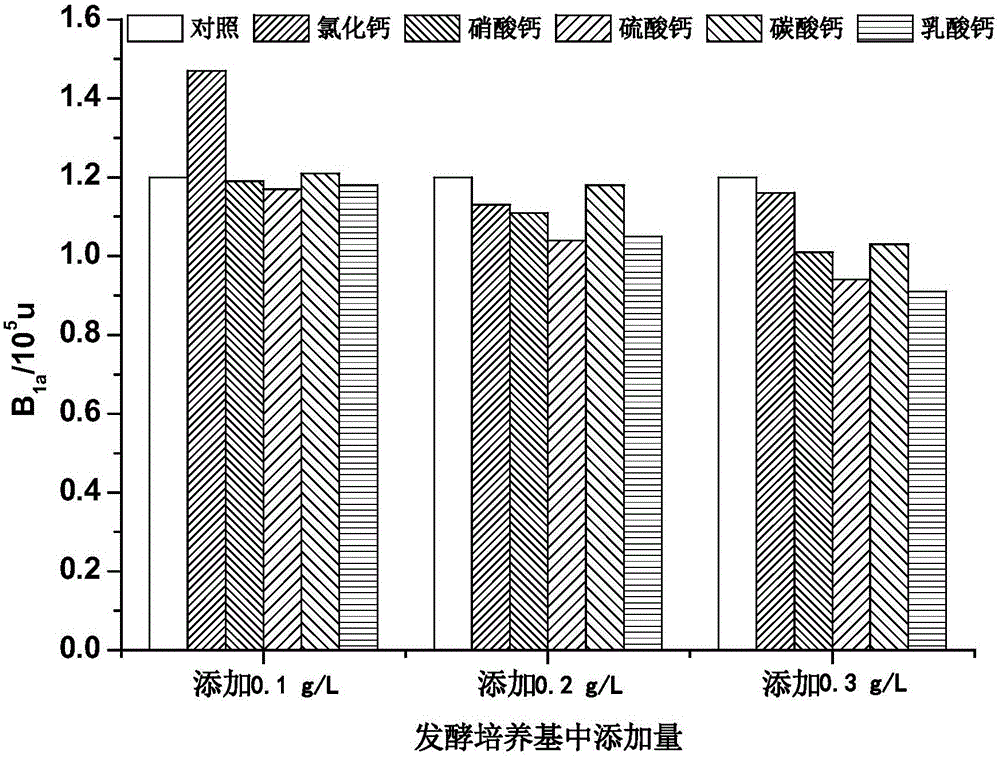

[0086] Three groups of different calcium salts with different concentrations of 0.1g / L, 0.2g / L, and 0.3g / L were added to the fermentation medium, as shown in Table 4.

[0087] Table 4. Calcium salt addition scheme

[0088]

[0089] Seed shake bottle: dig 1cm with an inoculation shovel 2 The seed slant was inoculated into the seed shaker flask for cultivation, the size of the seed shaker flask was 500ml, the filling volume was 60ml, the rotating speed of the shaker was 250rpm / min, and the cultivation was carried out at a constant temperature of 28°C for 2 days. The seed shake flask does not add calcium chloride, no induction, no stirring, no aeration.

[0090] Fermentation shake flask: take 2ml of the cultivated seed liquid from the seed shake flask and put it into the fermentation shake flask for fermentation and cultivation. The fermentation shake flask is 500ml, the liquid volume is 40ml, the shaker speed is 250rpm...

