Complicated metallurgical process simulation calculation method and system

A technology of process simulation and calculation method, which is applied in the field of process engineering, can solve problems such as high initial value requirements, high dimensionality, and difficulty in knowing analytical properties, so as to achieve the effect of not being precocious and increasing diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

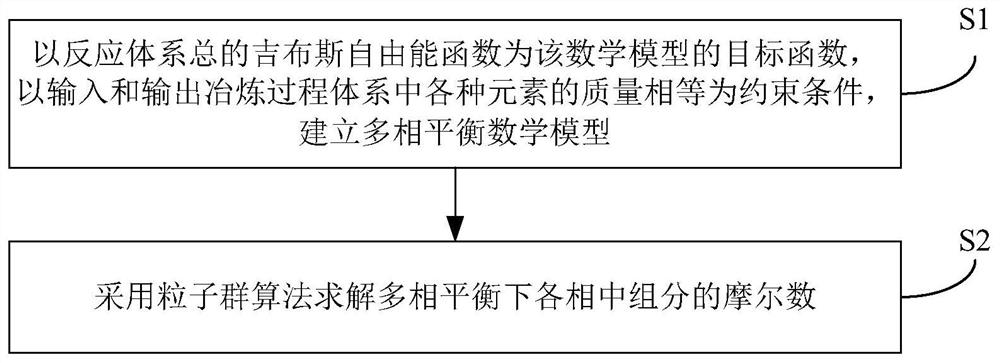

[0042] This embodiment takes copper smelting as an example, and discloses a complex metallurgical process simulation calculation method, such as figure 1 shown, including:

[0043] Step S1, taking the total Gibbs free energy function of the reaction system as the objective function of the mathematical model, and taking the equal mass of various elements in the input and output smelting process system as constraints, to establish a multiphase equilibrium mathematical model.

[0044] In the copper smelting process, the total Gibbs free energy of the reaction system can be calculated by the following formulas (1) and (2):

[0045] G(n,T,P)=G 1 (n,T,P) Matte +G 2 (n,T,P) Slag +G 3 (n,T,P) Gas (1)

[0046]

[0047] In the above formula (1), G(n,T,P), G 1 (n,T,P) Matte , G 2 (n,T,P) Slag , G 3 (n,T,P) Gas are the total Gibbs free energy in the reaction system, and the Gibbs free energy of copper matte phase, slag phase and gas phase, respectively. And in formula (2...

Embodiment 2

[0148] In order to test the performance of the algorithm, the test function of the following formula (23) was selected from the literature, and its function form is similar to the multiphase equilibrium mathematical model type of the copper smelting process designed in this design, which is representative to a certain extent.

[0149]

[0150] where c 1 =-6.089, c 2 =-17.164, c 3 =-34.054,c 4 =-5.914,c 5 =-24.721,c 6 =-14.896, c 7 =-24.100,c 8 =-10.708,c 9 =-26.662,c 10 =-22.179.

[0151] The COPSO algorithm was proposed by Aguirre A H, Zavala A M et al., and the ISRES algorithm was proposed by Runarsson and Yao. It is compared with the test results of HLPSO for the above test functions as shown in Table 1 below.

[0152] Table 1:

[0153]

[0154] The exact solution given in the literature is:

[0155] x*=(0.0407, 0.1477, 0.7832, 0.0013, 0.4853, 0.0007, 0.0274, 0.018, 0.0373, 0.0968)

[0156] However, using HLPSO can converge to the above optimal solution e...

Embodiment 3

[0159] In a domestic copper smelter, the basic parameters in the relevant production practice process were collected, and a multiphase equilibrium mathematical model was established.

[0160] Through production research, the temperature of the matte and slag phase is about 1200°C, while the gas phase temperature is 1300°C; the copper matte phase mainly includes Cu 2 S, Cu, FeS, FeO, Fe 3 o 4 , Pb, PbS, ZnS, As, Sb, Bi and other components; the slag phase mainly includes FeO, Cu 2 S, Cu 2 O, Fe 3 o 4 , FeS, PbO, ZnO, As 2 o 3 , Sb 2 o 3 、 Bi 2 o 3 , SiO 2 , CaO, MgO, Al 2 o 3 and other components; the gas phase mainly includes SO 2 , S 2 , O 2 , N 2 、H 2 O, PbO, PbS, Zn, ZnS, As2, AsO, AsS, SbO, SbS, BiO and other components.

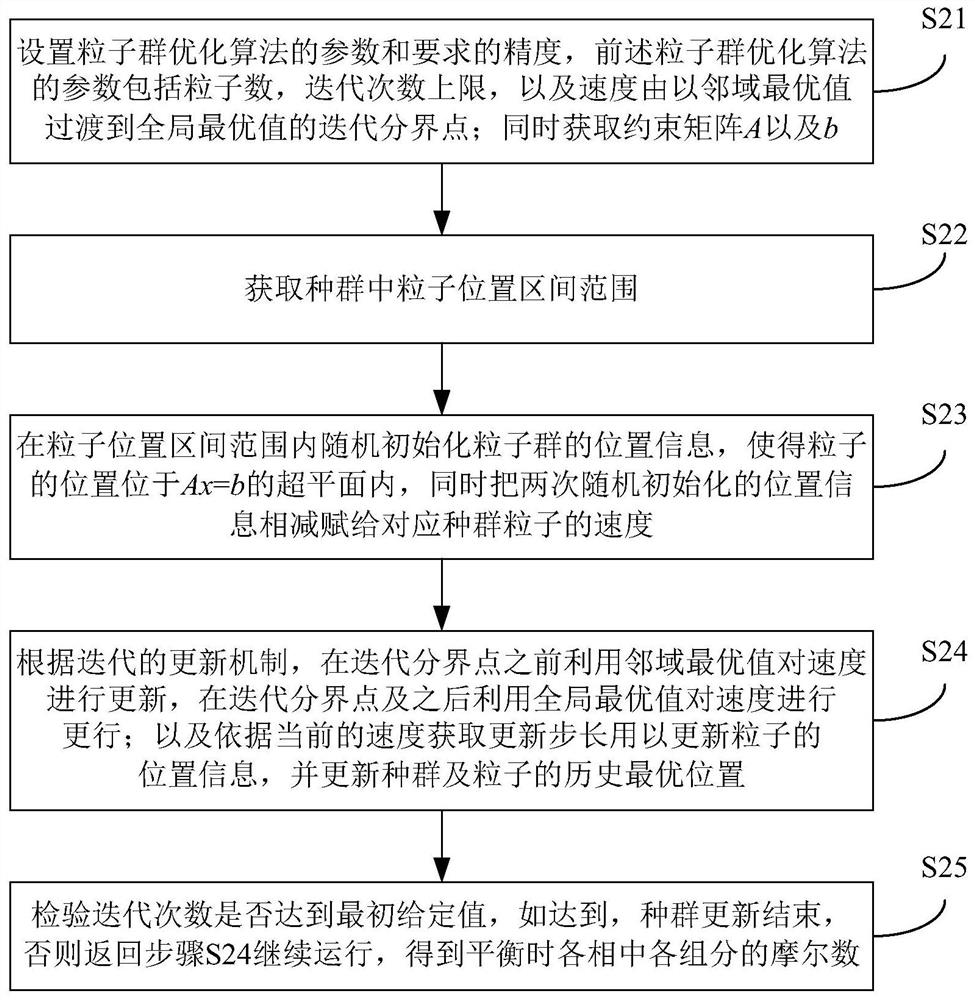

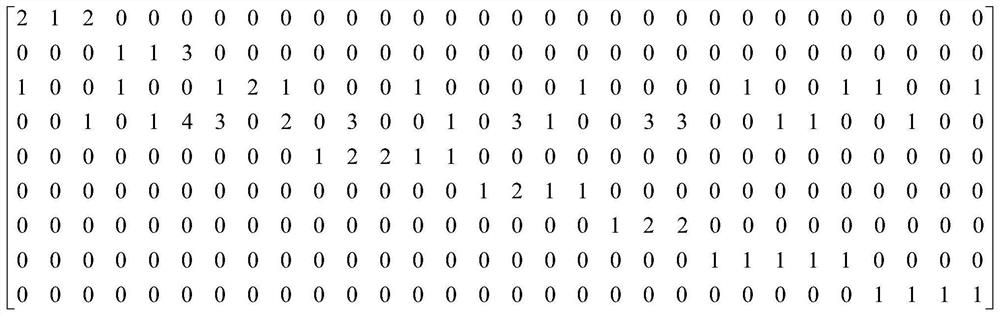

[0161] On the basis of the above, a mathematical model is established through the thermodynamic multiphase equilibrium theory, the optimization objective function and constraint conditions are determined, and the calculation is perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com