Embodiment 2

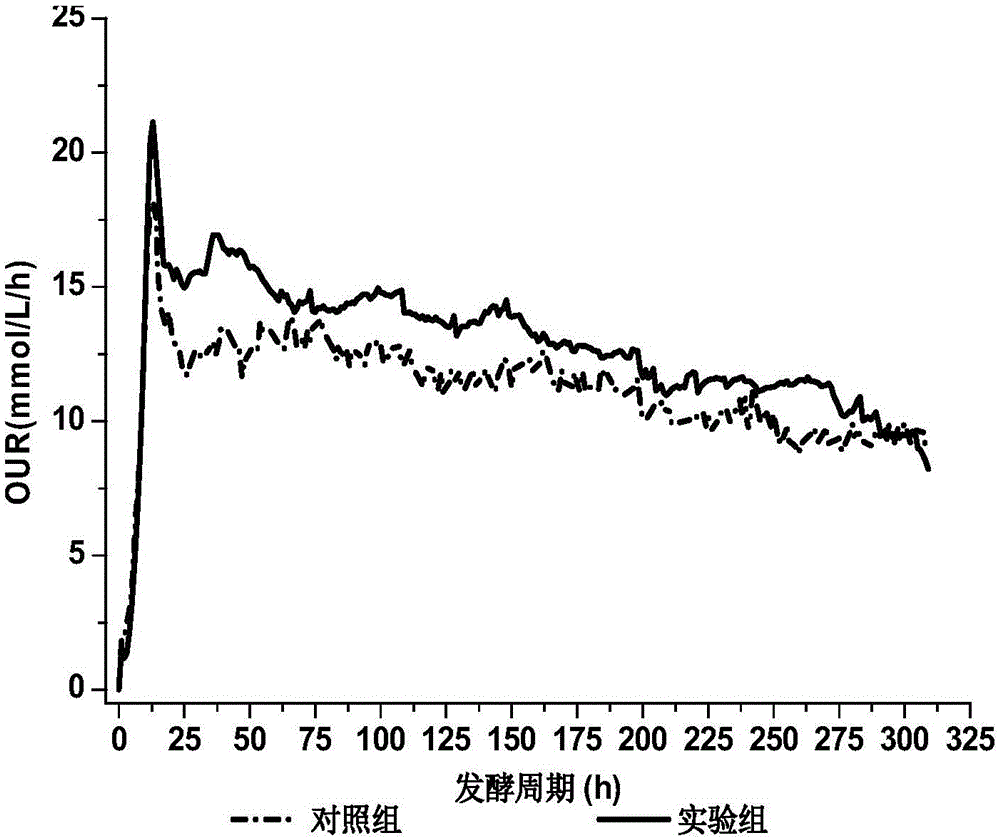

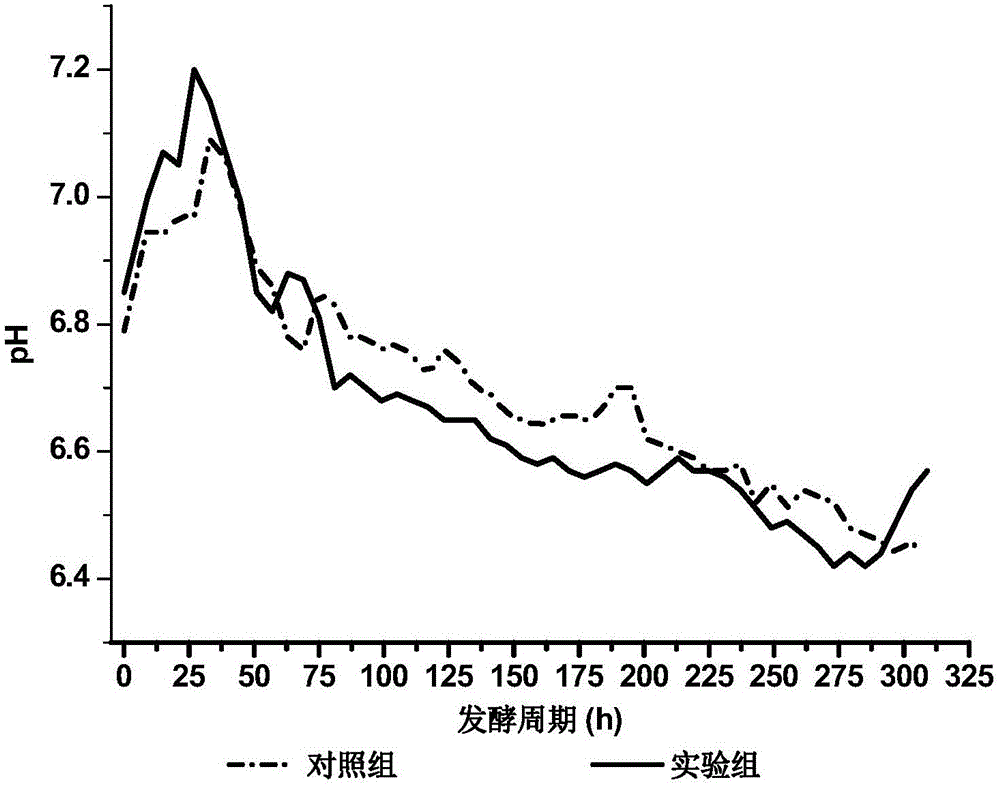

[0094] Embodiment 2, fermentor cultivation

[0095] The 100L advanced fermenter is used as a seed tank, and the 500L advanced fermenter is used as a fermenter. The fermentation medium of the control group was not changed, and 0.1 g / L of calcium chloride was added to the fermentation medium of the experimental group.

[0096] seed jar

[0097] A 100L high-grade fermenter is used. After digestion, the pH was adjusted to 7.5, the volume of the fermentation broth was 60L, the culture temperature was 28°C, the tank pressure was 0.05MPa, the ventilation volume was 1:1.5 (vvm), and the fermentation was started for 25 hours with stirring at 300rpm. The method is pipe inoculation, and the amount of seed conversion is 8%. There were no other manipulated variables during the culture, ie no calcium chloride addition, no induction.

[0098] Fermenter

[0099] A 500L high-grade fermenter is used. After digestion, the pH was adjusted to 7.2, the volume of the fermentation broth was 300...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com